Yarn package carrier for dyeing machines

A dyeing machine and yarn hanging technology, which is applied in liquid/gas/steam yarn/filament processing, liquid/gas/steam processing of a certain length of textile materials, and processing of textile material carriers, etc., which can solve the problem of staff injury and time-consuming , manual loading is impractical and other issues, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

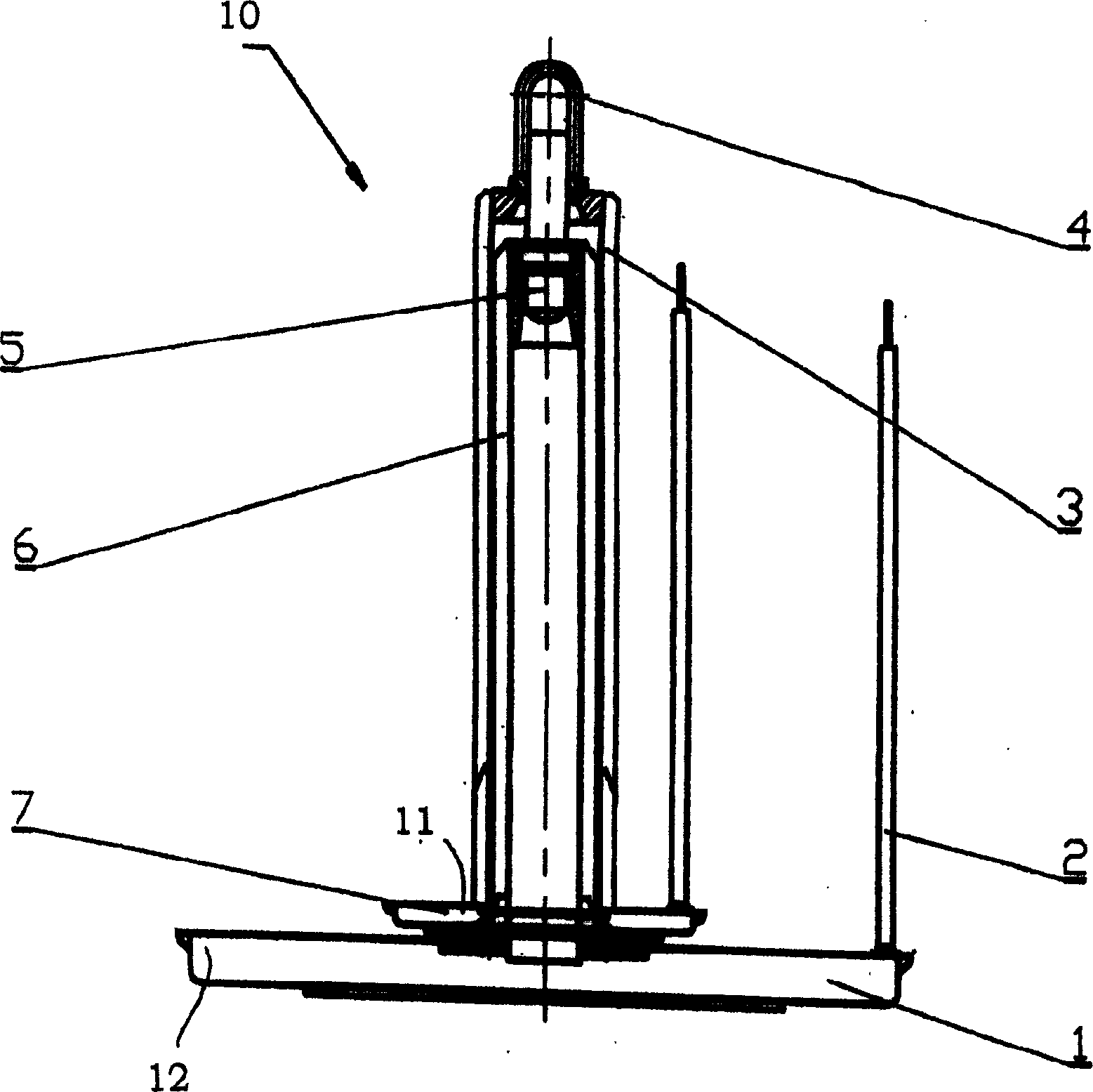

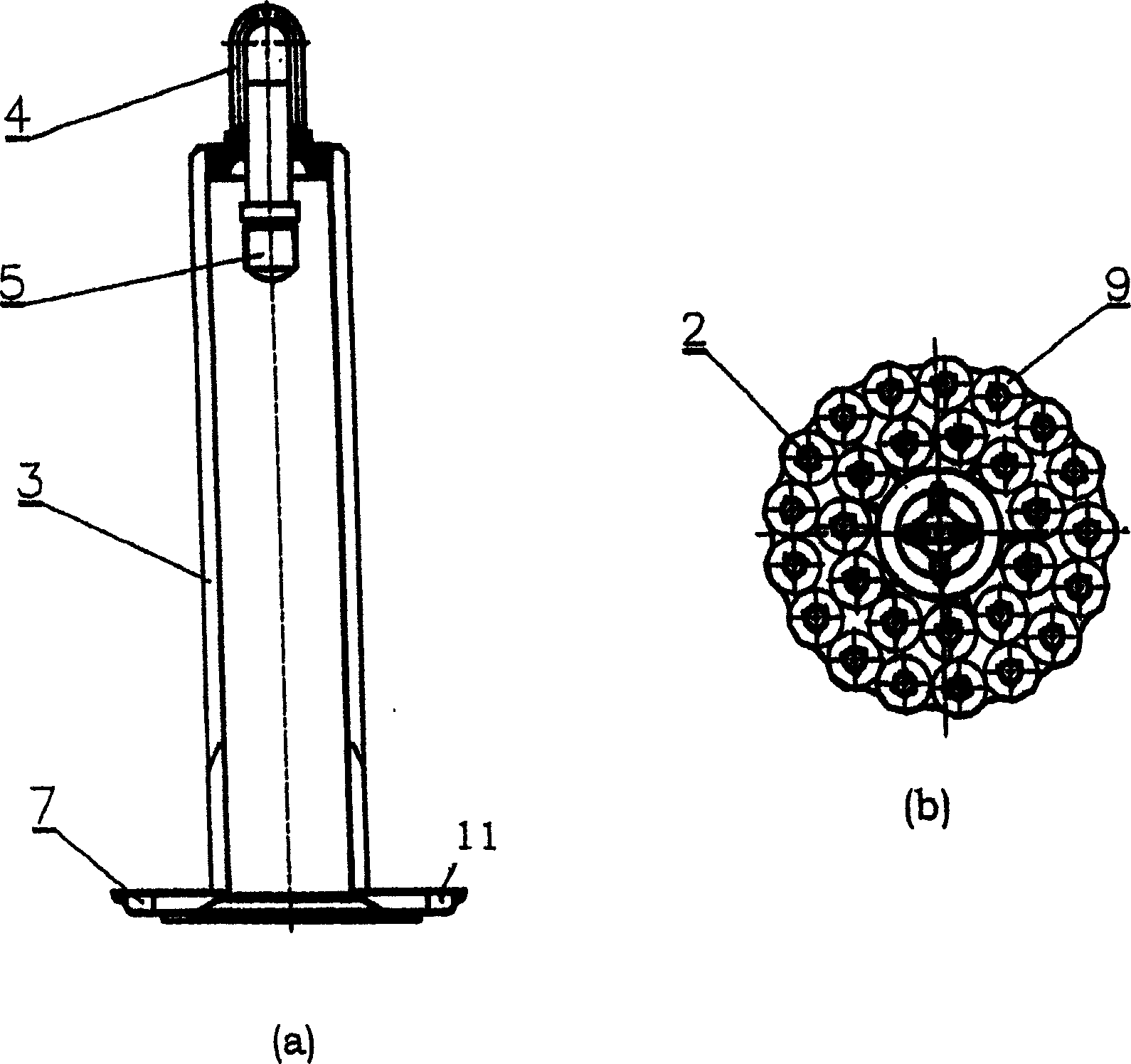

