Driving circuit of liquid-crystal displaying device

A liquid crystal display and driving circuit technology, which is applied in static indicators, instruments, etc., can solve the problem that the common voltage Vcom voltage drop phenomenon cannot be specifically improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features, and advantages of the present invention more comprehensible, preferred embodiments are specifically cited below, together with the accompanying drawings, and described in detail as follows.

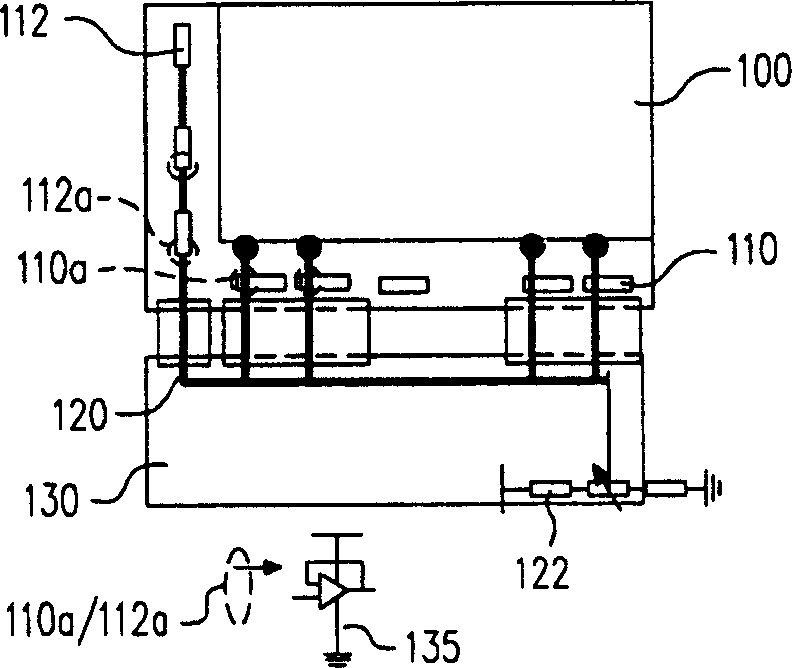

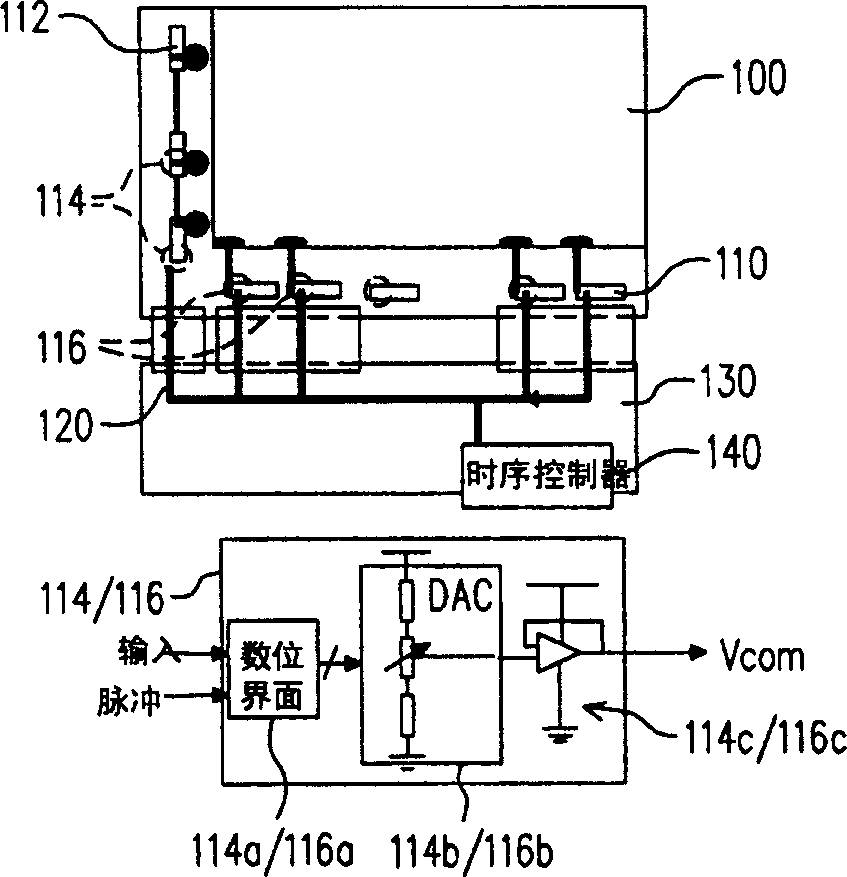

[0025] figure 2 It is a schematic diagram of the layout of the LCD driving circuit and the common voltage circuit drawn according to the first embodiment of the present invention. figure 2 The structure is figure 1 An improved version of the existing structure. Such as figure 2 as shown, figure 2 The structure is to configure the buffer originally on the circuit board 130 into each source driver 110 and gate driver 112, for example figure 2 Locations 112a and 110a are indicated. The layout of the common voltage line 120 extends from the circuit board 130 to each source driver 110 and reaches the ITO layer (not shown) in the panel 100 . In addition, the common voltage line 120 is also extended to connect each gate driver 112 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com