Motor rotor

A motor and rotor technology, applied in electric components, synchronous motors for single-phase current, manufacturing stator/rotor bodies, etc., can solve problems such as deterioration of motor characteristics, increase in cost, and deterioration of magnetic field intensity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

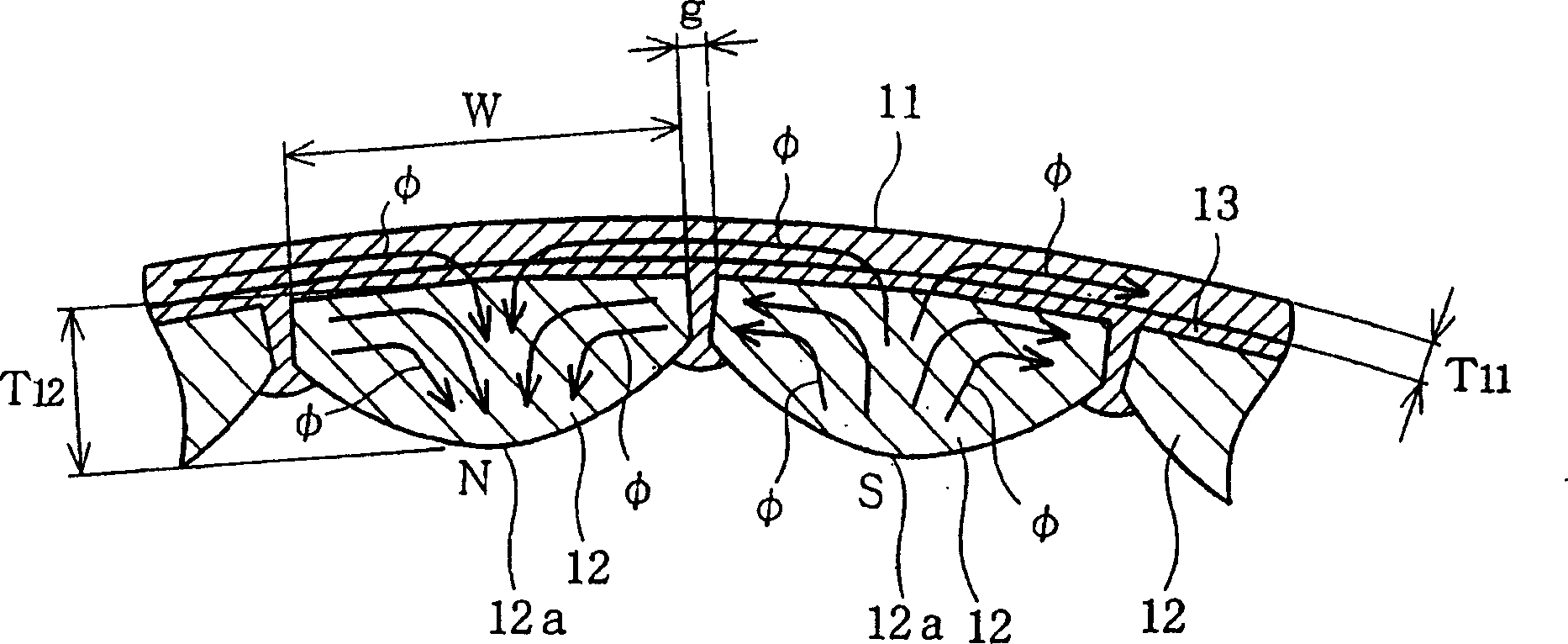

[0023] Below, refer to Figure 1 to Figure 3 A first embodiment of the present invention will be described.

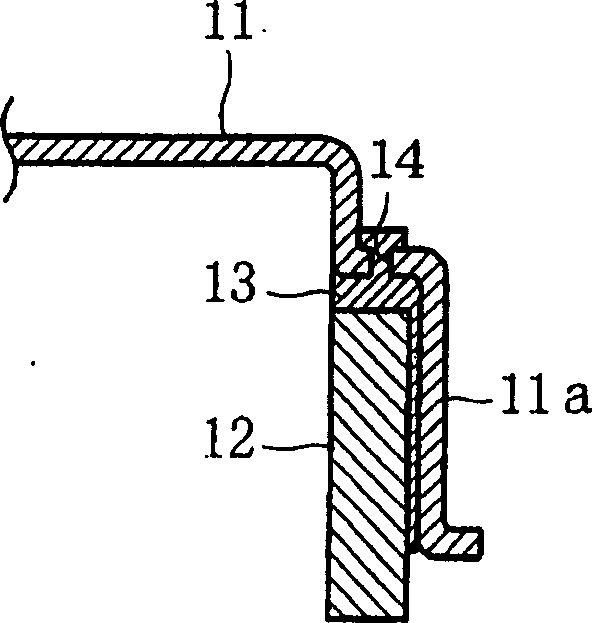

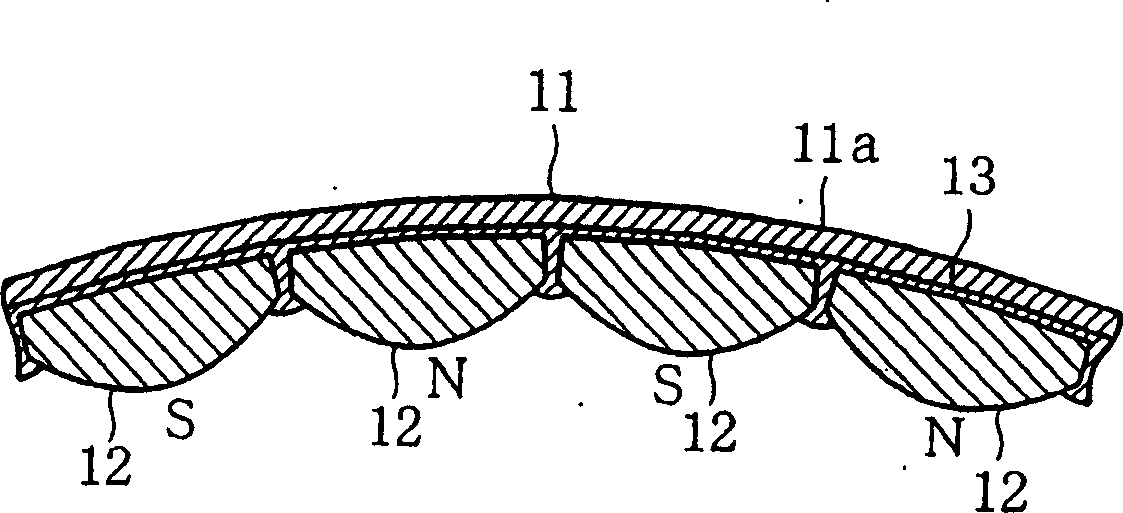

[0024] First, in figure 2 and image 3 The frame 11 is shown in the middle, and the frame 11 is formed into a flat cylindrical container shape with a cover by stamping a magnetic material such as a steel plate, and the peripheral side portion 11a is located outside the periphery of the stator (not shown). Thus, in this case the motor is of the outer rotor type with the rotor located outside the periphery of the stator.

[0025] On the stator side of the frame 11, that is, the inner circular surface of the peripheral side portion 11a ( figure 2 Middle is left, image 3 The middle is the bottom), and a plurality of permanent magnets 12 are arranged on the entire circumference, so that the polarities of N and S are opposite alternately. In addition, the permanent magnets 12 are fixed to the frame 11 (circumferential side portion 11 a ) by using a molding 13 of synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com