Rotation angle sensor

A technology of rotation angle and sensor, which is applied in the direction of converting sensor output, measuring angle, angle/taper measurement, etc. It can solve the problems of difficult compactness, high manufacturing cost, complex structure, etc., and achieve the effect of reducing size and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

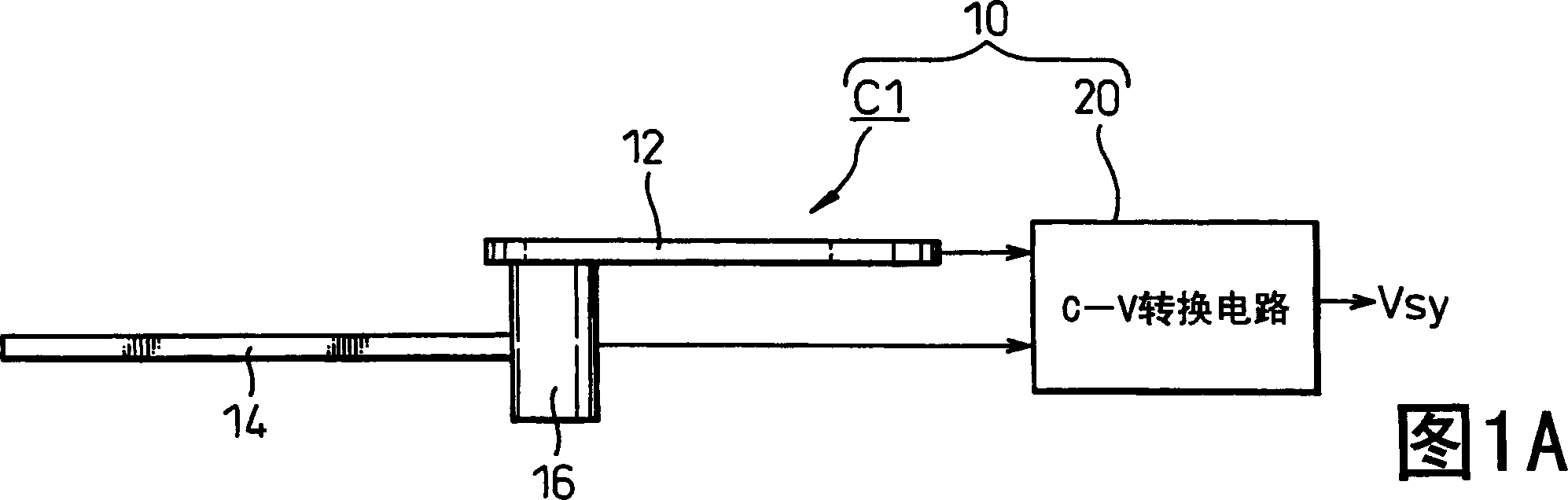

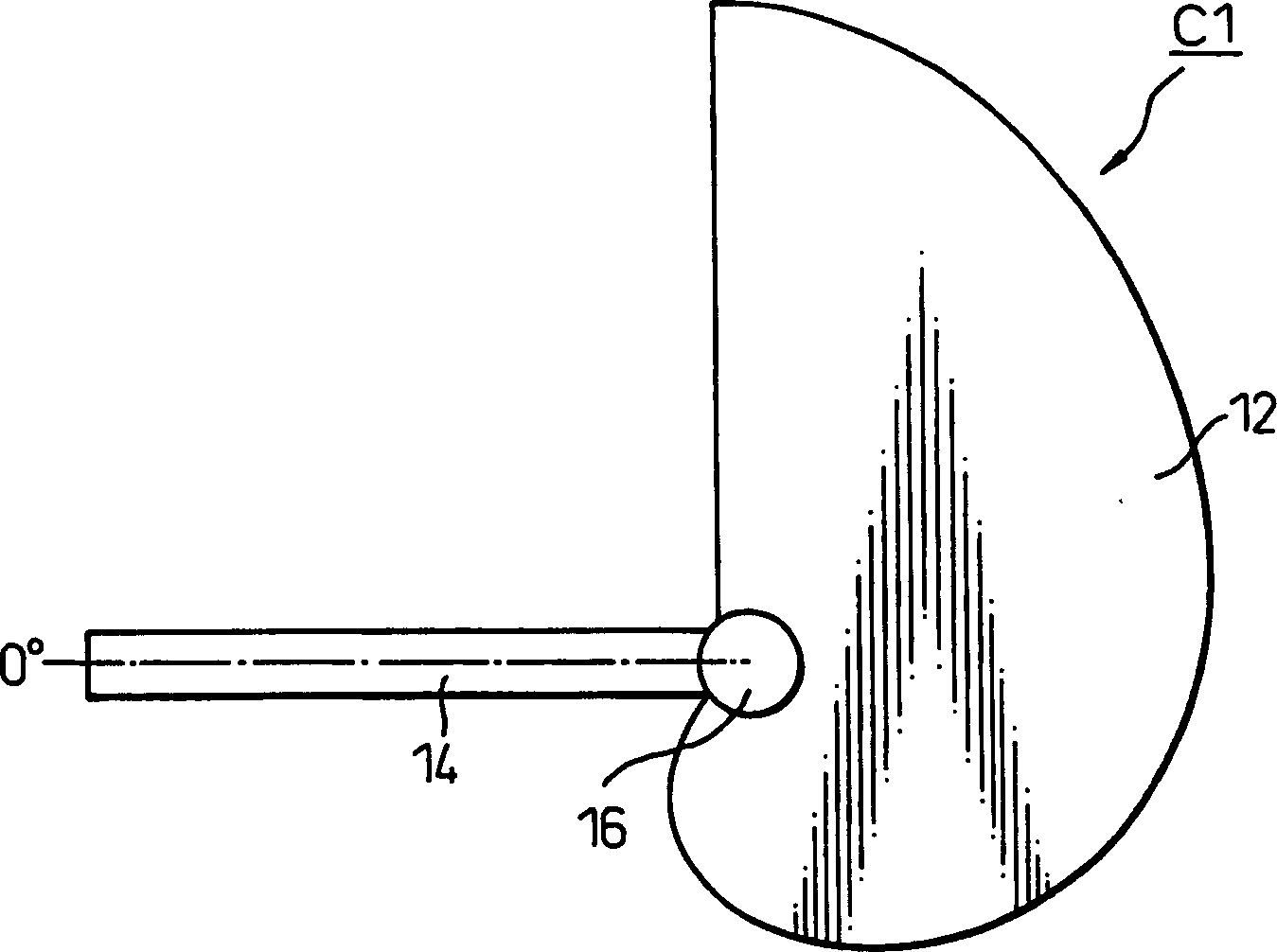

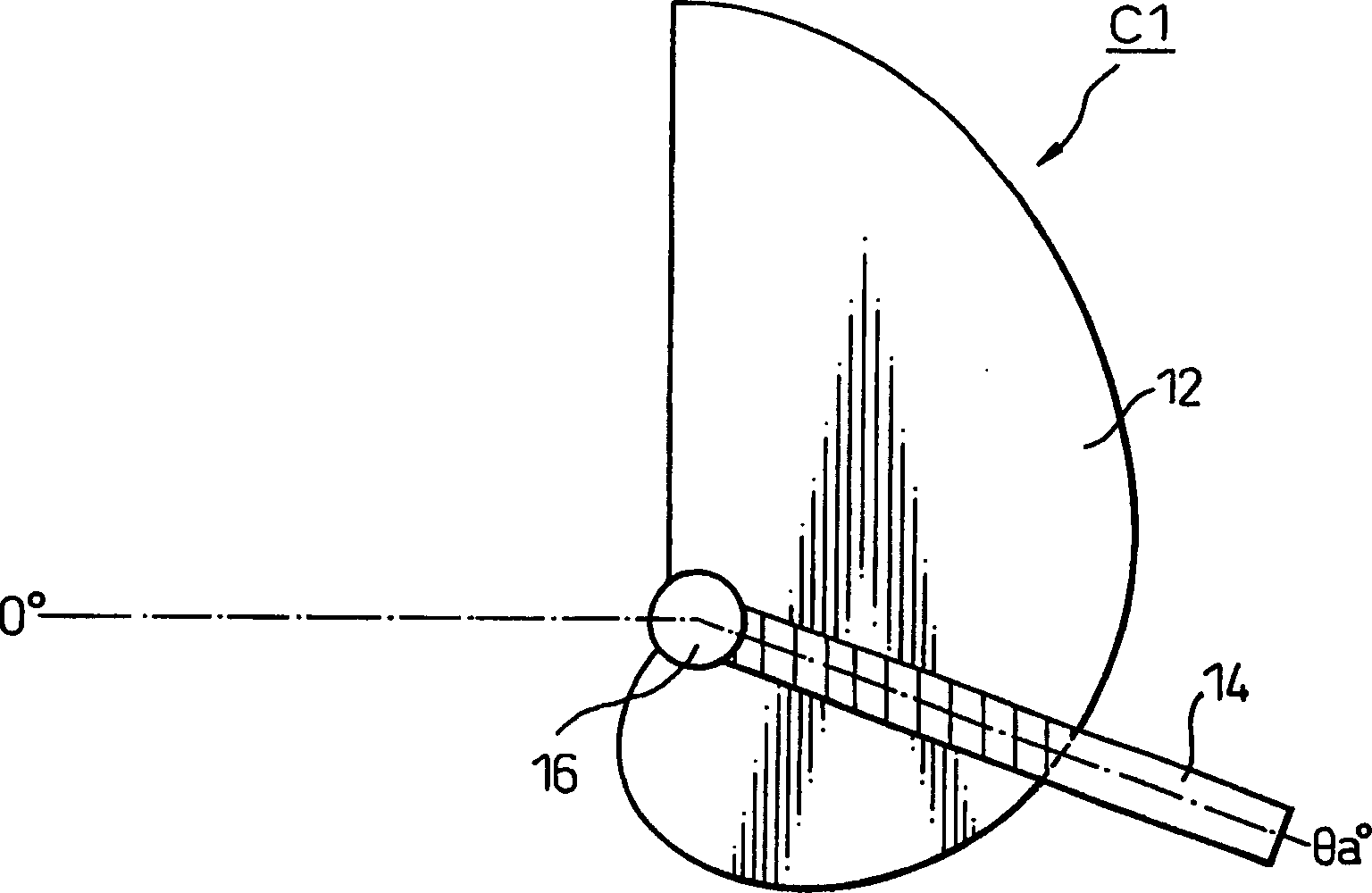

[0025] FIG. 1A is a plan view of a schematic configuration of a rotation angle sensor 10 of a first embodiment of the present invention. Figure 1B and Figure 2A and 2B is a front view of the rotation angle sensor 10 . The rotation angle sensor 10 includes a variable capacitor C1 and a C-V (capacitance-voltage) conversion circuit 20 .

