Novel magnesium alloy casting pipette and pipetting method thereof

A pipette and magnesium alloy technology, which is applied in casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the purity of magnesium alloy liquid, frequent tripping of heating wires, and difficulty in dredging and maintenance, so as to improve the purity , dredging and maintenance are convenient, and the effect of saving on blocked pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

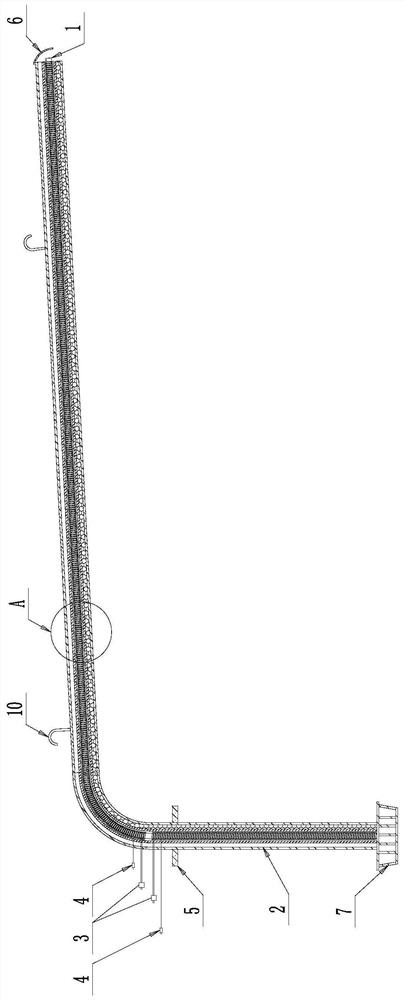

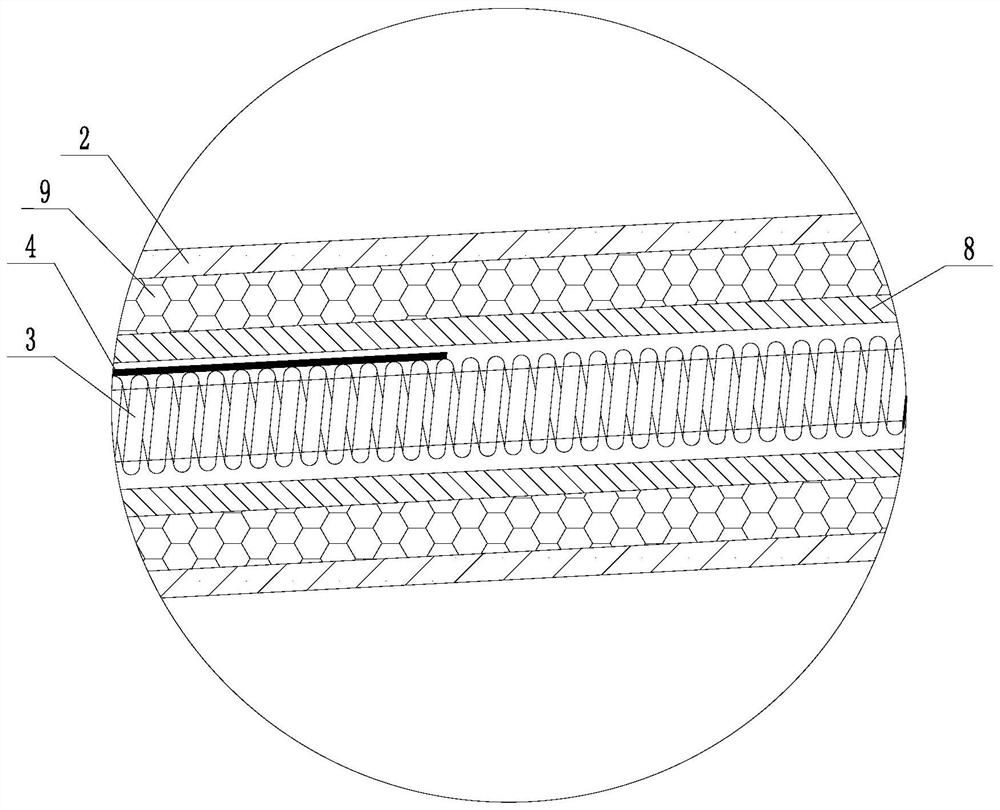

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] Such as figure 1 , 2 As shown, the novel magnesium alloy casting pipette described in the present invention includes: an inner layer guide tube 1; a casing 2 sleeved on the outside of the inner layer guide tube 1; The electric heating wire 3 on the outer wall; the thermocouple 4 used to detect the temperature of each electric heating wire 3; and the insulation belt arranged between the casing 2 and the electric heating wire 3; the casing 2 is fixed with a connecting flange 5, One end of the sleeve 2 is hinged to a liquid baffle 6 that covers the end of the inner draft tube. The slag retaining plate 7 is fixed at the bottom of the casing 2 . The insulation belt includes a metal insulation layer 8 arranged on the inside and a high-temperature aluminum silicate wool insulation layer 9 arranged on the outside. The casing 2 is provided with a hook 10 outside. The inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com