Chain mat of moulding machine

A casting machine and chain plate technology, which is applied in foundry workshops, casting equipment, pig iron foundry workshops, etc., can solve problems such as chain plate damage, weld joint disconnection, and center protrusion plate connection hole wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

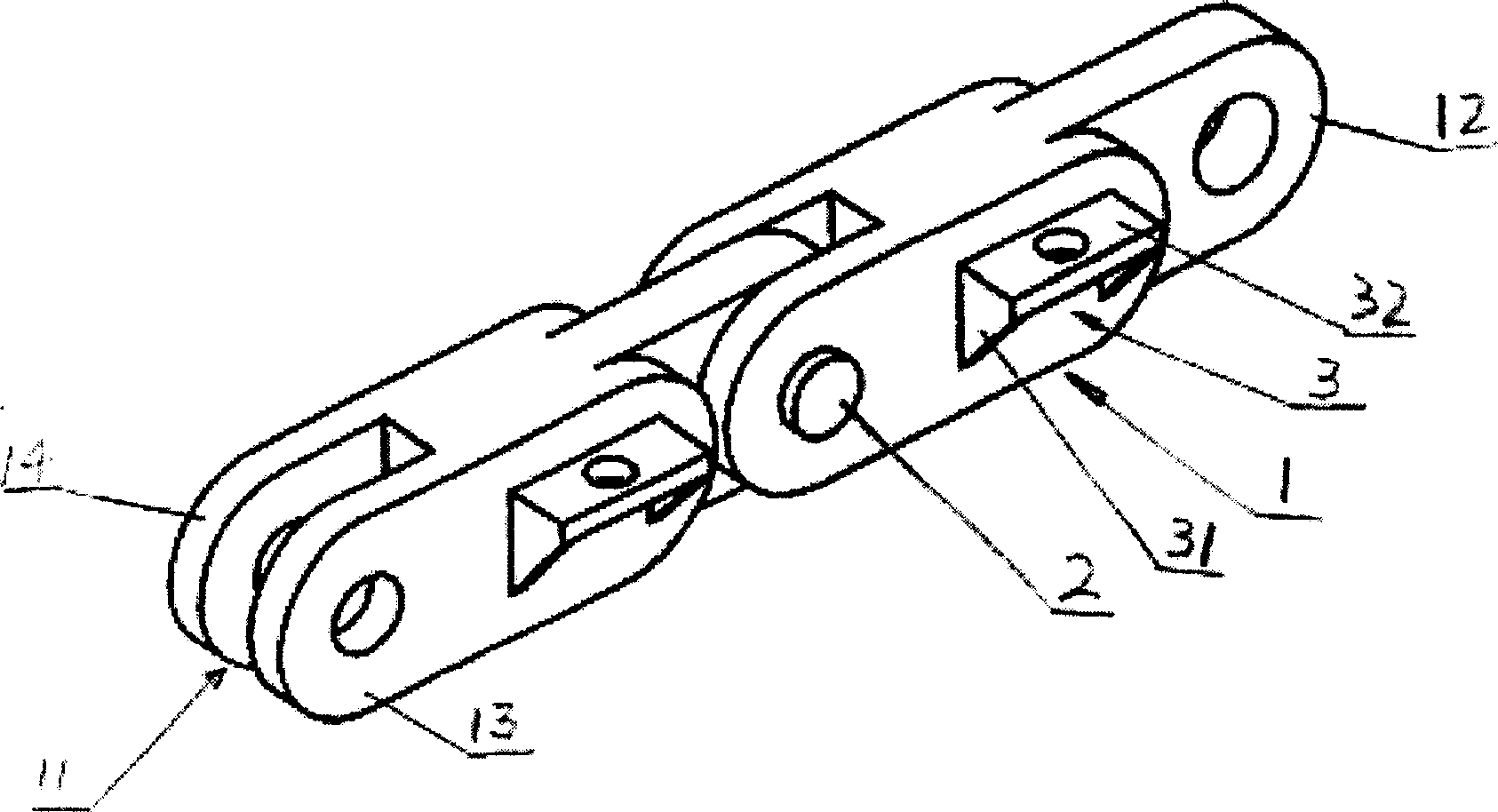

[0014] see figure 1 , this figure provides the appearance overall structure when two chain plates 1 are connected together in the casting machine chain plate proposed by the present invention. The chain plate 1 is a whole made of cast steel material, and is an irregular plate-shaped element from the appearance. The cast steel material used for the chain plate 1 is preferably composed of an alloy (by weight percentage) including the following chemical composition: C: 0.90-1.40, Si: 0.30-0.80, Mn: 11.0-14.0, and the balance is mainly Fe and not Avoid impurities. The cast steel material can also be made of other types of steel, that is, as long as it is a wear-resistant and high-temperature-resistant steel material, the task of the present invention can be accomplished.

[0015] One end of the chain plate 1 is provided with a vertical through-slot 11 which is recessed inward along its end face along the length direction of the plate, and its other end is provided with a middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com