Back light module

A backlight module and backplane technology, applied in optics, electric light sources, nonlinear optics, etc., can solve the problems of unavailability, reduce complexity and cost, and achieve reduced usage, reduced complexity and cost, and stable combination Effects of complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

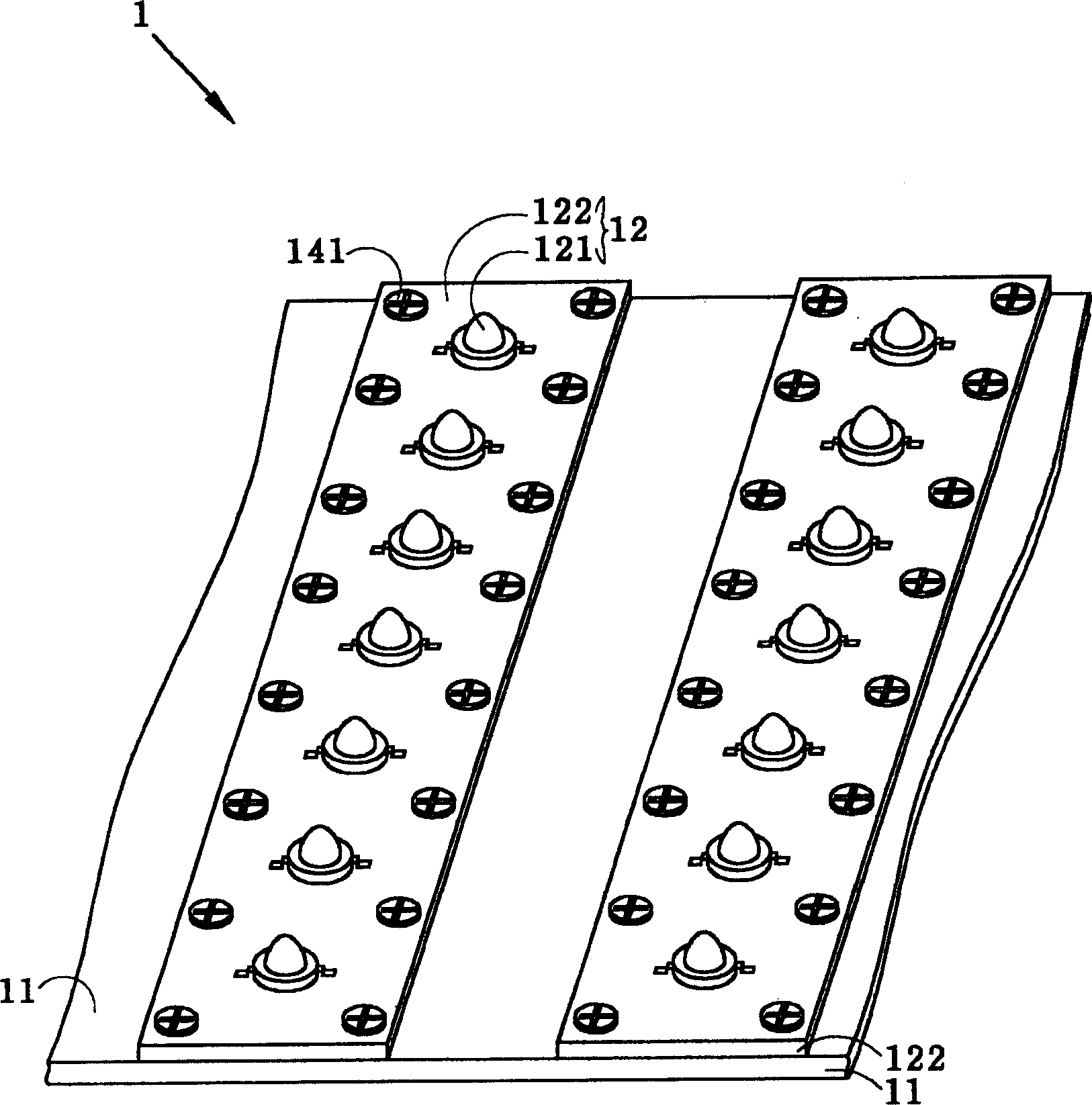

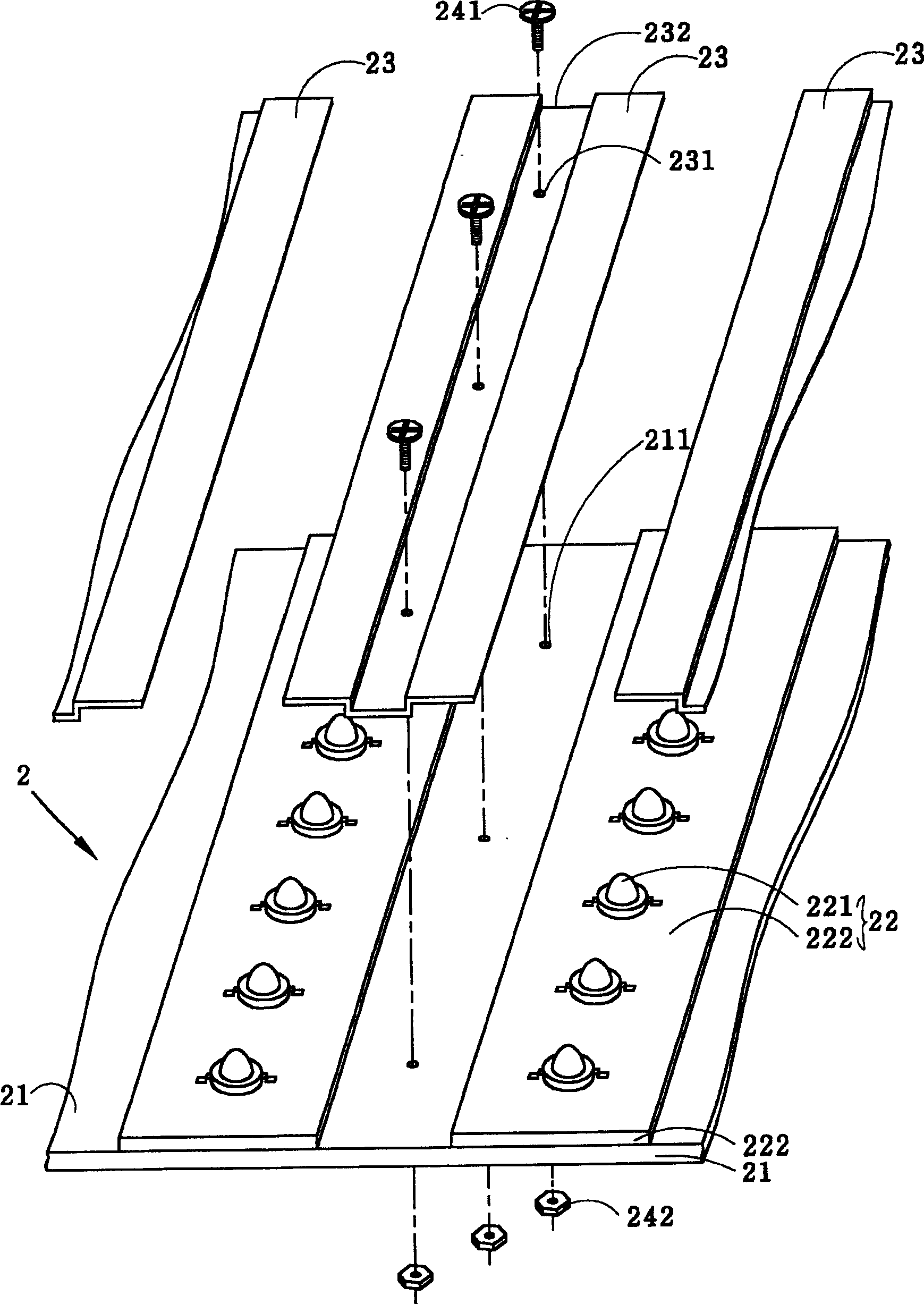

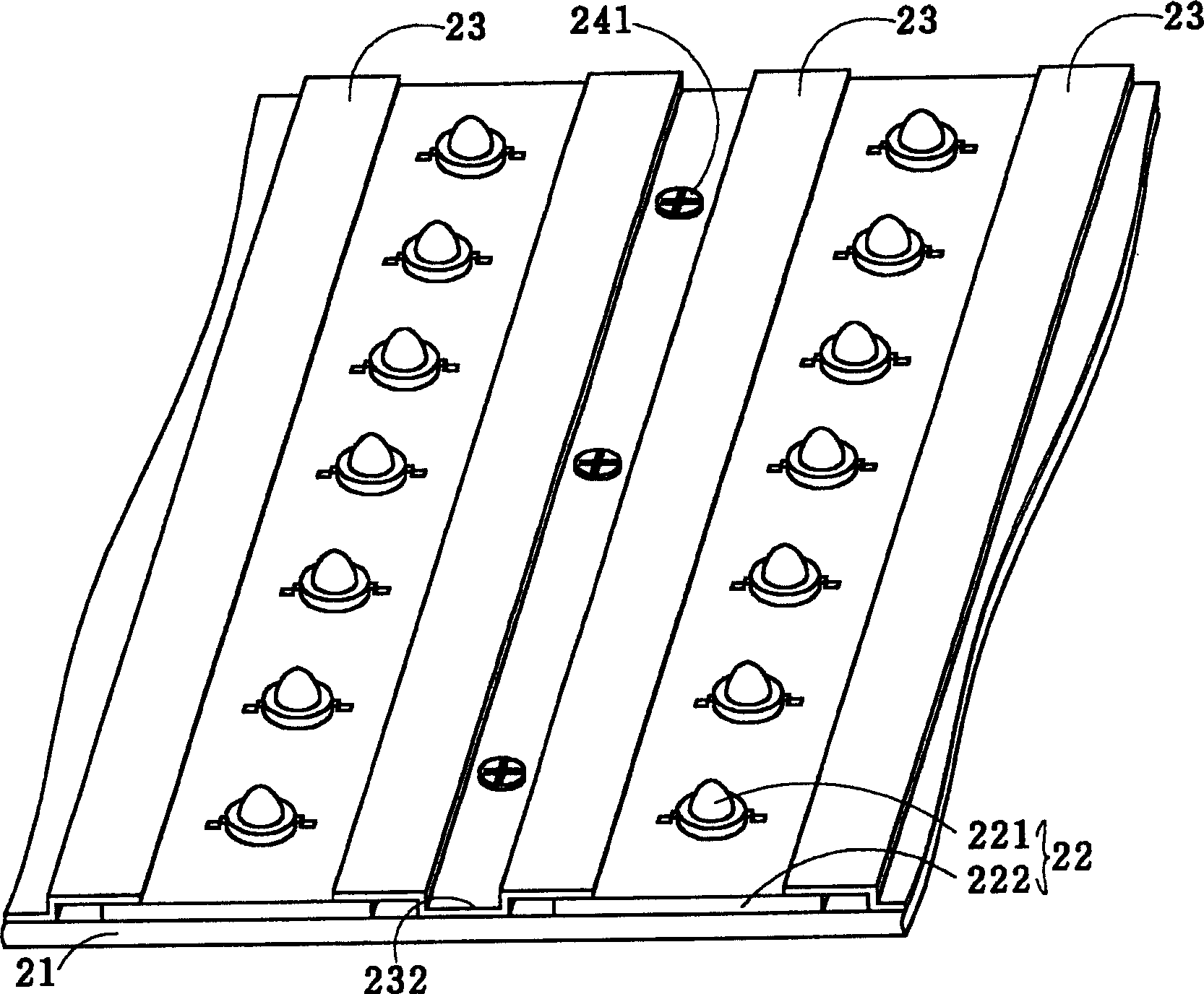

[0022] The following is a detailed description of the implementation of the backlight module of the present invention according to the accompanying drawings. The description of the backlight module and the light-emitting unit itself in the following description does not include the description of the detailed structure, composition and operating principle. The prior art is only cited here with emphasis to help explain the present invention. Moreover, the drawings of the relevant light emitting units in the following texts are not drawn according to the actual scale, and their function is only to express the characteristics of the present invention. Secondly, when each element or structure in the drawings of the embodiments of the present invention is described, it should not be regarded as a limited cognition, that is, when the following description does not particularly emphasize the limitation on the number, the spirit of the present invention and The scope of application ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com