Clinch-type blind nut

A technology of blind holes and threads, which is applied in the field of blind hole nut inserts, can solve the problems of limited force of installation tools, etc., and achieve the effect of increasing the clamping range, increasing the upsetting load, and increasing the torsional holding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

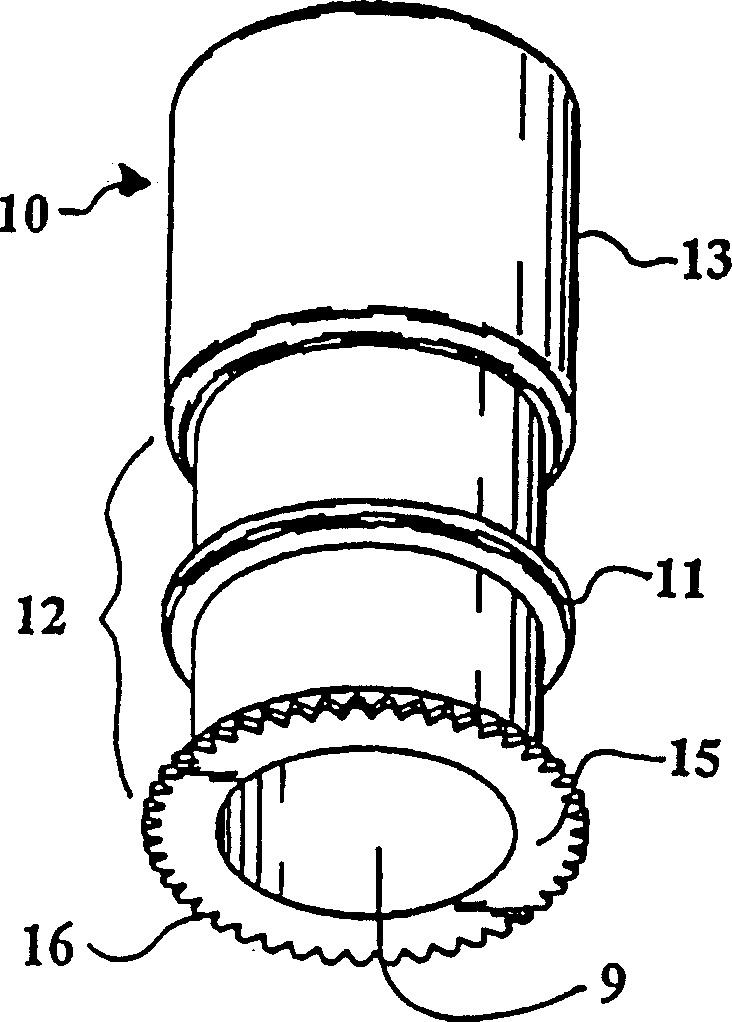

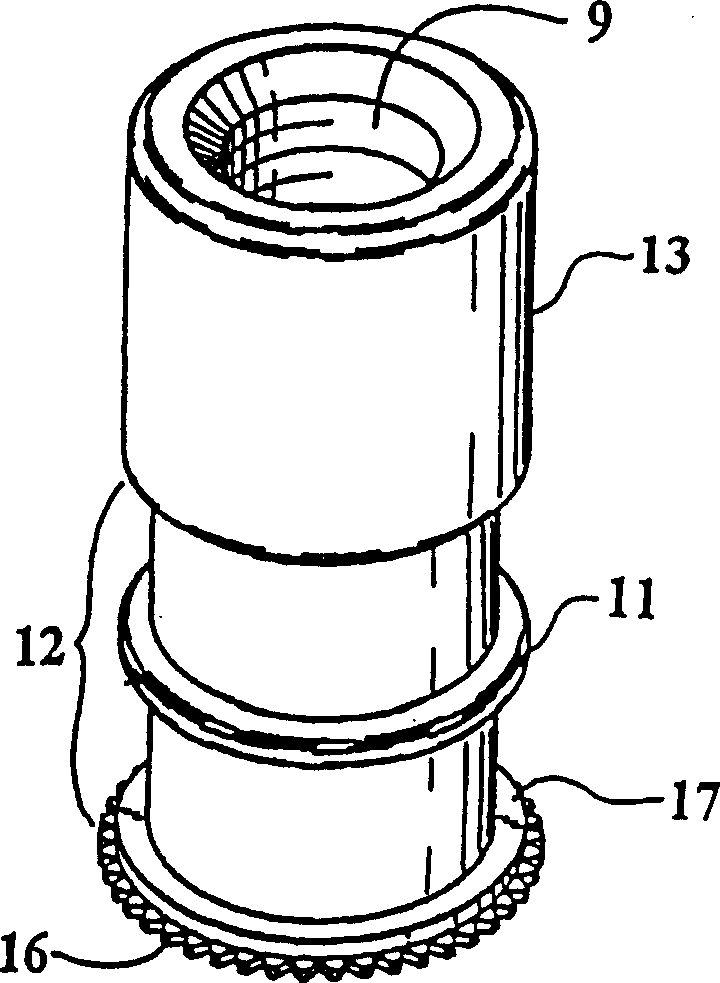

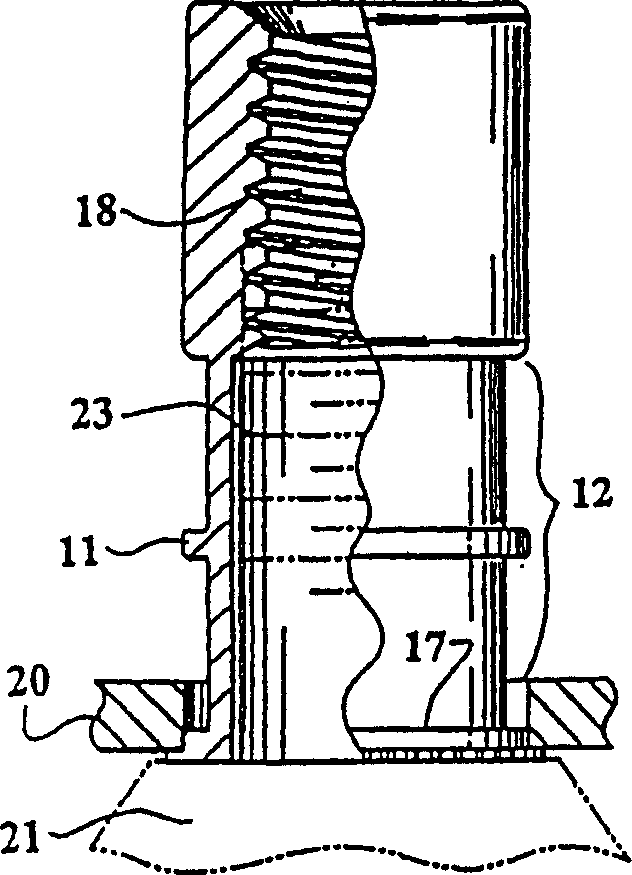

[0020] see figure 1 with figure 2, the insert 10 of the first embodiment of the present invention includes an axial through hole 9 . A radial collar 11 integral with the insert is located in the unthreaded part of the insert close to the center of a deformable zone 12 , the outer diameter of which is smaller than that of the flange 17 . The collar 11 is located slightly closer to the threaded portion 13 of the insert than the head 15 is. Head 15 includes a knurl 16 commonly used on certain types of self-tightening inserts known to provide high torsional strength when pressed into a workpiece. The hardness of the knurling is greater than that of the workpiece. A flange 17 on the underside of the head 15 centers the insert in the mounting hole of the workpiece, leaving an annular gap between the unthreaded portion and the side walls of the hole. The axial length of the flange must be slightly less than the minimum thickness of the sheet in order for the insert to fit in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com