Hammering mechanism of hammering sleeve washers

A washing machine and sleeve-type technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inconvenient picking and placing of clothes, loud noise, easily damaged clothes and beating mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

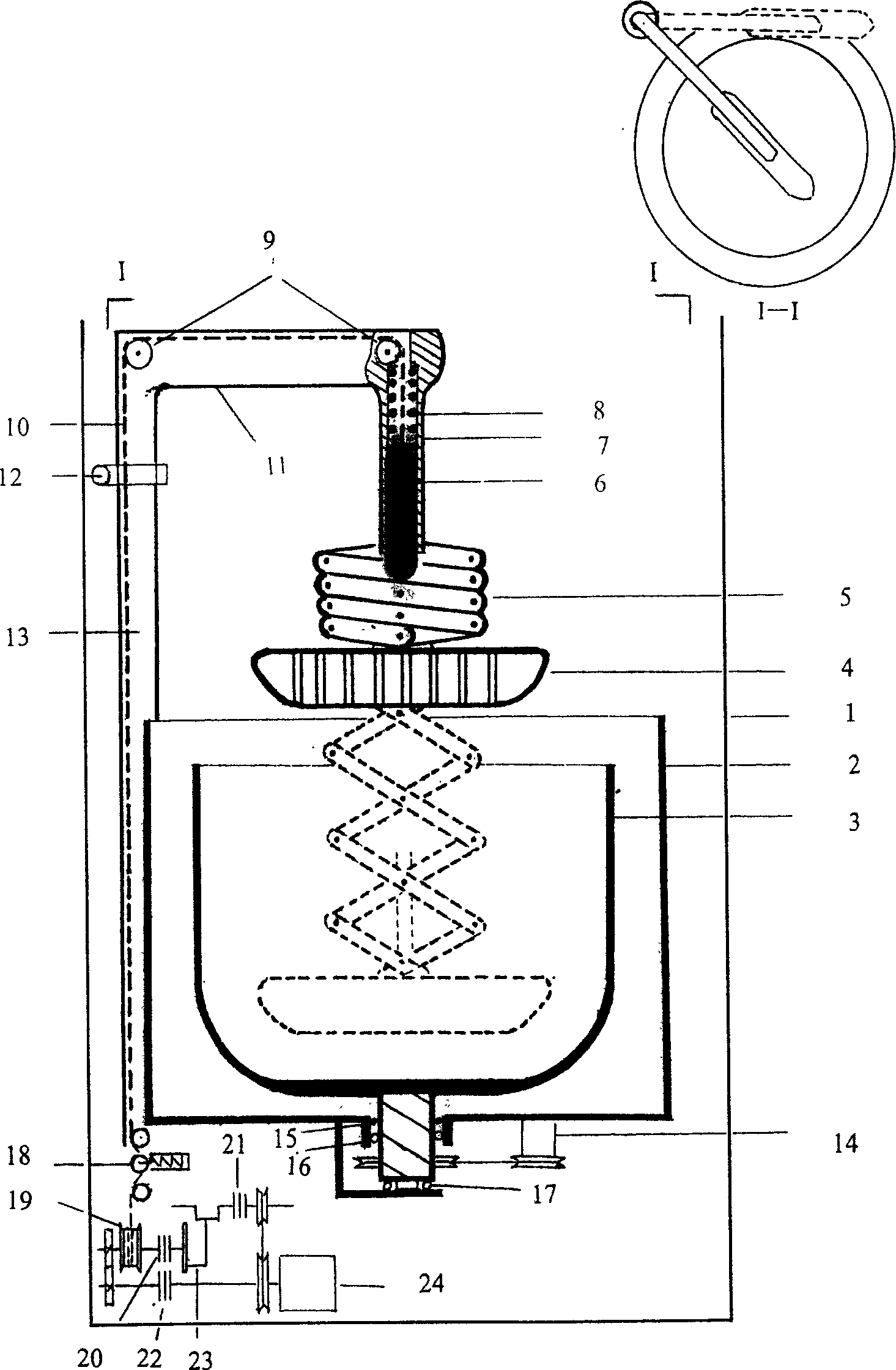

[0014] See attached drawing 1 for the beating structure of the washing machine

[0015] Among the figure, (1) washing machine shell (2) outer barrel (3) inner barrel (4) impact hammer (5) connecting rod mechanism (6) sliding shaft (7) sliding shaft sleeve (8) spring (9) pulley ( 10) Wire rope (11) rocker arm (12) rocker arm drive mechanism (13) vertical shaft of rocker arm mechanism (14) inner barrel drive motor and reducer (15) water seal (16) bearing (17) thrust bearing (18) ) tensioner and interlocking switch (19) axle (20) clutch (21) clutch (22) clutch (23) crank rocker (24) impact hammer drive motor and reducer

[0016] The rocker mechanism is composed of the vertical shaft 13 of the rocker mechanism, the rocker arm 11 and the drive motor 12. The vertical axis of the rocker mechanism is fixed on the shell 1 of the washing machine, and the vertical sliding shaft sleeve 7 is installed on the lower end of the rocker arm 11. Move the hammer away from the mouth of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com