[0026] Construction and Operation of Variable Capacitors

[0027] The variable capacitor C1 includes a fixed electrode 12 , a movable electrode 14 and a shaft 16 . Furthermore, the variable capacitor C1 is fabricated using a micromachining technique. From Figure 1B and Figure 2A and 2B The vertical and horizontal external dimensions of the variable capacitor C1 are both less than 1 mm when viewed from the front view direction shown in .

[0028] The planar fixed electrode 12 has a cylindrical axis 16 rotatable in a direction perpendicular to its surface. An elongated movable electrode 14 is fastened on this shaft 16 . Also, the mov...

no. 2 example

[0056] 6A is a plan view of a schematic configuration of a rotation angle sensor 30 of the second embodiment, and Figure 6B is a front view of the rotation angle sensor 30 . The rotation angle sensor 30 differs from the rotation angle sensor 10 of the first embodiment only in the planar shape of the fixed electrode 22 of the variable capacitor C1.

[0057] Figure 7 is a graph of the relationship between the rotation angle of the movable electrode 14 and the electrostatic capacitance between the electrodes 12 and 14 in the second embodiment. The planar shape of the fixed electrode 22 is set so that the electrostatic capacity between the electrodes 12 and 14 (the area of the overlapped portion of the electrodes 12 and 14) is determined according to Figure 7 The characteristics shown in can vary.

[0058] Thus, in the second embodiment, by appropriately setting the planar shape of the fixed electrode 22, the electrostatic capacitance between the electrodes 12 and 14 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com