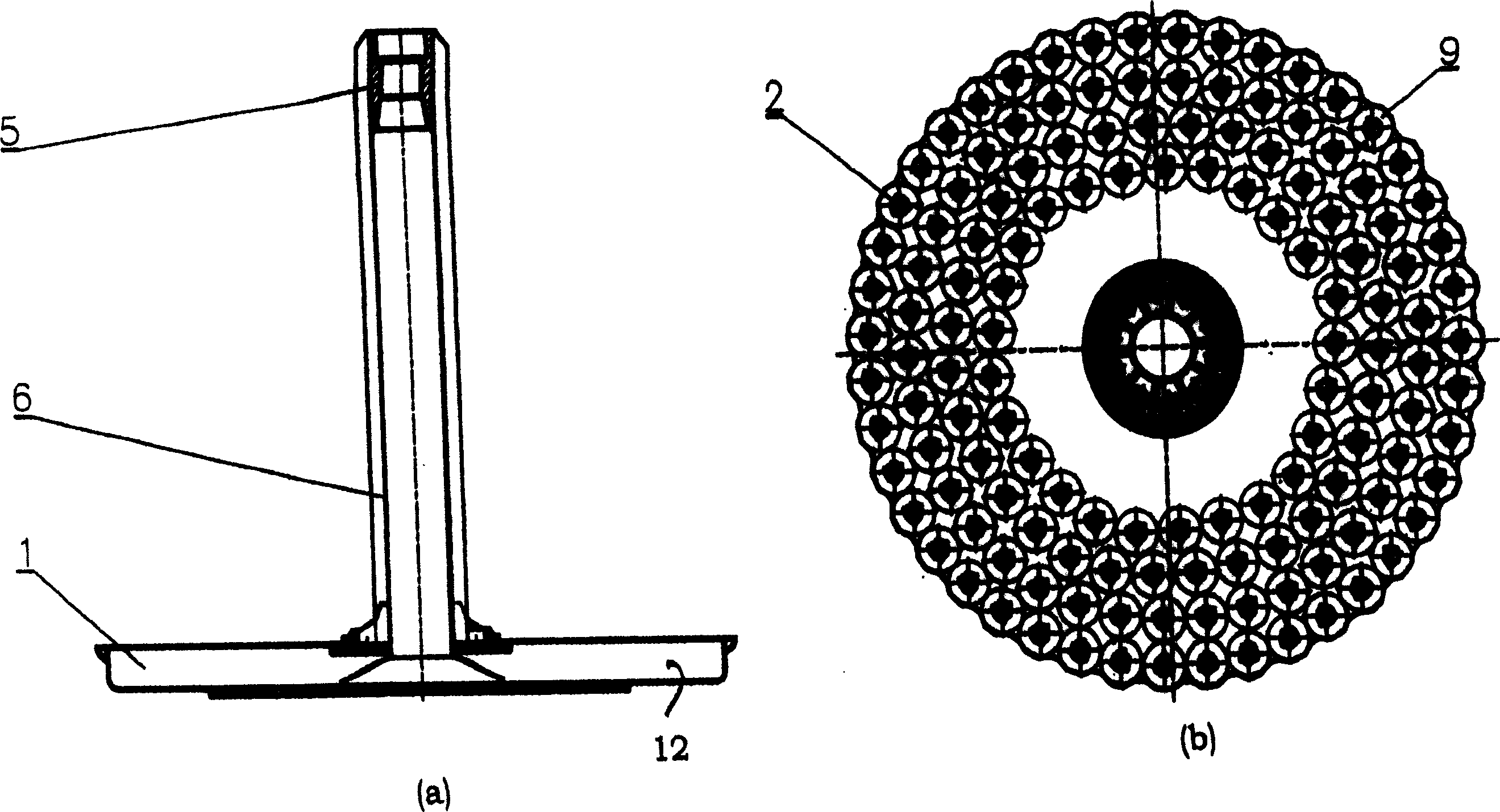

[0031] Embodiments of the present invention aim at that the creel 10 can carry a batch of cheeses 9 in a single step (such as figure 2 a, 3b shown) into a cheese dyeing machine (not shown).

[0032] In the illustrated embodiment, figure 1 The hanging creel includes an inner carrier assembly 7 which is concentrically arranged in an outer carrier assembly 1 . The creel 10 includes inner and outer carrier assemblies 7, 1, each having a substantially circular cross-section, of course, any suitable cross-sectional shape may be used by those skilled in the art.

[0033] figure 1 The outer carrier assembly 1 is shown comprising a cylindrical chamber with a central section without a mandrel 2 whereby the inner carrier assembly 7 can be accommodated.

[0034] Each inner and outer carrier assembly 7, 1 includes a base 11, 12 respectively, and is used to support a plurality of mandrels 2 and central columns 3, 6 respectively.

[0035] Each inner carrier 7 and outer carrier 1 contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com