Substrate for a perpendicular magnetic recording medium and a perpendicular magnetic recording medium using the substrate

A technology of perpendicular magnetic recording and disk substrate, applied in the direction of the base layer of the recording layer, magnetic recording, magnetic recording layer, etc., can solve the problems of high-density recording, low production cost, etc., achieve good recording and reproduction performance, and cheap The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

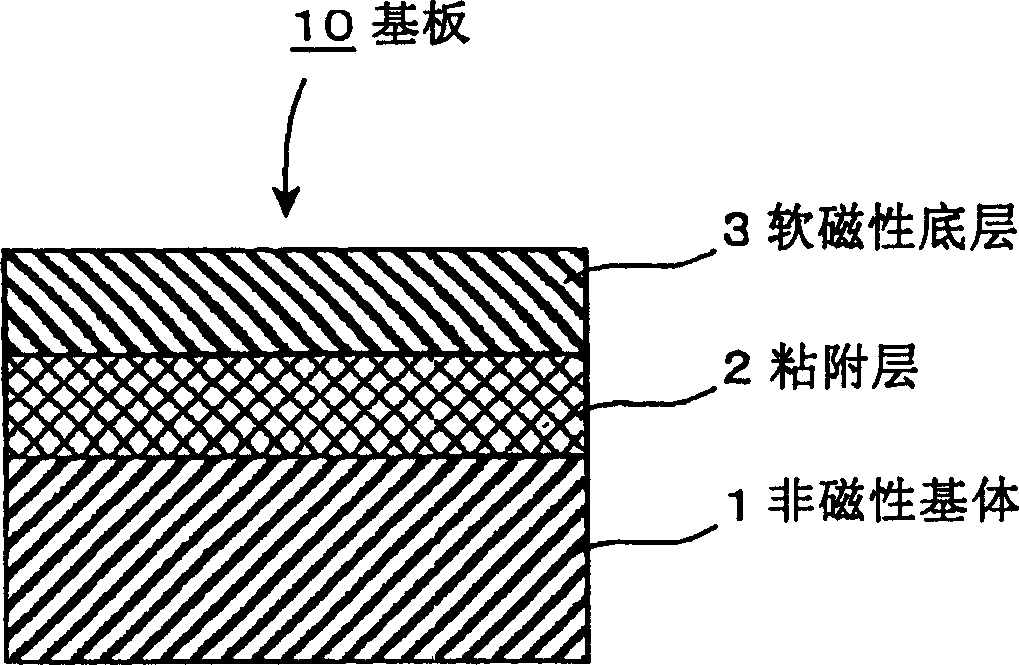

[0105] manufacture figure 1 Substrate shown

[0106] A disk-shaped Al-Mg alloy plate with a nominal diameter of 3.5 inches was used as figure 1 The non-magnetic substrate in 1. The substrate surface is cleaned by alkaline cleaning and acid etching and zincated (zinc immersion plating) as a starting reaction layer for electroless Ni-P coating. Then, use a commercially available electroless Ni-P plating solution (NIMUDENHDX manufactured by C.Uyemura & Co., Ltd.) for hard disk substrates to be controlled under the following conditions—the nickel concentration is 6.0 ± 0.1g / L, the pH value is 4.5±0.1, and the liquid temperature is 92±1° C.—a non-magnetic Ni-P alloy adhesion layer 2 with a thickness ranging from 0-10 μm is formed in the plating bath. The average phosphorus concentration in the non-magnetic Ni-P coating is 20 at%.

[0107] Subsequently, a soft magnetic underlayer 3 of CoNiP alloy with a thickness ranging from 0.5 to 10 μm was formed using the plating bath (1) s...

Embodiment 2

[0129] Manufactured in the same manner as in Example 1 figure 1 In the substrate 10 for perpendicular magnetic recording media, only the thickness of the adhesive layer 2 is 5.0 μm, the thickness of the soft magnetic underlayer 3 is 1.5 μm, and through the range shown in the plating bath (2) of Table 3 The conditions of the plating bath were changed so that the average phosphorus concentration in the soft magnetic underlayer 3 varied between 3 at % and 25 at %. The average cobalt concentration in the soft magnetic underlayer 3 is 67 at % to 72 at % in the ratio of the number of cobalt and nickel atoms excluding phosphorus. When the phosphorus concentration is lower than 3 at%, it is found that the plating bath is very unstable and cannot be mass-produced.

[0130] nickel sulfate

7-12g / L

cobalt sulfate

7-12g / L

sodium hypophosphite

10-30g / L

Sodium citrate

20-80g / L

sodium tartrate

0-150g / L

sodium acetate

0-80g / ...

Embodiment 3

[0136] Manufactured in the same manner as in Example 1 figure 1 In the substrate 10 for perpendicular magnetic recording media, only the thickness of the adhesive layer 2 is 5.0 μm, the thickness of the soft magnetic underlayer is 1.5 μm, and by changing the range shown in the plating bath (3) of Table 4 The conditions of the plating bath were varied such that the average cobalt concentration in the soft magnetic underlayer 3 was in the range of 18.8 at% to 90.9 at% in the number of atoms of cobalt and nickel other than phosphorus. The average phosphorus concentration in the soft magnetic underlayer is 10 at% to 20 at%.

[0137] nickel sulfate

6-18g / L

cobalt sulfate

2-14g / L

sodium hypophosphite

10-20g / L

Sodium citrate

60g / L

pH

6.5±0.2 to 8±0.2 (through NaOH and H 2 SO 4

Adjustment)

liquid temperature

80±2℃

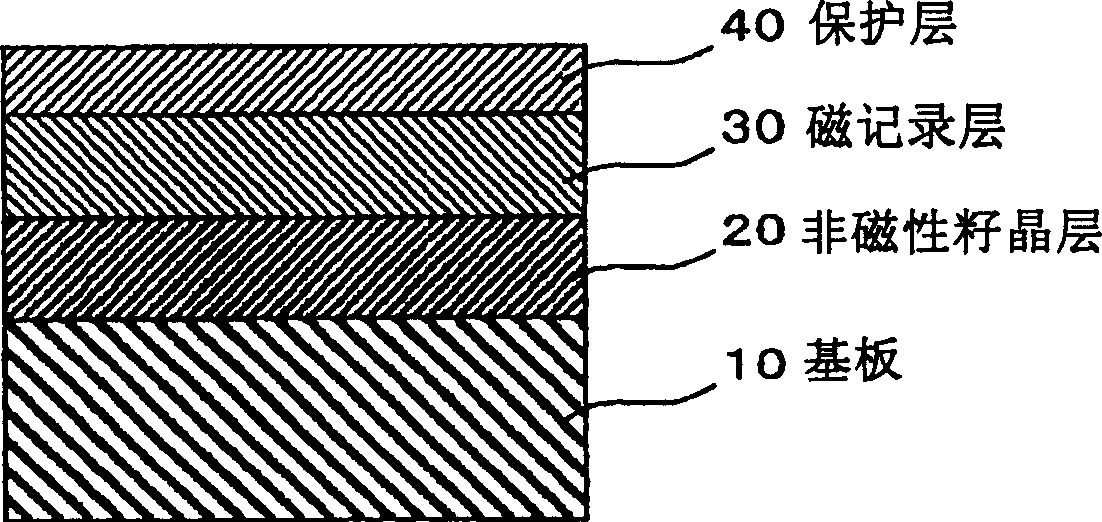

[0138] Then, manufacture as embodiment 1 figure 2 perpendicular magnetic recordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com