Control for pipeline gas distribution system

A distribution system, management and control technology, applied in the direction of electric fluid pressure control, fluid pressure control, flow control, etc., can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

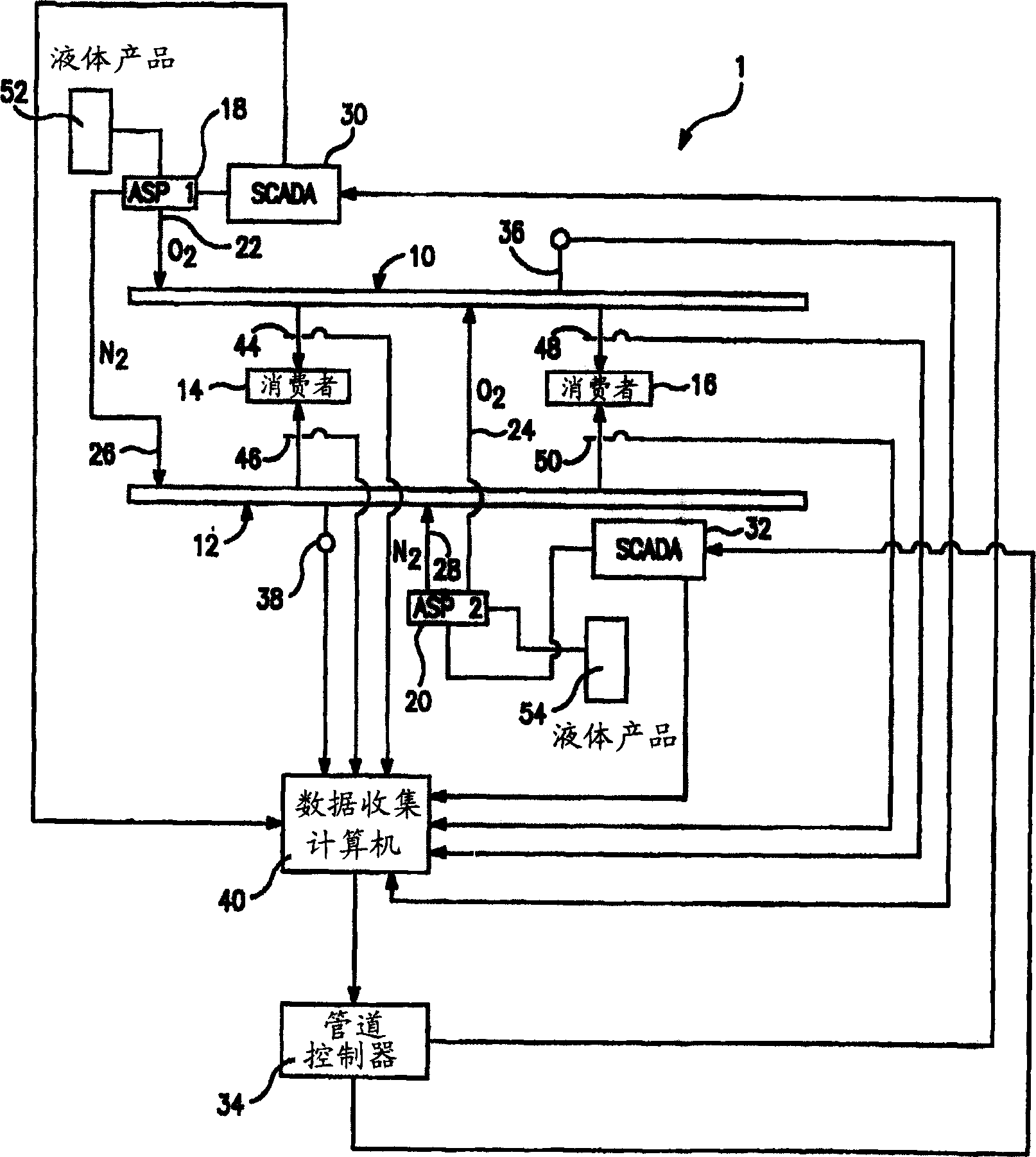

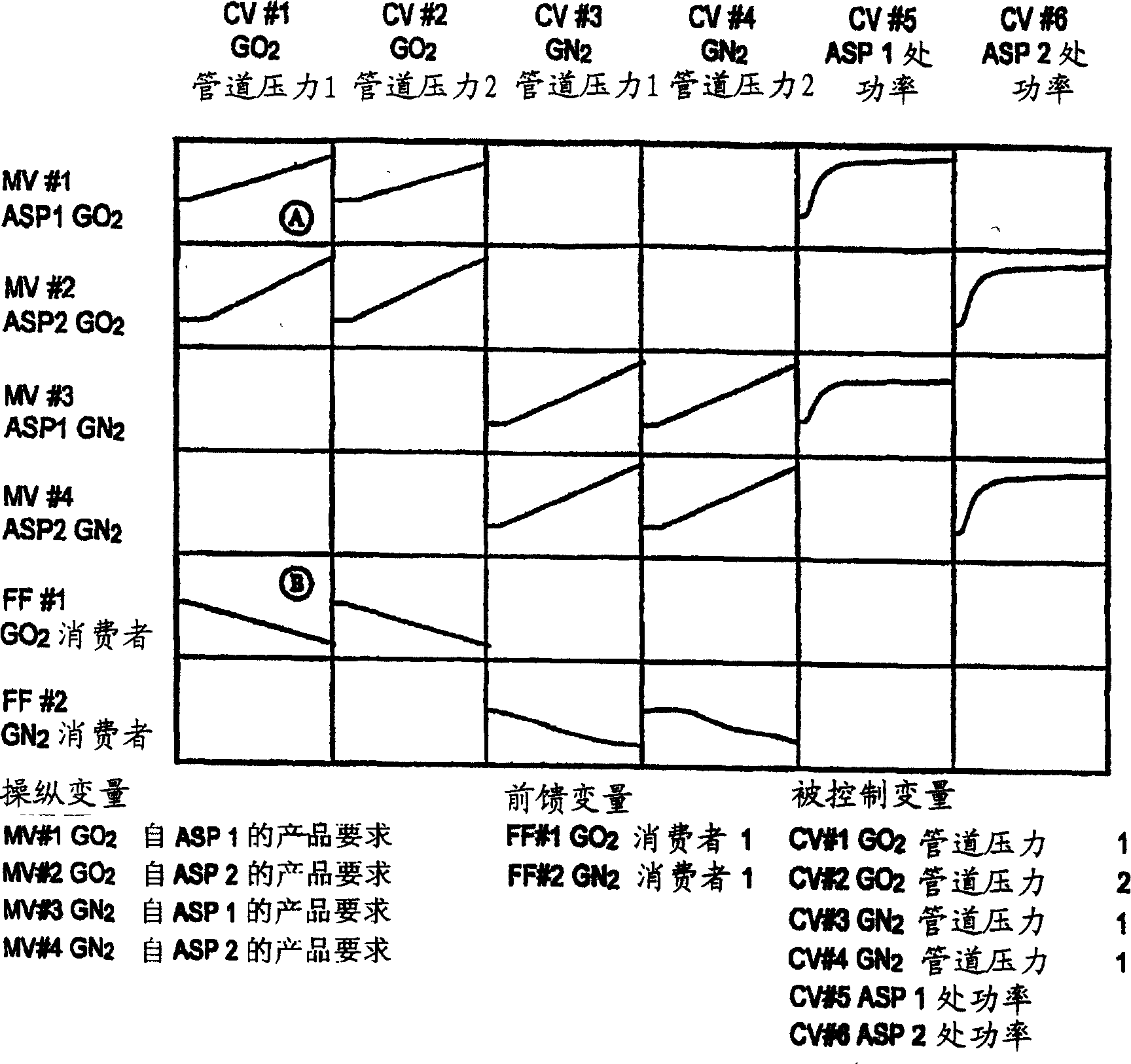

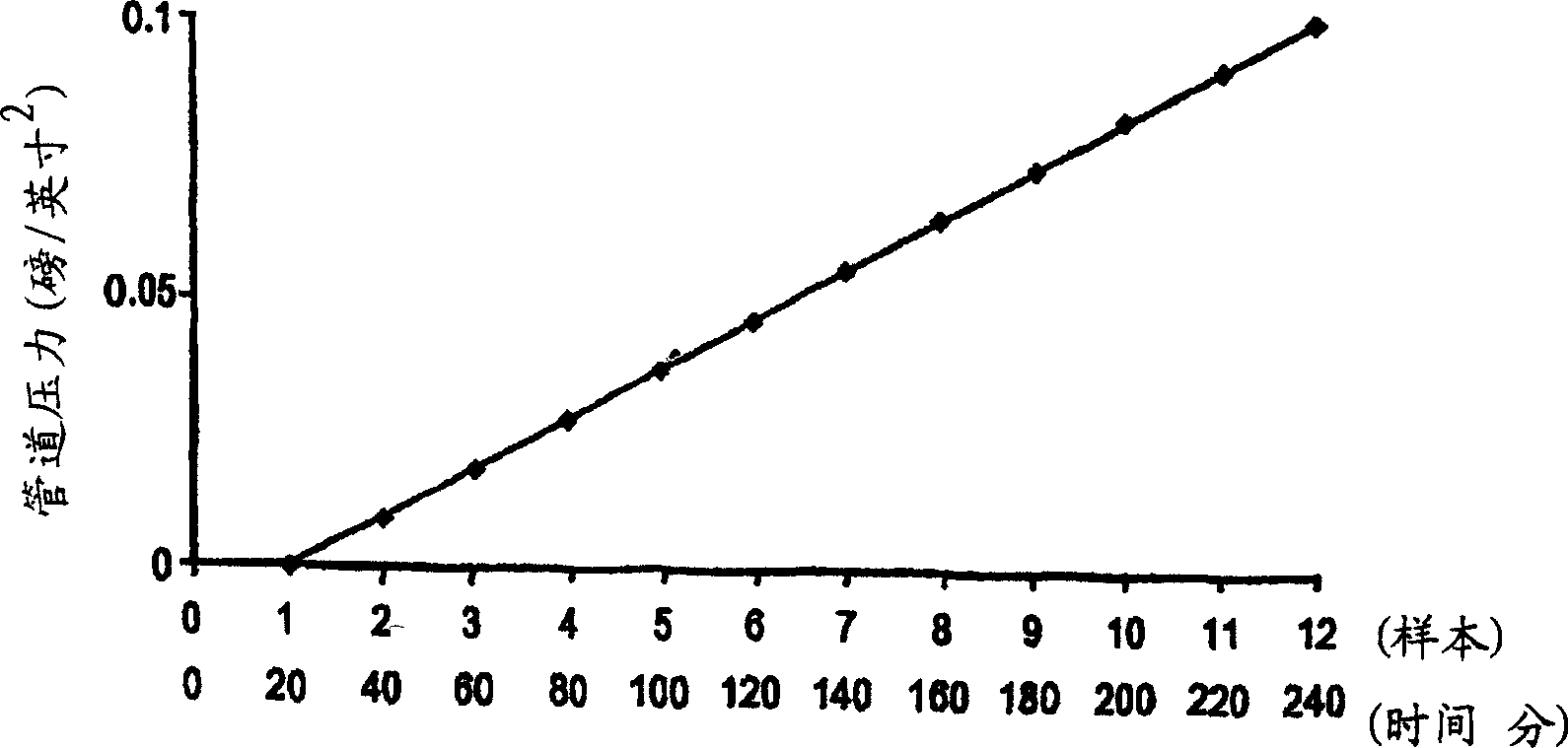

[0026] refer to figure 1 , illustrates a gas distribution system 1 controlled according to the present invention. It should be understood that the gas distribution system 1 is illustrated for exemplary purposes and that the system to be controlled in accordance with the invention may be more complex or simpler than that illustrated.

[0027] The gas distribution system 1 comprises pipeline sections 10 and 12 supplying gaseous oxygen and gaseous nitrogen to consumers 14 and 16, respectively. Piping sections 10 and 12 are supplied with gaseous oxygen and nitrogen by air separation plants ( ASP1 and ASP2 ) 18 and 20 . Air separation plants 18 and 20 are connected to pipeline sections 10 and 12 by oxygen conduits 22 and 24 and nitrogen conduits 26 and 28 . In this regard, the purity of the supplied oxygen and nitrogen depends on the type of air separation plant used to meet the needs of consumers 14 and 16 .

[0028]Air separation units 18 and 20 separate oxygen and nitrogen fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com