Seat suspension

A technology for suspension devices and seats, which can be applied to seat suspension devices, vehicle seats, seats, etc., and can solve problems such as the ability to lean back or fold forward on the seat, limit the range of front/rear adjustment, etc. , to achieve the effect of reducing the speed and effective damping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

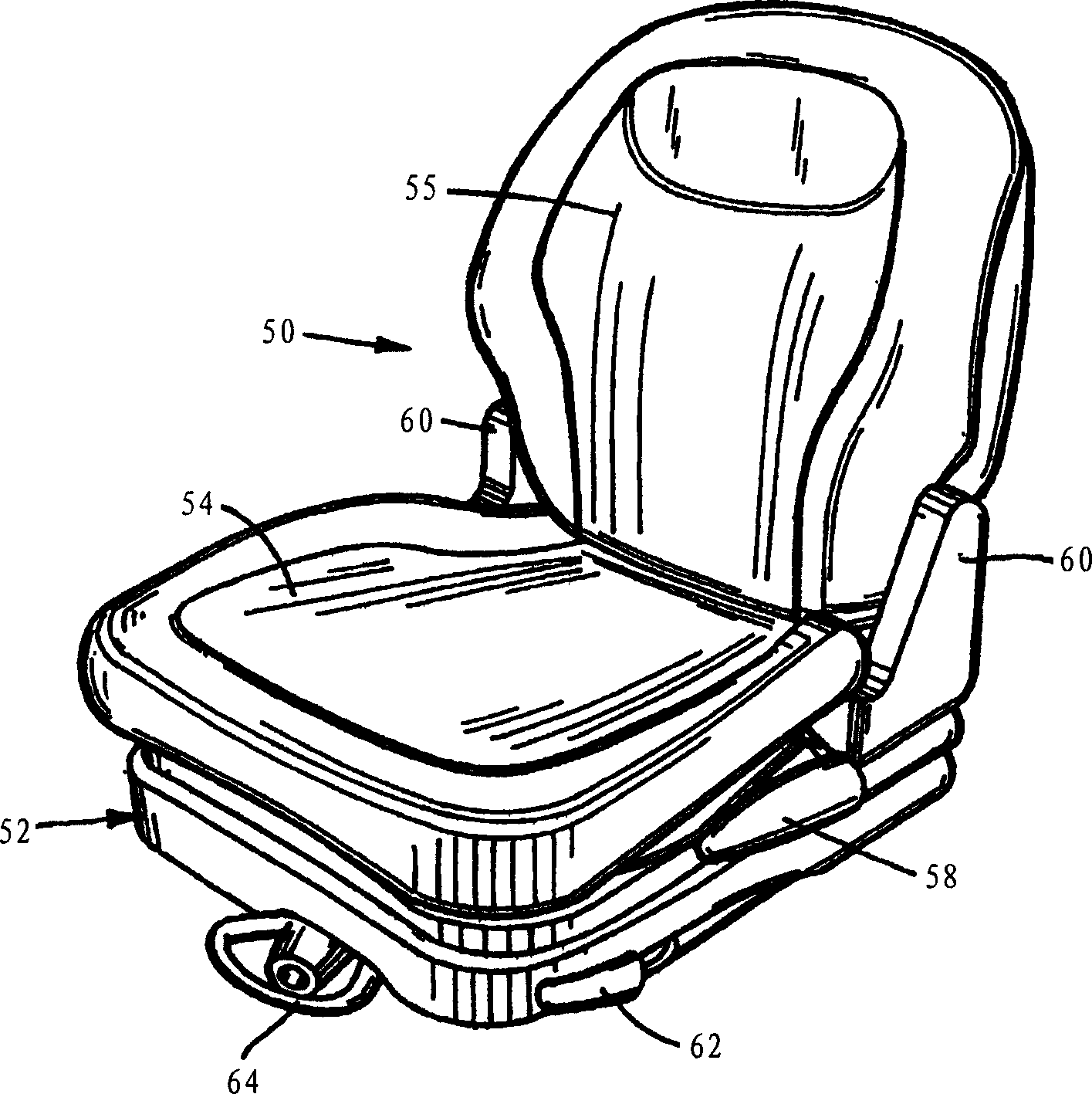

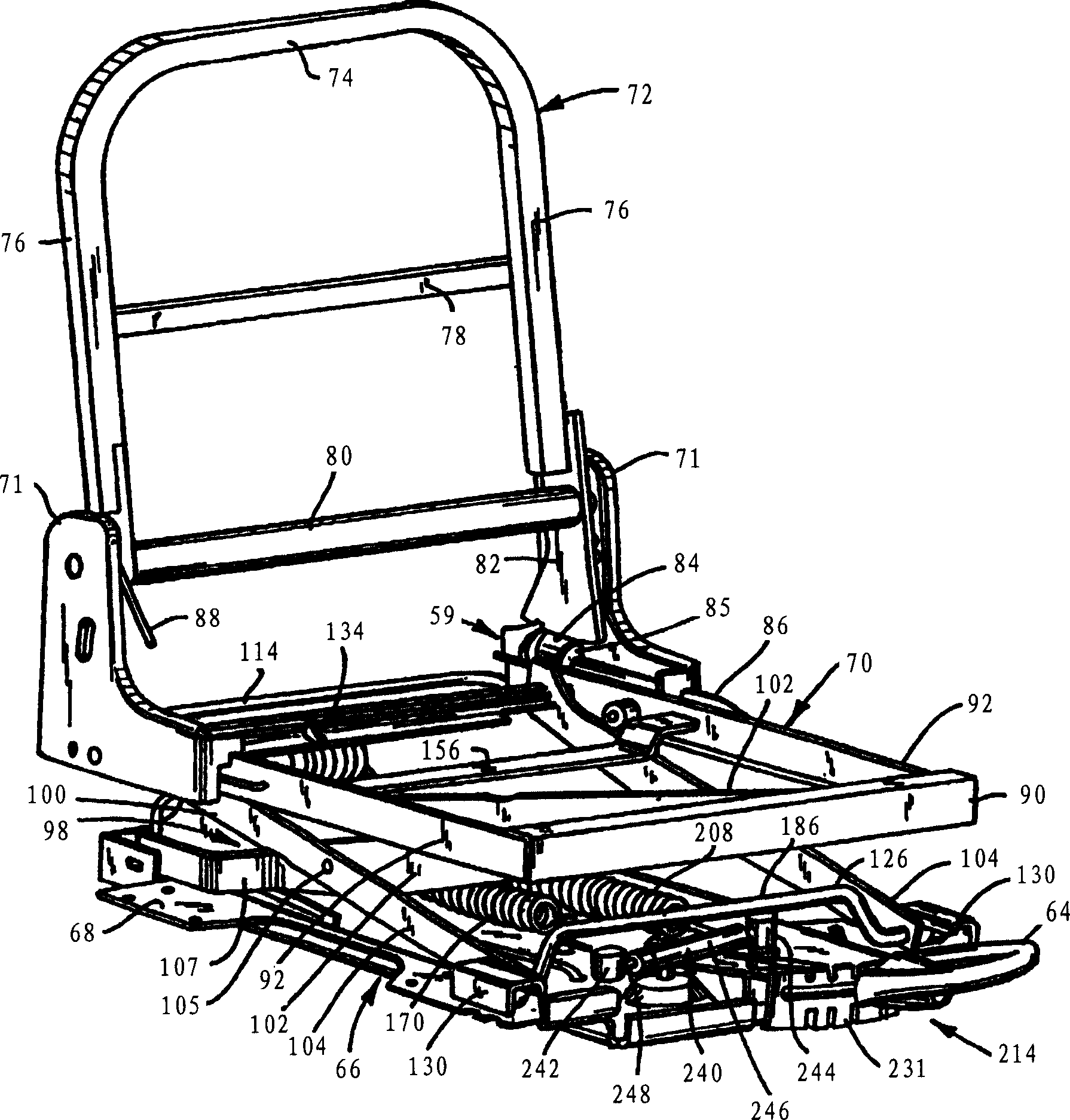

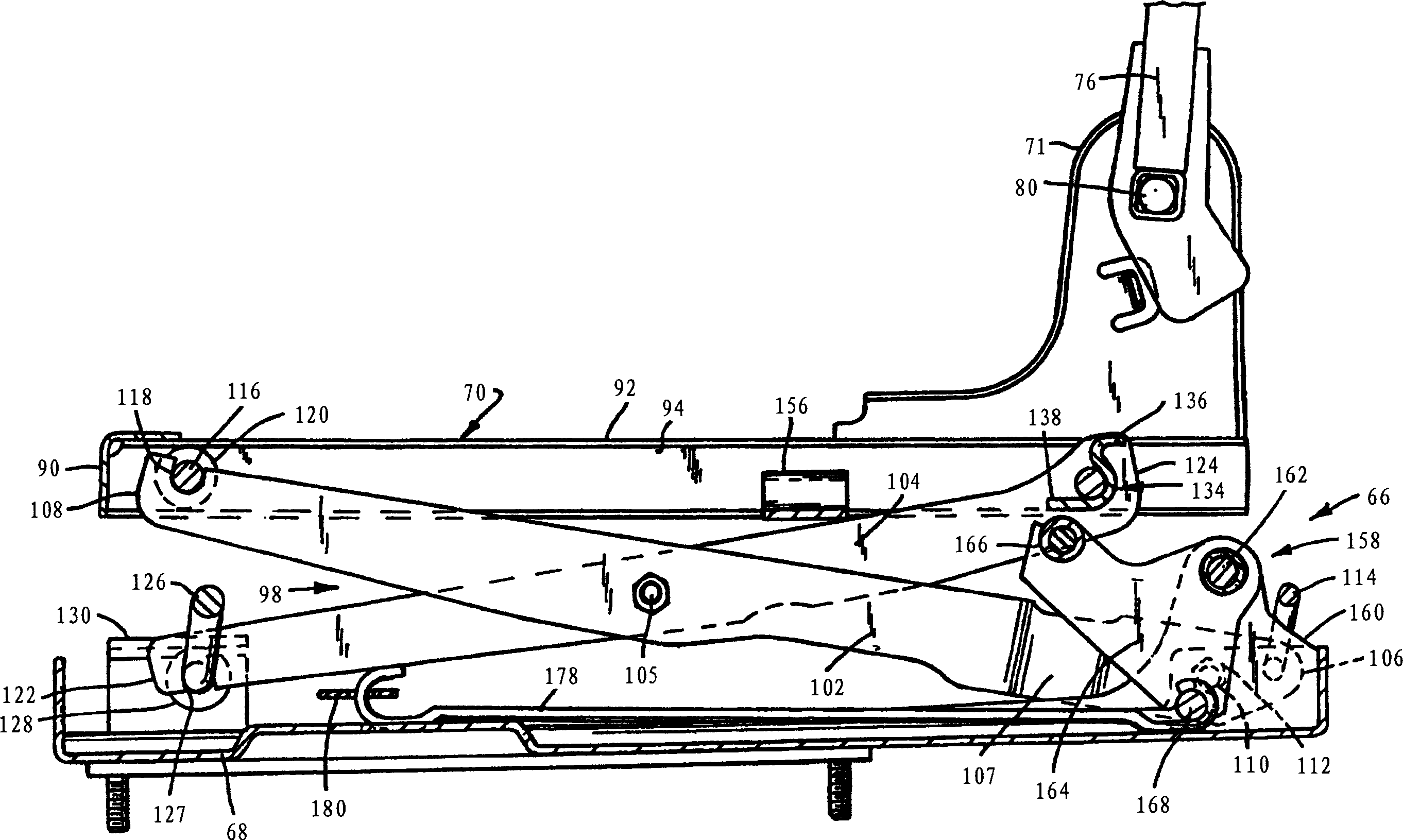

[0059] figure 1 and Figure 14 A seat 50 is shown which includes a frame 52 supporting a seat cushion 54 and a backrest 55 and a suspension base 68 . Although the seat 50 is shown as including a pair of armrests 56 and a seat belt mechanism 57 (as Figure 14 shown), but the seat 50 may take any form of seat used on a machine or vehicle. like figure 2 As shown, frame 52 includes a first handle 58 for controlling pivot mechanism 59 extending between and connected to seat frame 70 and back frame 72 and covered by a pair of cover plates 60 . The hitch base 68 includes a second handle 62, as in the prior art, for actuating a positioning mechanism (not shown) that moves the seat 50 forward or rearward relative to the vehicle on which the seat 50 is mounted. . Also, the hanger base 68 includes a third handle 60 for adjusting the weight adjustment mechanism 214 placed within the hanger base 68 . This will be explained in more detail here.

[0060] now refer to figure 2 , sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com