Processed tomato products and process for preparing the same

A tomato and product technology, applied in food preparation, botanical equipment and methods, plant products, etc., can solve the problems of unreported and blocked commercial use, and achieve the effect of improving taste and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1: Breeding and Screening

[0078] As starting material, a cross between a homozygous maturation-suppressing mutant (thought to be alc; see Example 5 for validation) and a homozygous old golden-crimson (ogc) mutant was obtained from Ohio State University, USA (The accession number is 96-9422-400). This F1 heterozygous alc / ogc population was then selfed and mono-plants were selected for the phenotypic traits of both inhibition of fruit ripening (homozygous alc) and golden flower color (homozygous ogc). Seeds from selected plants were then backcrossed to indoor breeding lines to generate stable double homozygous plants for evaluation of fruit and processed tomato product characteristics.

Embodiment 2

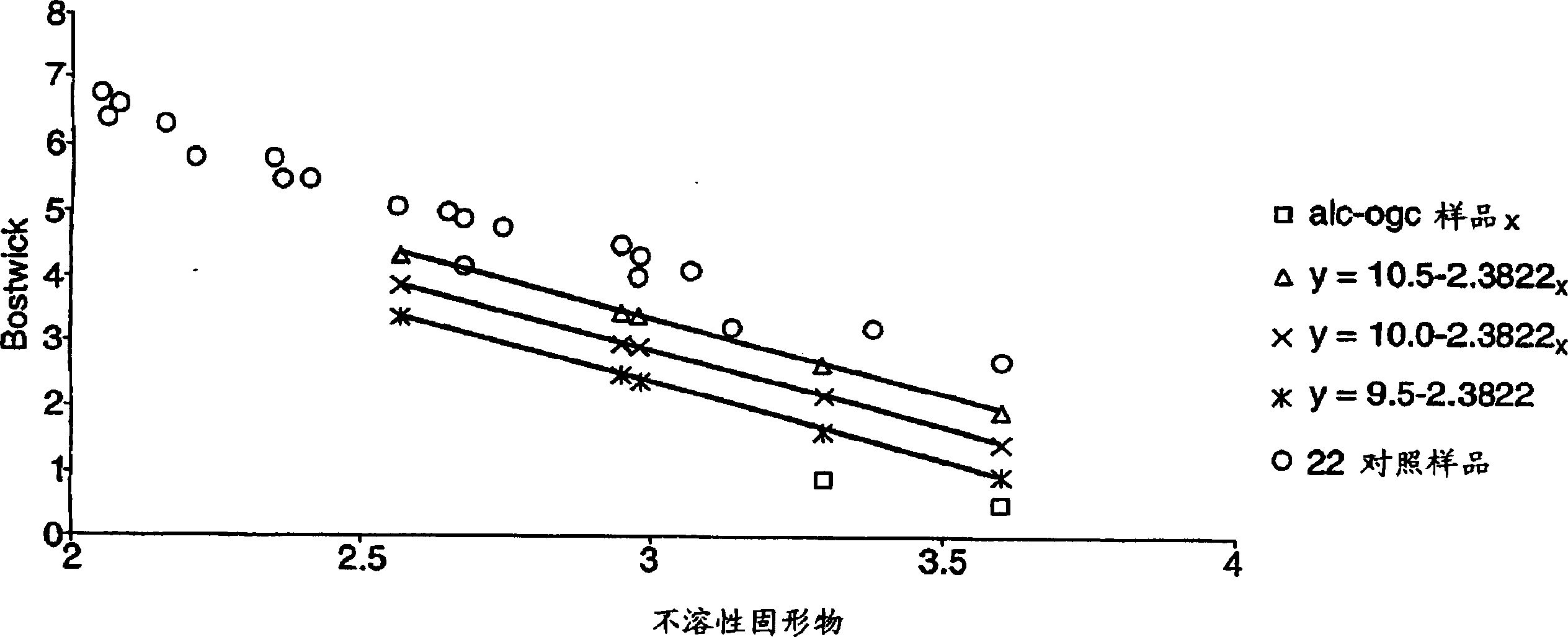

[0079] Example 2: Bostwick with insoluble solids: 22 conventional sauces (control) and sauces according to the invention

[0080] The percentage of insoluble solids was determined and Bostwick values determined (all at 12° Brix) in 22 factory or commercially available hot or cold crushed tomato pastes. The Bostwick value (average of the different determinations for each sauce) is then plotted against the percentage of insoluble solids. Hot crushed paste is a commercially available product, or prepared in one's own factory using the following method: Tomatoes are crushed in such a way as to minimize air entrainment and rapidly heated to >85°C, typically by means of a steam coil with touch. The juice is then extracted and evaporated to 24°-31° Brix typically by a 2 or 3 stage process. For the assay, the samples were diluted to 12° Brix.

