Method for producing a device defining a volume for retaining a fluid or a sensitive material

一种感光材料、流体的技术,应用在制造例如电光显示元件或电化学光电元件的装置领域,能够解决精确度不再足够、体积庞大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

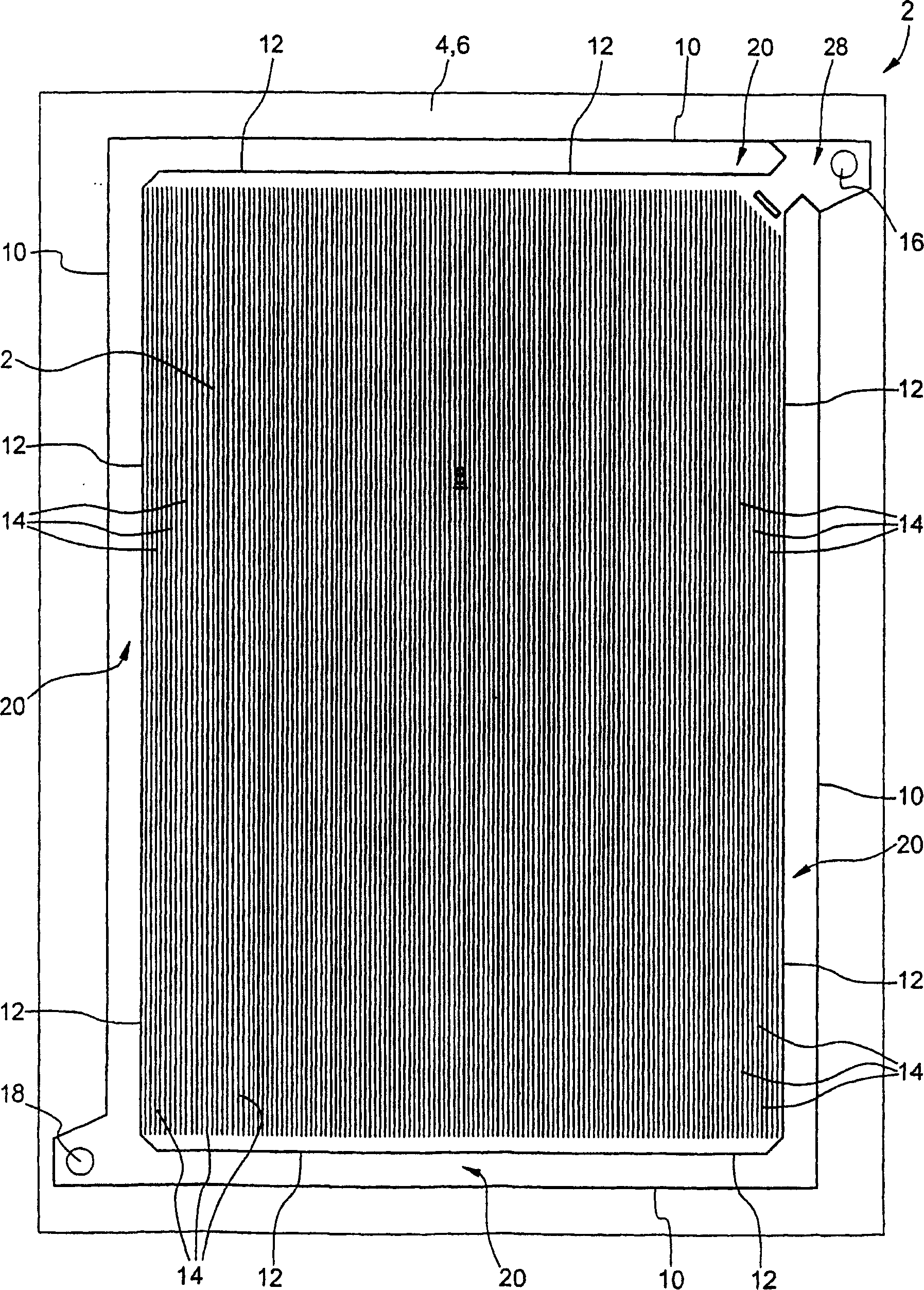

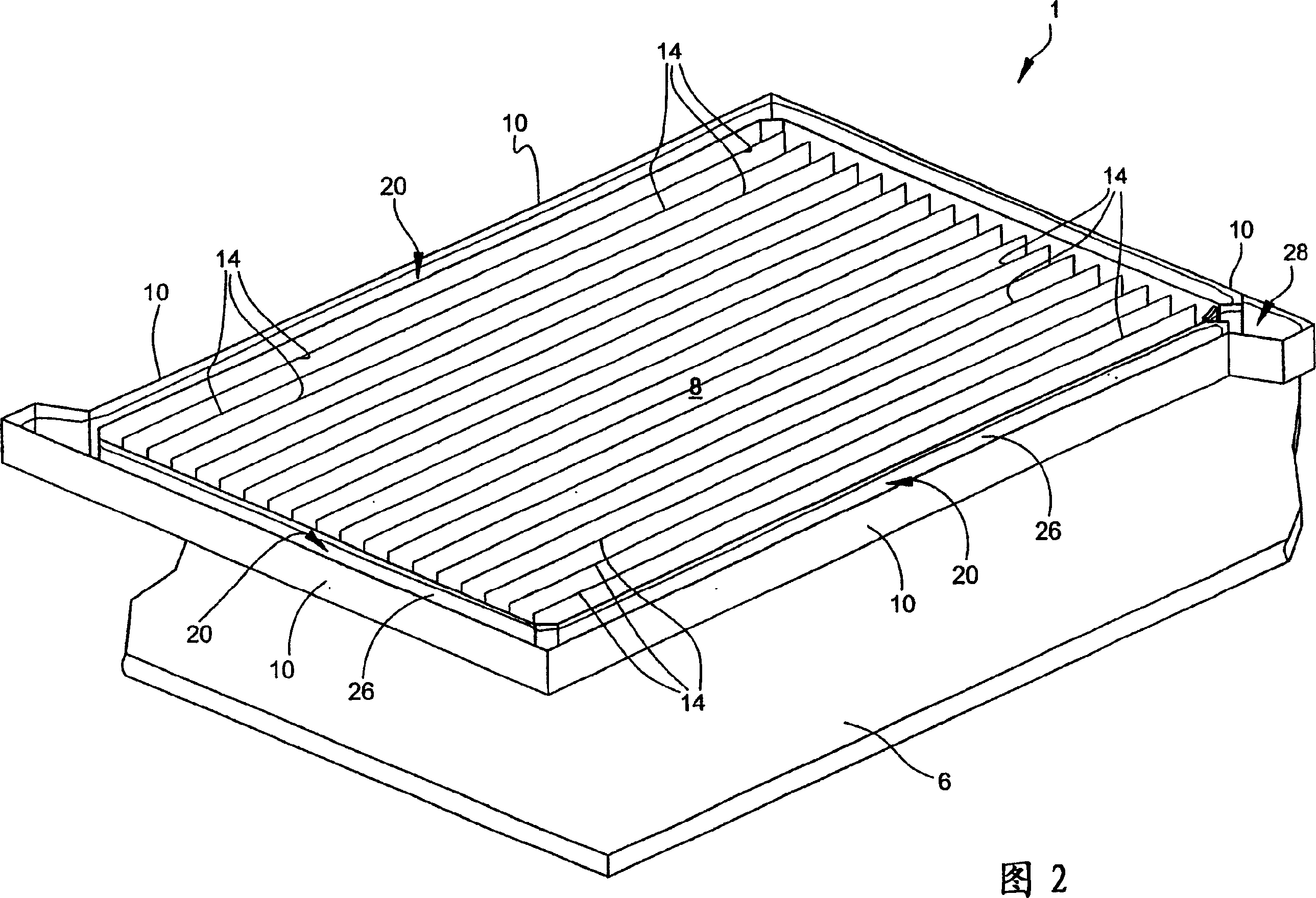

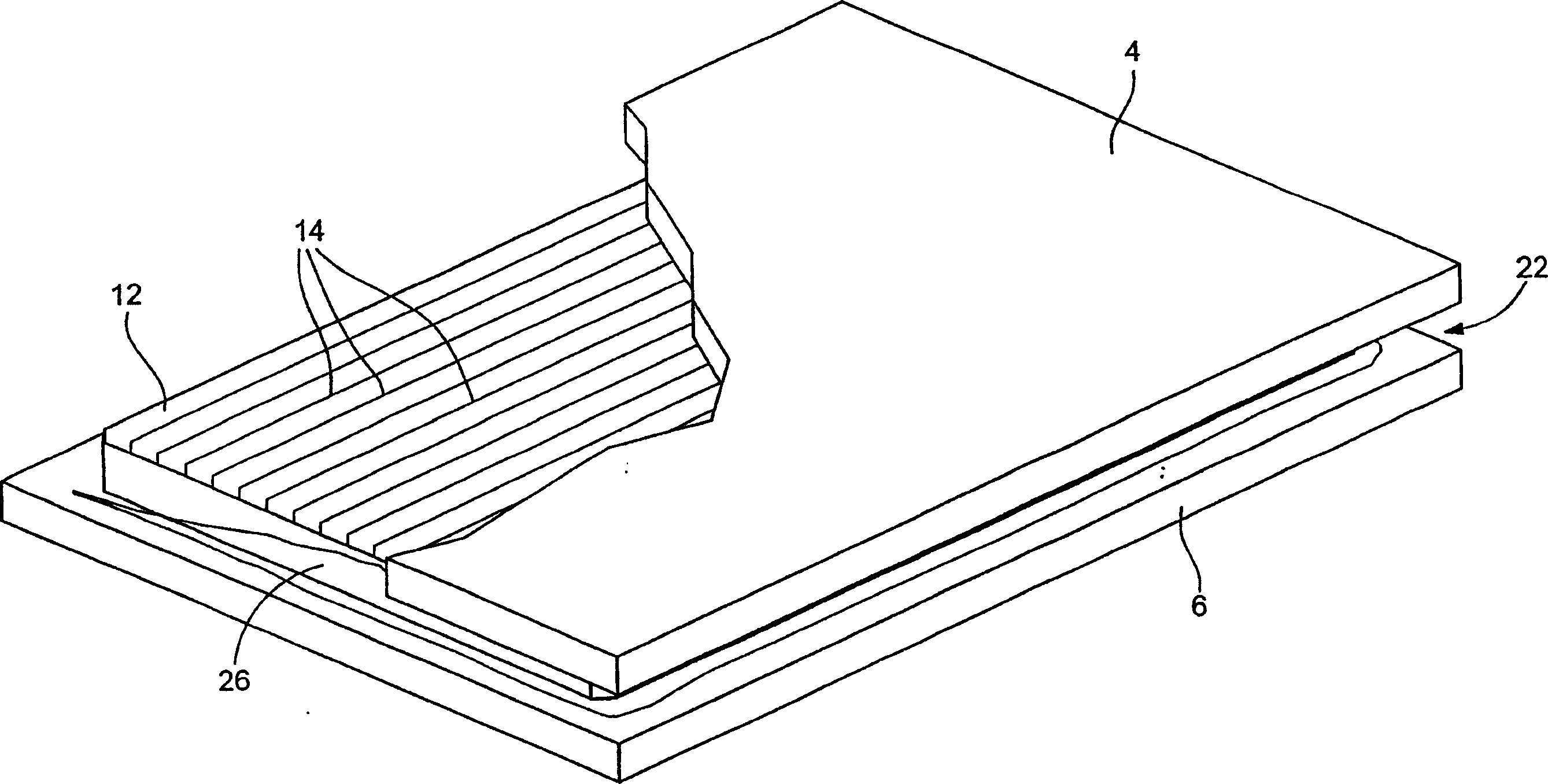

[0050] The present invention proceeds from the general inventive idea by proposing a new method of manufacturing a sealing frame which usually joins the bottom and top substrates of a display element, in particular a liquid crystal element, or an electrochemical optoelectronic element. According to the new method, the technique of depositing the sealing frame by screen printing, which usually takes place in the pre-component manufacturing stage and generates mechanical stresses that are detrimental to the already deposited adjacent component structures, is replaced by photolithography. The technique does not create any special stresses and in particular enables the simultaneous formation of the liner and the filling channel receiving the fluid sealing material which, after curing, forms the desired sealing frame. The invention also provides a new technique for assembling and sealing substrates of fluidic microsystems.

[0051] The invention will be described in connection with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com