Ultra-low noise cooling tower with integrated structure dropping plate and water tank

A technology of ultra-low noise and water collection tank, which is applied in the direction of water shower coolers, sound-generating equipment, lighting and heating equipment, etc., can solve the problems of insignificant noise reduction effect, affecting the air volume entering the tower, and reducing the sound of water spraying, etc., achieving remarkable Economic and social benefits, good prospects for popularization and application, and the effect of reducing noise from water towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

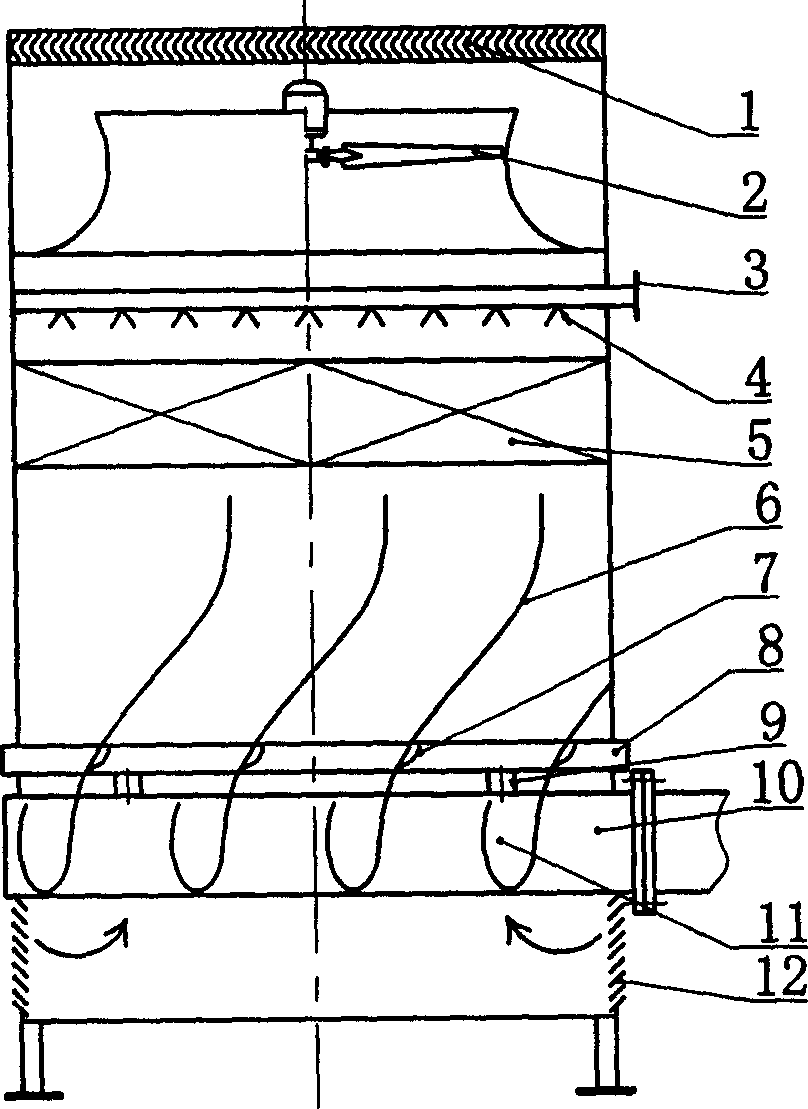

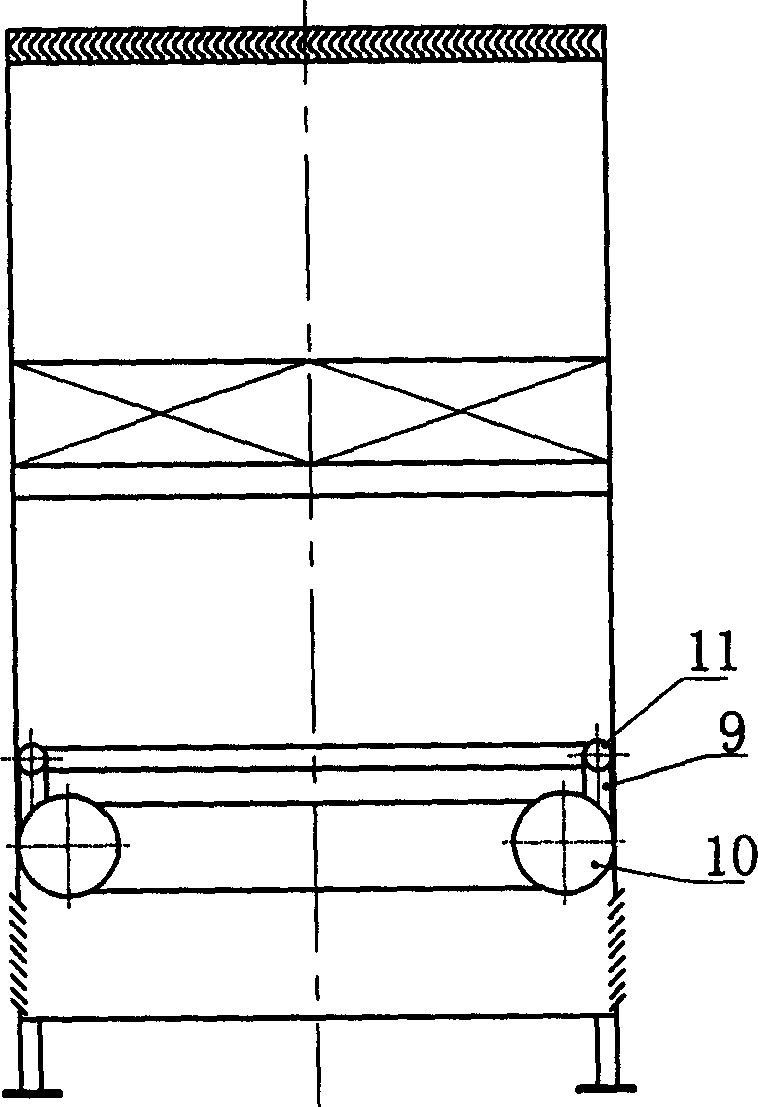

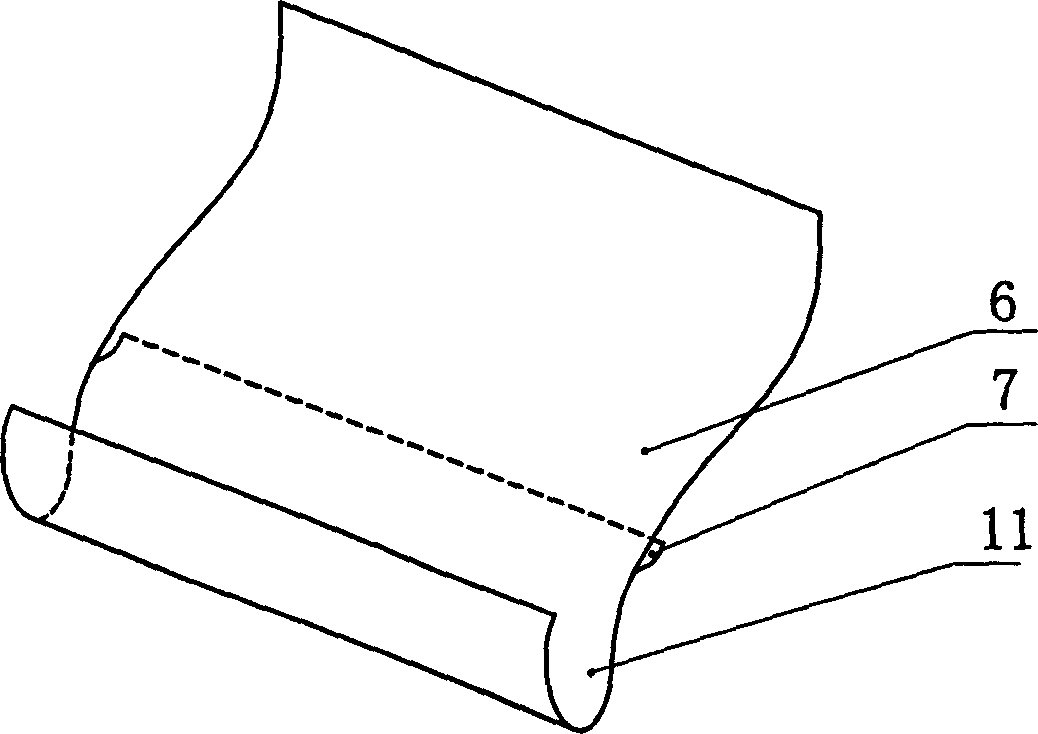

[0016] Such as figure 1 , figure 2 , image 3 Shown, the present invention comprises water eliminator 1, blower fan 2, water inlet pipe 3, nozzle 4, packing 5, small drain pipe 8, connecting pipe 9, large drain pipe 11, and by dripping water plate 6 big sump 11 and small The integrated structure composed of the sump 7, the dripping plate 6 is a double-curvature arc-shaped plate, bent at the bottom to form a large sump 11 with an elliptical cross-section, the small sump 7 is located on the back of the dripping plate 6, and the large sump 11 Above, the dripping board 6, the large sump 11 and the small sump 7 are smoothly connected into one, the angle between the small sump 7 and the junction of the dripping board 6 is ≤30°, the dripping board 6, the large sump 11 and small sump 7 integrated structure is to adopt plastics or aluminum all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com