[0081] Cold crushed sauce is a commercial product that is typically prepared by crushing tomatoes at a temperature below 85°C in a manner...

Embodiment 3

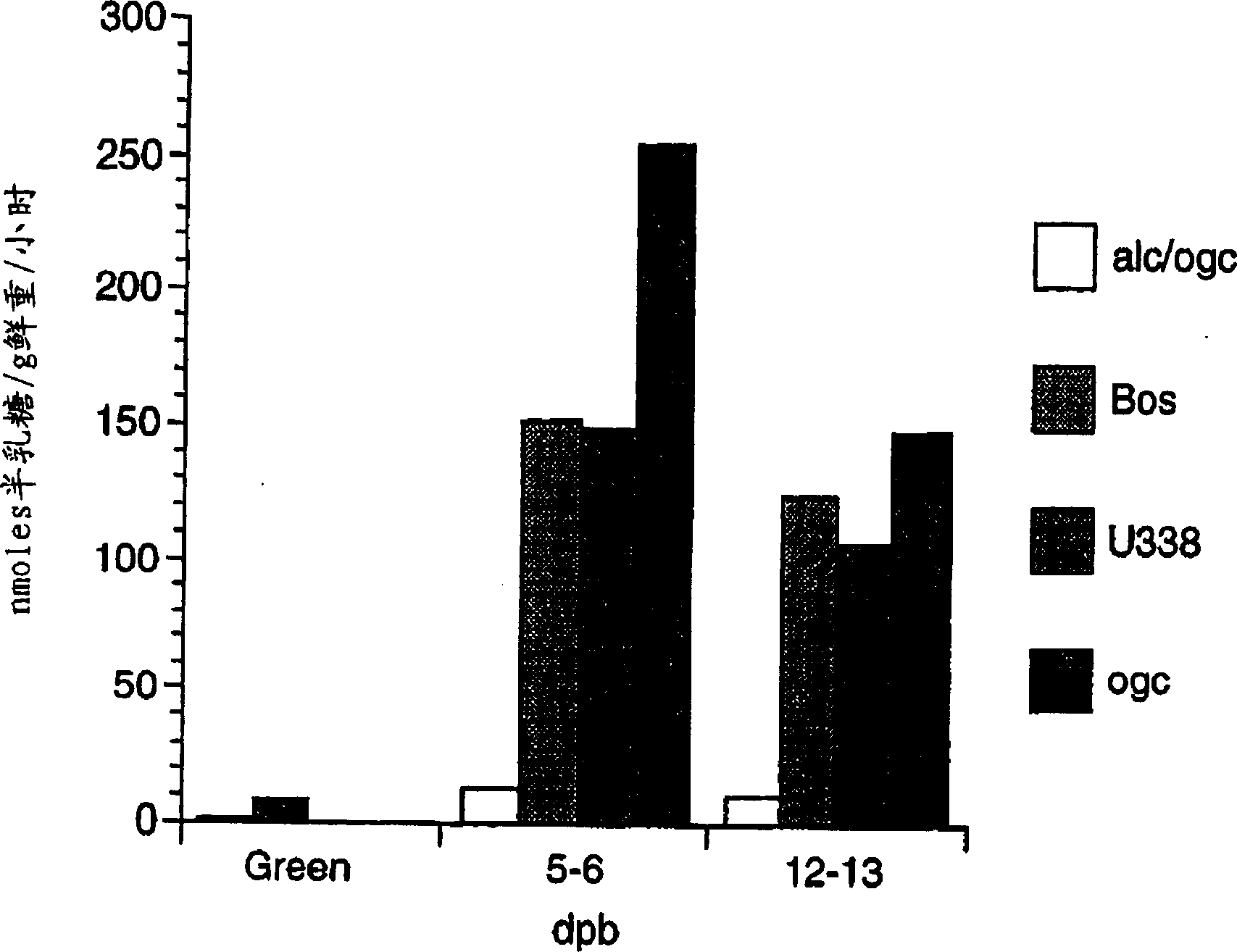

[0096] Example 3: Exogalactanase activity

[0097] The exogalactanase activity of four types of tomato was measured at three stages of ripening: the green stage (ie just before the break point), 5-6 days after break, and 12-13 days after break. The four tomato groups are: the tomato of Example 1, which is considered homozygous for alc and homozygous for ogc; Bos 3155 (commercially available); U338 (internal breeding line with regular ripeness and color); and homozygous ogc (with a regular mature internal breeding line).

[0098] Exogalactanase activity can be expressed as nanomoles of galactose per gram of fresh weight (fwt) per hour, which can be converted. Use the following protocol to determine the conversion of galactose.

[0099] Extract preparation

[0100]Samples of tomato peel were obtained from cryopreservation and placed in 50 ml Falcon plastic tubes containing PVPP (1% w / v buffer). Then a 1:1.5 (w:v) 0.2M sodium phosphate buffer (pH 7.5) was added. Leave it at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com