Wedge loading mechanism for traction drives

A traveling wheel and driver technology, which is applied in mechanical equipment, transmission devices, friction transmission devices, etc., can solve the problems of driving design imposition of traveling wheels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

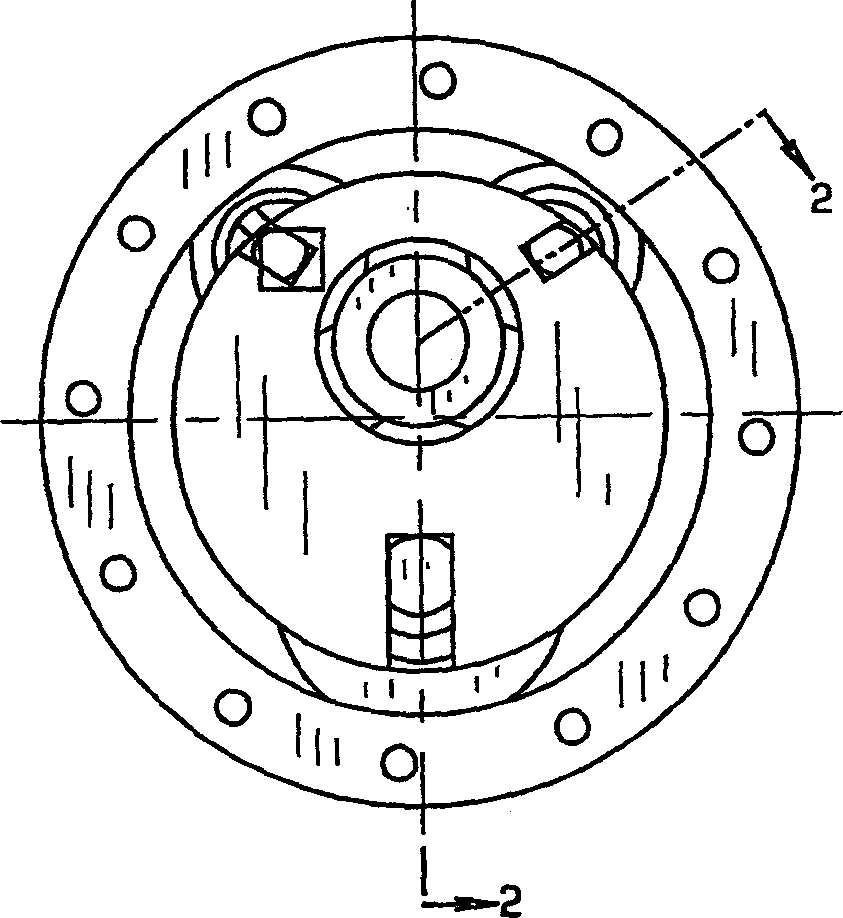

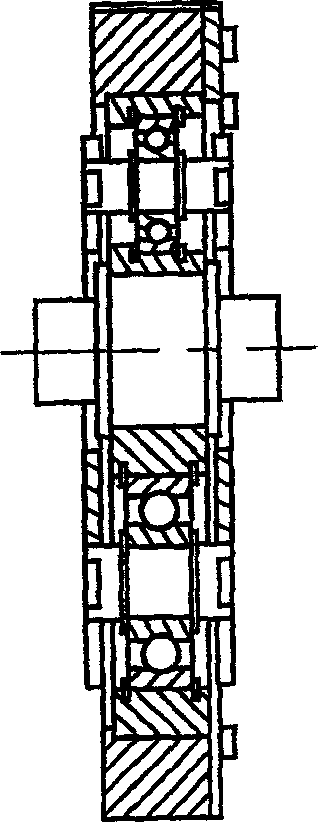

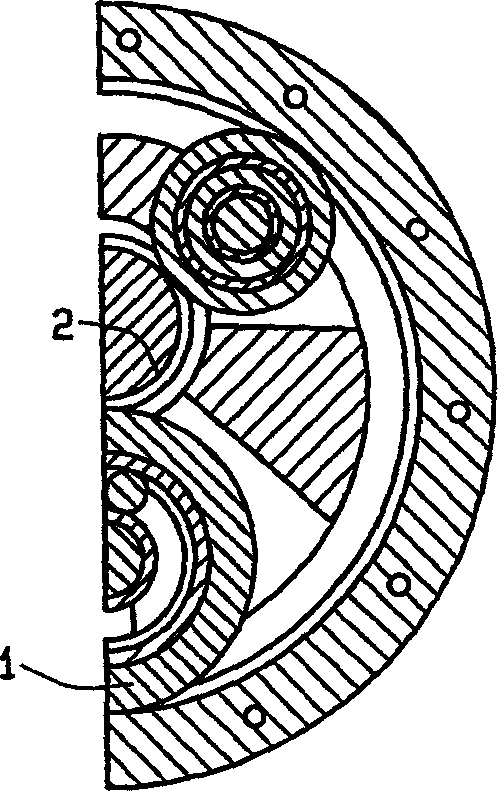

[0040] now refer to figure 1 , figure 2 and image 3 Describes a typical eccentric planetary wheel drive with an eccentric center roller and at least one of the three planetary rollers being a load planetary roller. In this typical road wheel drive, the inventive wedge-shaped load mechanism 1 is a planetary roller, which is used as a load roller in this typical eccentric planetary road wheel drive. The wedge load mechanism 1 is located between the first raceway 2 and the second raceway 3 . Wedge load mechanism 1 comprises support shaft 4 (see Figure 5 ), rubber pad 5, bearing 6 and load roller ring 7. The shaft 4 is fixed to the wedge load mechanism 1 . The wedge load mechanism 1 is positioned between and in contact with the first raceway 2 and the second raceway 3 . exist Figure 6 , the tangent to the contact point A between the second raceway 3 and the wedge load mechanism 1 OA Tangent with respect to the contact point B between the first raceway 2 and the wedge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com