Electroluminescent lamp driver circuit with lamp discharge detection

A driving circuit and circuit technology, applied in the direction of electroluminescence light source, discharge lamp, electric lamp circuit layout, etc., can solve the problems of low brightness and EL lamp performance deterioration, and achieve high brightness and high performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

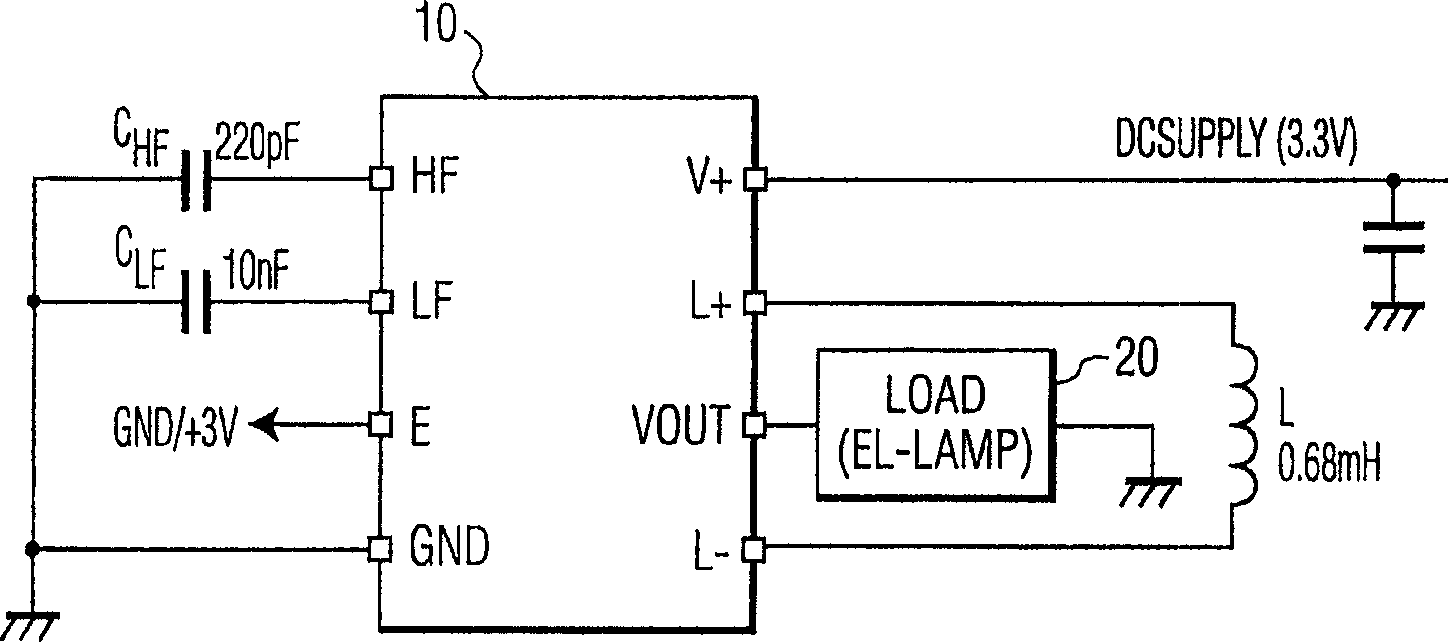

[0020] figure 1 An application of the driver circuit 10 according to one embodiment of the present invention is shown. As shown, the driver circuit 10 provides power to a load, such as an EL lamp 20 . The drive circuit 10 powers the EL lamp by repeatedly charging the inductor L with current from a low voltage DC power supply of about 3.3V and discharging the current to the capacitor of the EL lamp. With each cycle, the voltage of the lamp increases. After a sufficient charge cycle, the lamp will be discharged in a controlled manner and the lamp will be charged again with the opposite polarity. In this way, a symmetrical low frequency voltage is established across the lamp.

