Claw-pole type generator

A generator and claw pole type technology, applied in the field of claw pole type generators for bicycles, to achieve the effect of reducing assembly cost and being easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

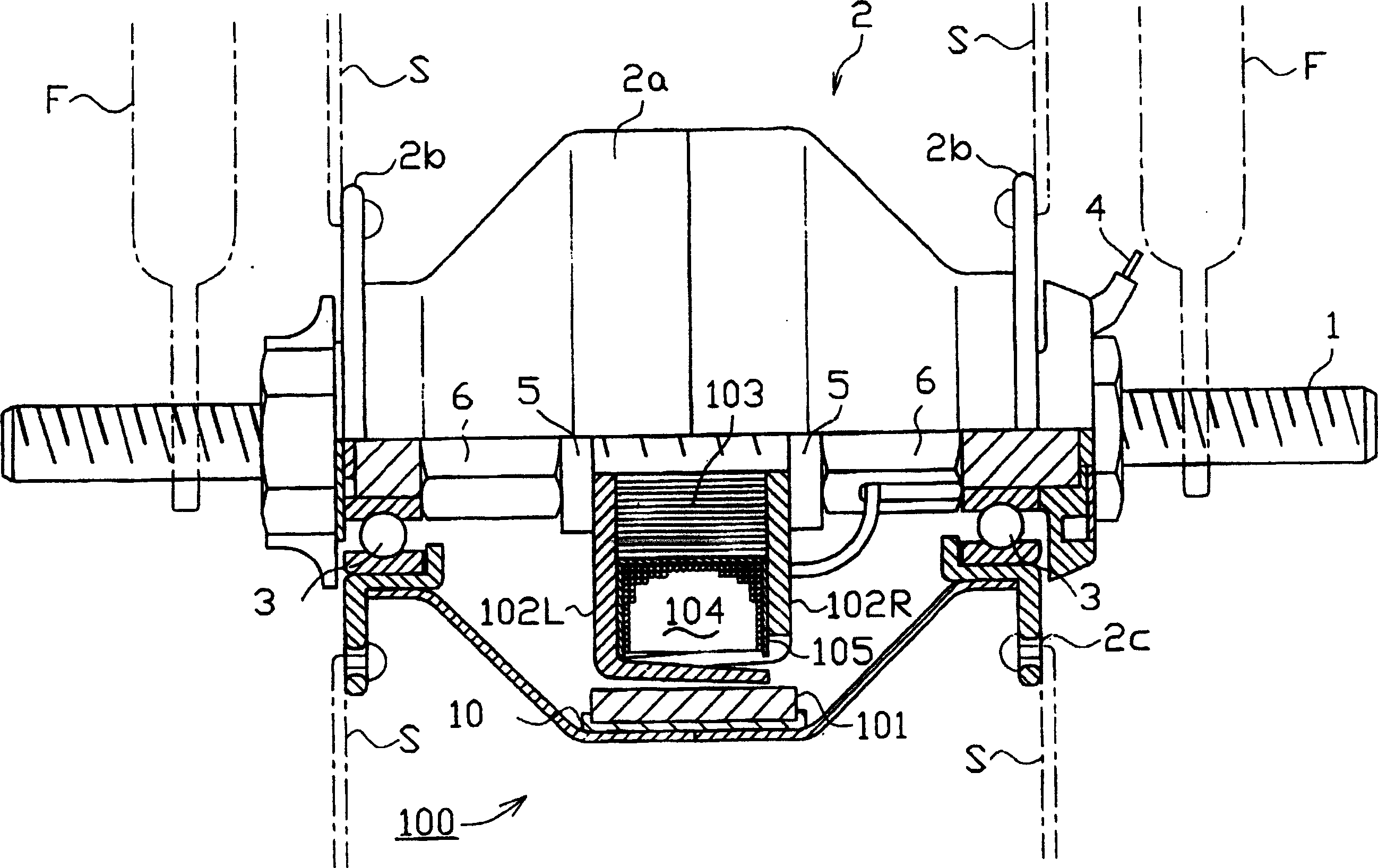

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

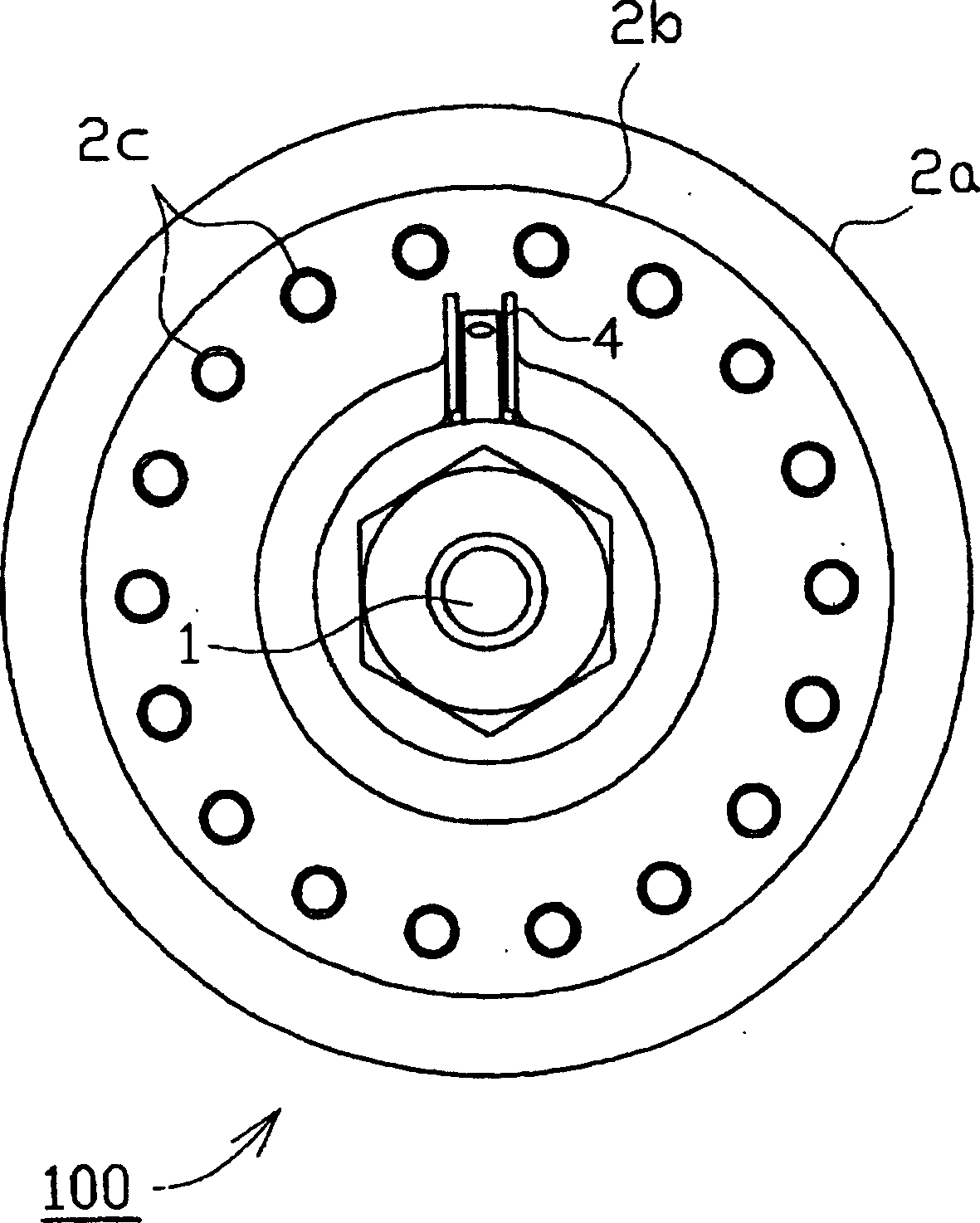

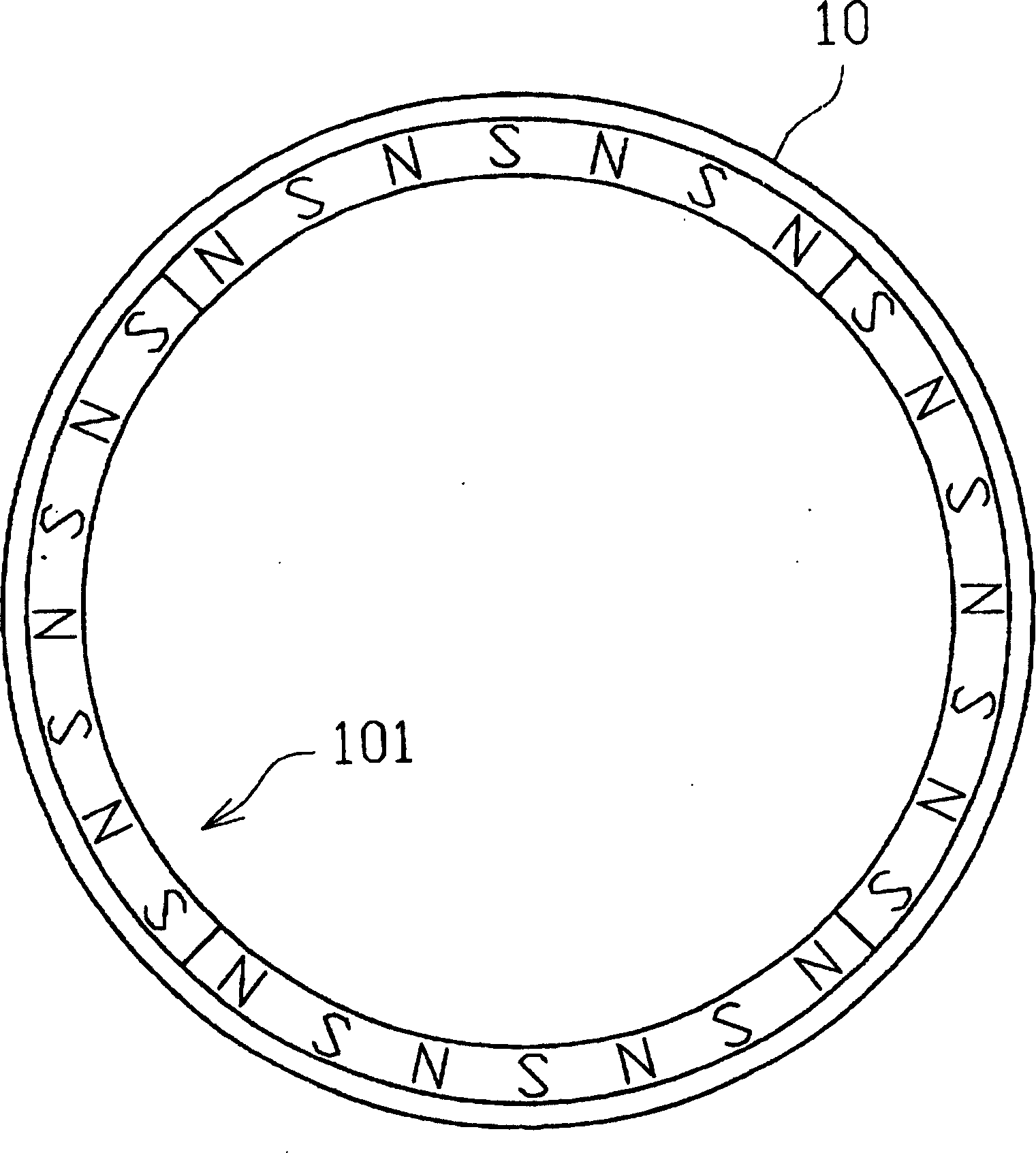

[0037] figure 1 The overall configuration of a claw pole generator 100 according to an embodiment of the present invention is shown. Such as figure 1 As shown, the claw pole generator 100 has a ring-shaped permanent magnet 101, two stator yokes 102L and 102R arranged opposite to the permanent magnet 101, a core yoke 103 magnetically connecting the stator yokes 102L and 102R, and a A coil 104 is provided around the core yoke 103 . The thus constituted claw pole generator 100 is fixed to a hub shaft 1 of any known bicycle wheel, and the claw pole generator 100 constitutes a bicycle hub generator. In addition, a male thread / external thread is formed on the hub shaft 1, and the hub shaft 1 is fixed to a fork F for a bicycle wheel by a nut or the like.

[0038] A hub cover 2 is rotatably connected to the hub shaft 1 via a bearing 3 . The hub cap 2 has a drum hub 2a an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com