Lamp body structure for reflecting device and its manufacturing method

A technology of a reflective device and a manufacturing method, which is applied to identification devices, instruments, etc., can solve the problems of difficult quality control, complicated manufacturing operations, uneven quality, etc., and achieve the effect of improving economic efficiency and changing manufacturing and structure methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

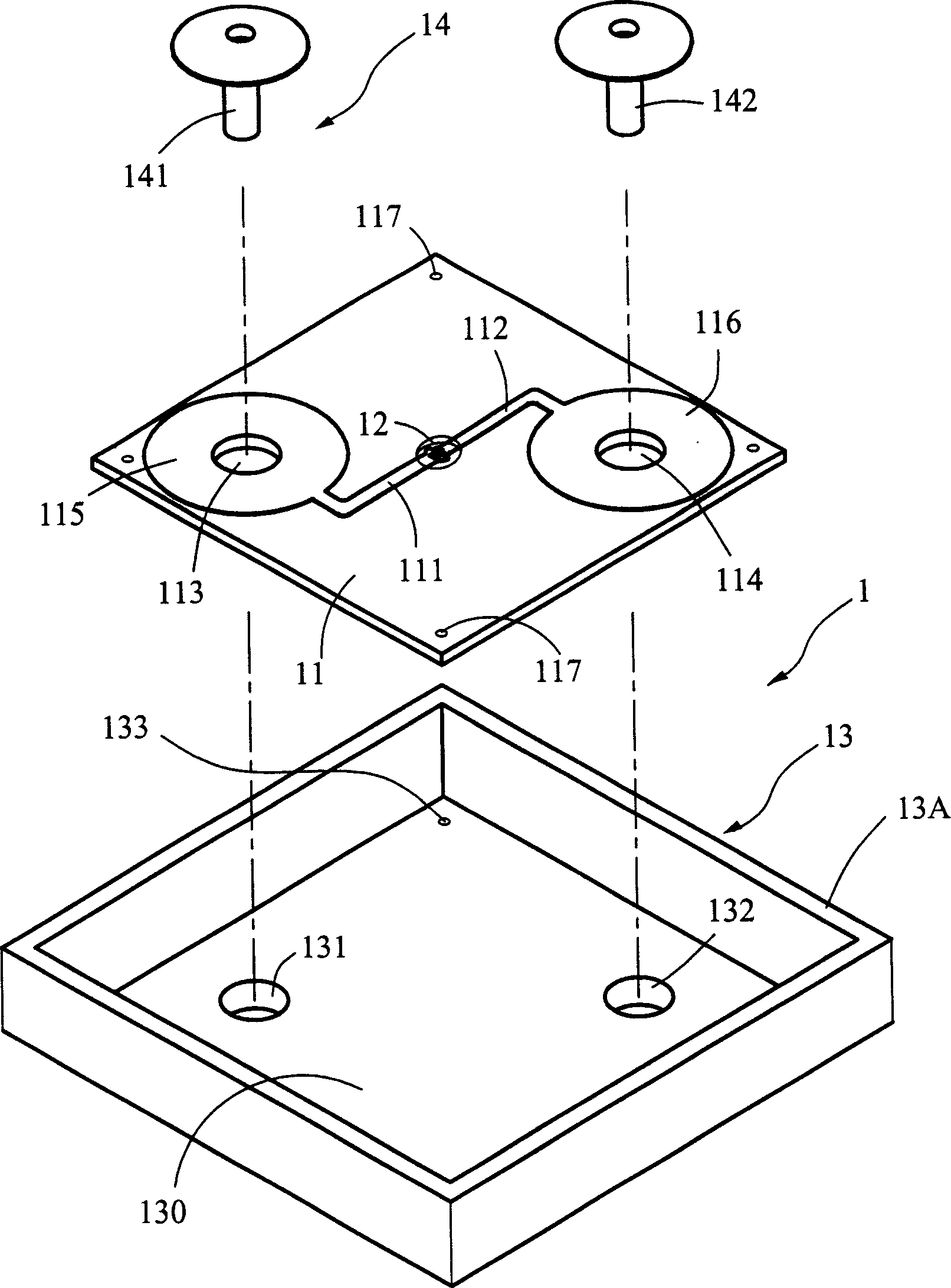

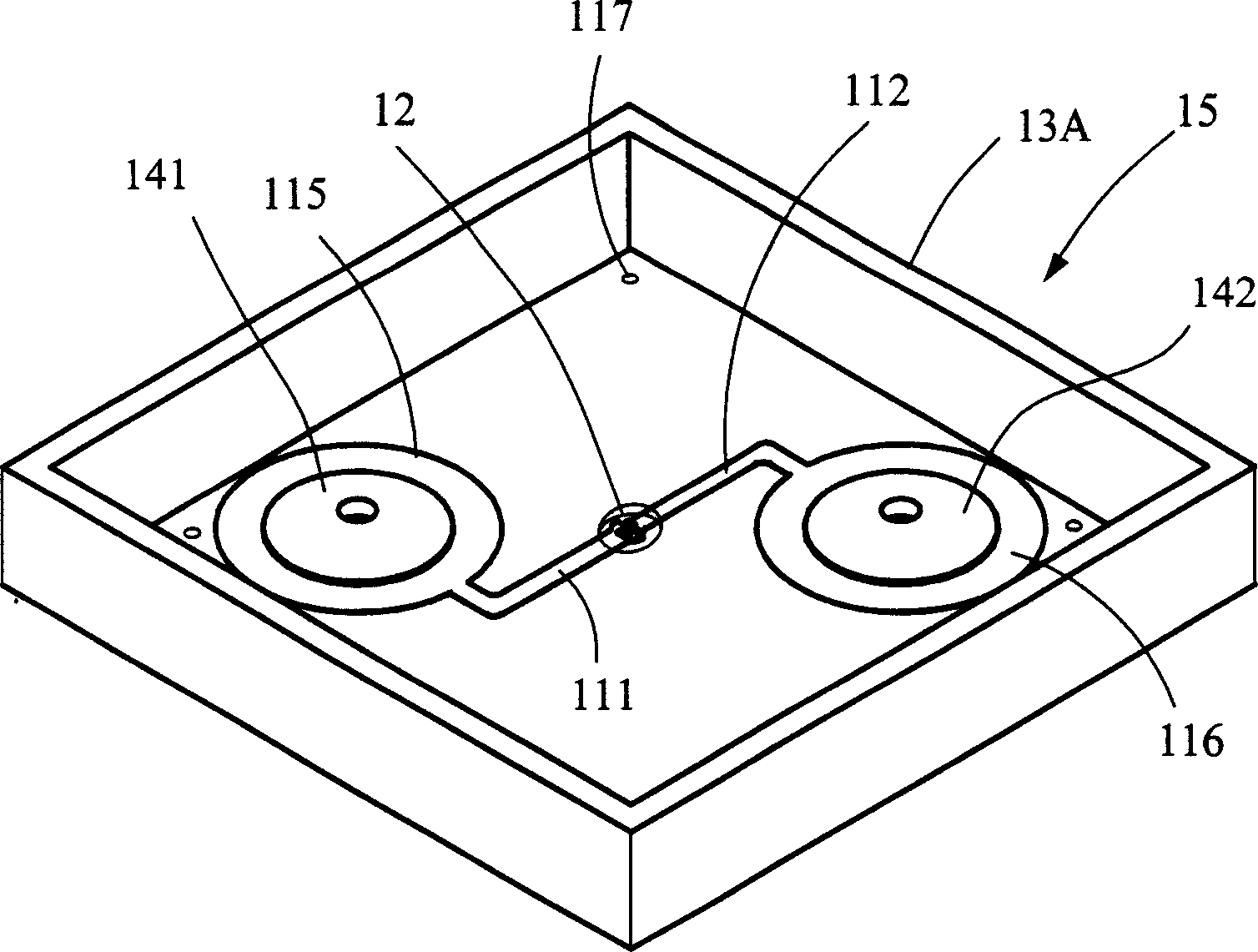

[0109] Please refer to FIG. 21 , which is the first embodiment of the heat-press packaging manufacturing method of the lamp body unit 1 of the present invention. The substrate 11 , the LED lamp group 12 and the rivet group 14 are assembled and fixed on the base 13A to form the base unit. 15 (the base units 15A, 15B are the same), then the base 13A is covered with a cover plate 19, and the side of the cover plate 19 opposite to the base 13A is provided with a plurality of abutment posts 191 for the base. 13A produces a supporting effect. When the sealing plate 19 is covered on the base 13A, it is welded and fixed by a high-frequency or ultrasonic welding machine, so that the sealing plate 19 and the base 13A are fused together to form a protruding rivet The lamp body unit 1 of 141, 142, such as Figure 22 shown.

[0110] another example Figure 23 , 24, the accommodating space 130 of the base 13A is provided with a pair of grooved positioning columns 138 for inserting and pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com