Power moment strengthening technique for fixing device for rotary cleaning element removing dirt inside pipe

A technology for fixing devices and cleaning parts, which is applied in the direction of cleaning rotating equipment, cleaning heat transfer devices, cleaning hollow objects, etc., and can solve the problems of affecting the rotation torque, large friction resistance torque, and insufficient reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of patent of the present invention is illustrated below in conjunction with accompanying drawing:

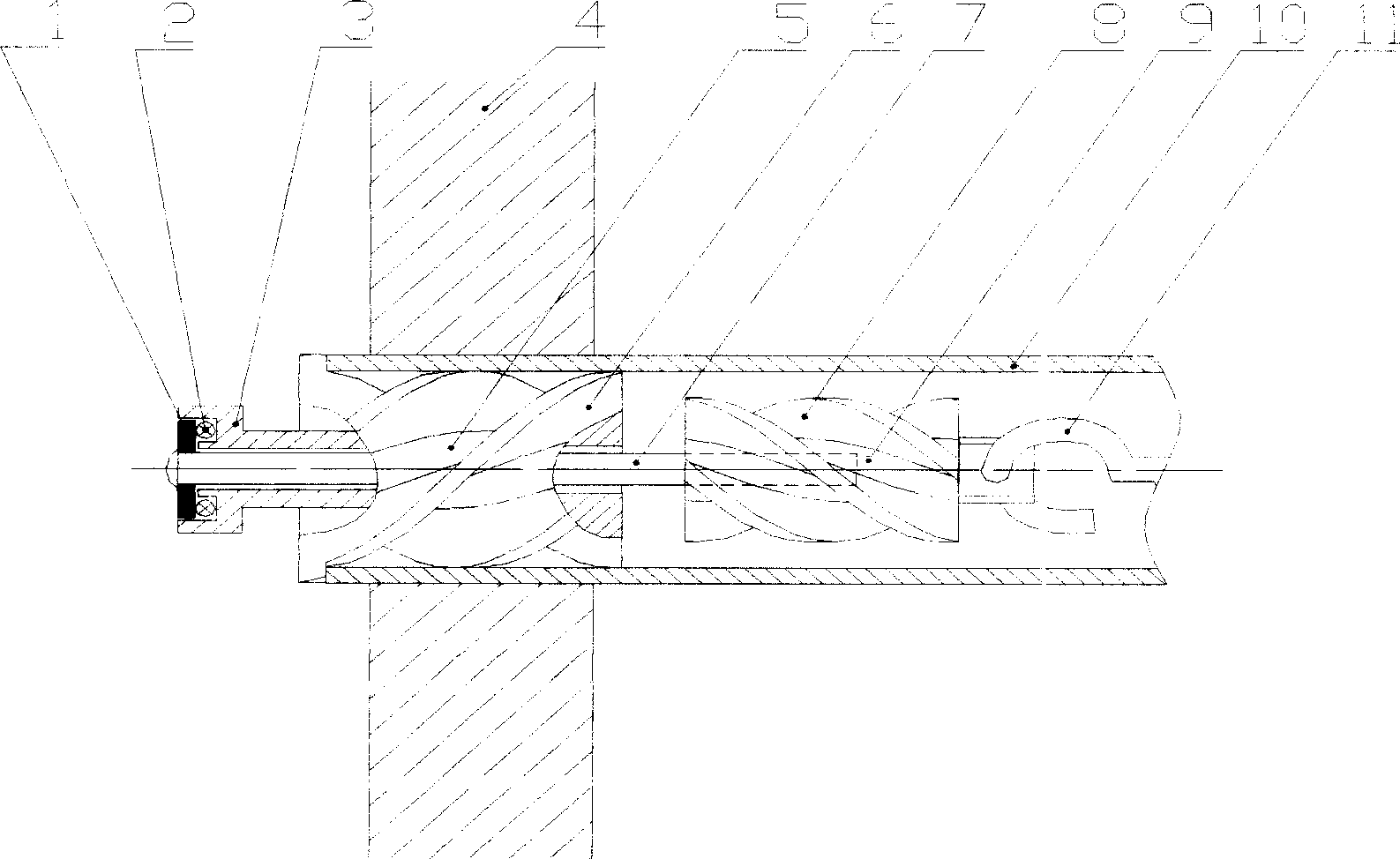

[0012] See figure 1 . The bearing bowl 3 and the reverse spiral flow channel 5 are of an integral structure, or may be of a split structure. The rotating shaft 7 is riveted or welded to the bearing cap 1 and fixed. The helical direction of the reverse helical channel 5 is opposite to the helical (or helical) direction of the rotating cleaning element 11 . The plastic power wheel 9 is integrally formed with the rotating shaft 7 during injection molding. The rotating shaft 7 is connected with a rotating cleaning element 11 . The diameters of the spiral guide fins 6 and the power wheel fins 8 are smaller than the inner diameter of the heat transfer tube 10 . During production, the bearing cover 1, the rolling ball 2, the bearing bowl 3, the reverse spiral flow channel 5, the rotating shaft 7 and the power wheel 9 can be assembled into an integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com