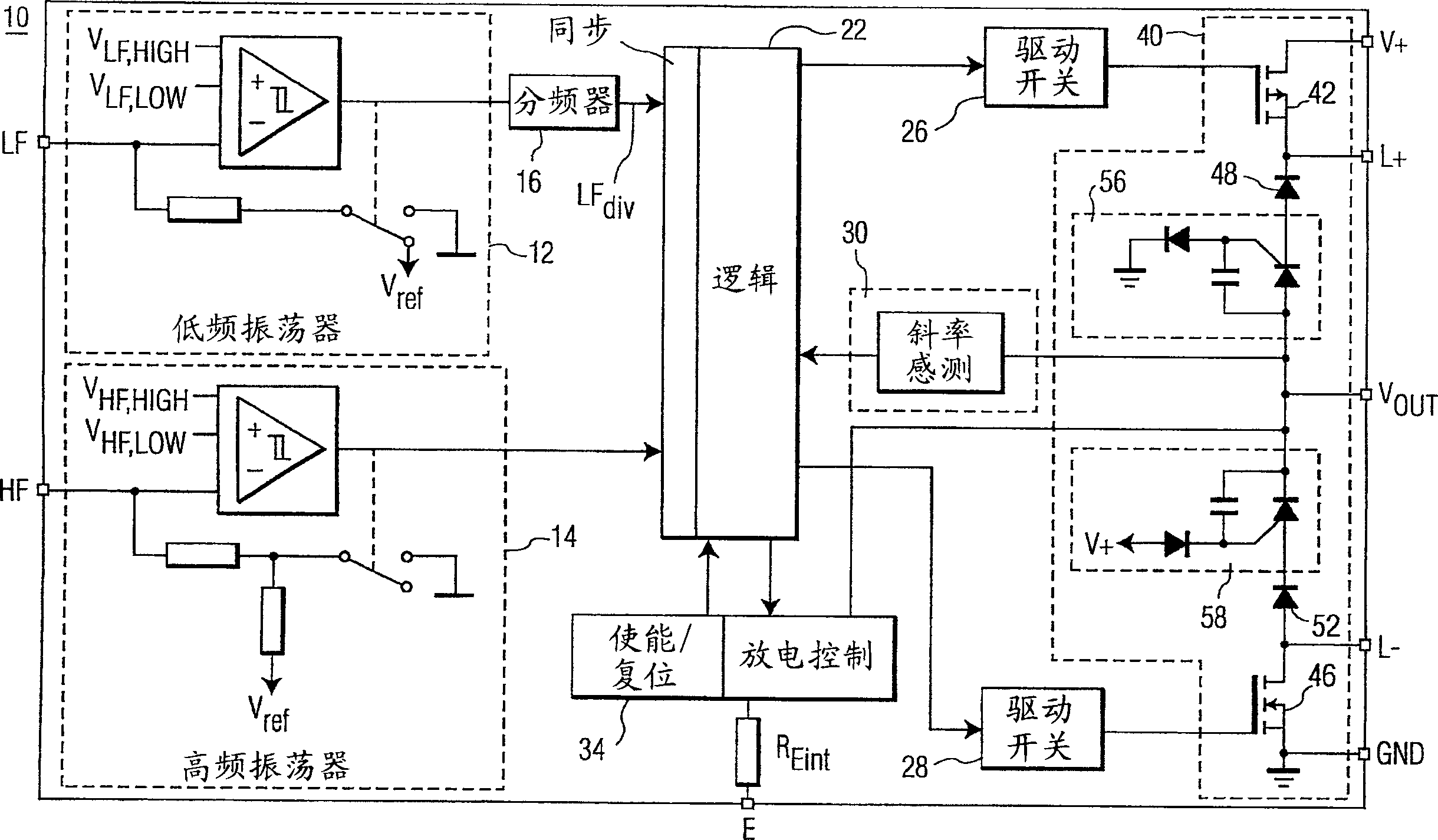

[0021] figure 2 A functional block diagram of the drive circuit 10 according to one embodiment of the present invention is shown. In the drive circuit 10, a low frequency (LF) oscillator 12 provides an LF signal to a controller 22 to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com