Automatic ink feeder for ink jet printer

An inkjet printer and ink supply technology, applied in printing and other directions, can solve problems such as increased costs, irregular connection ports, backflow, etc., and achieve the effect of reducing printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

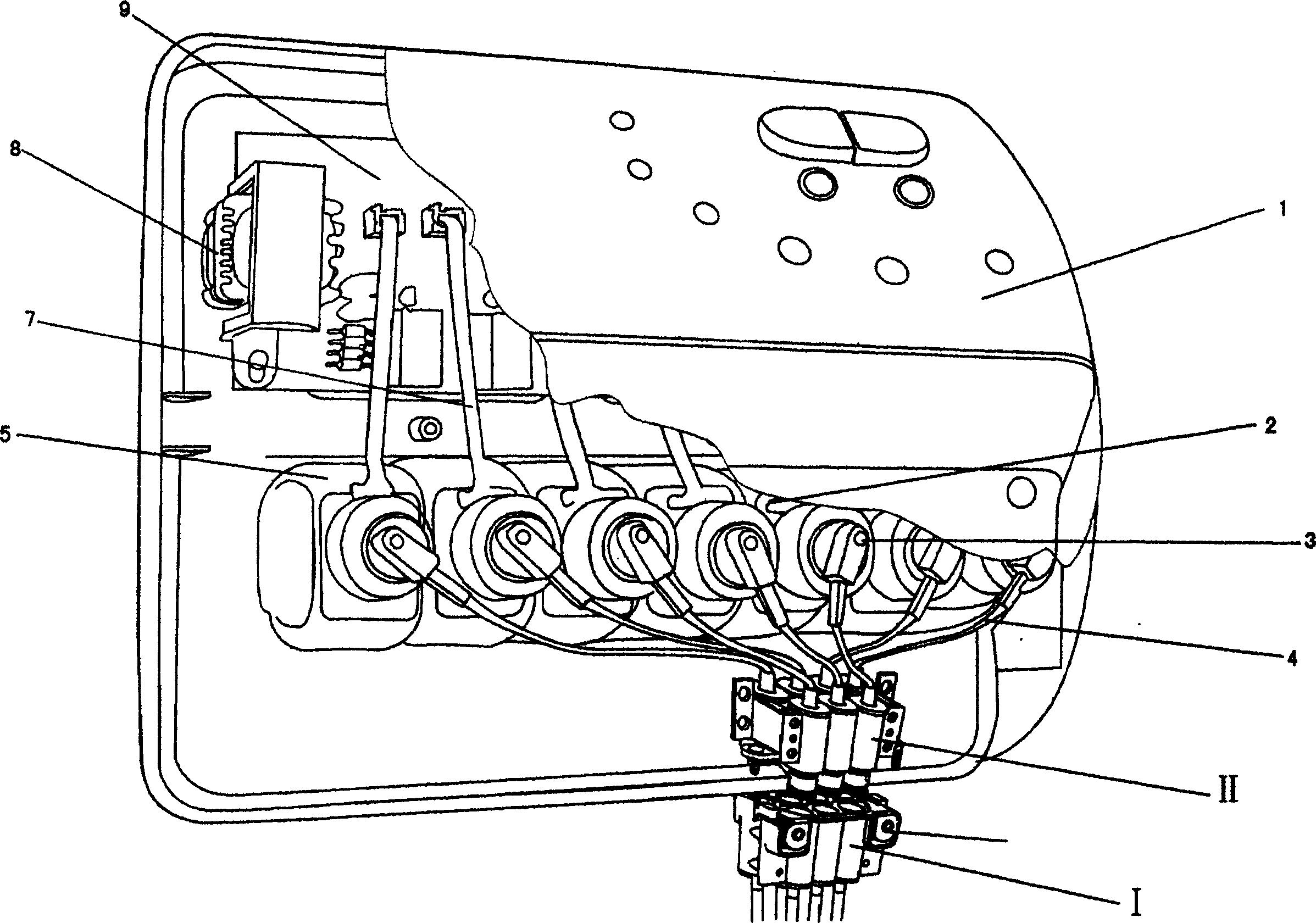

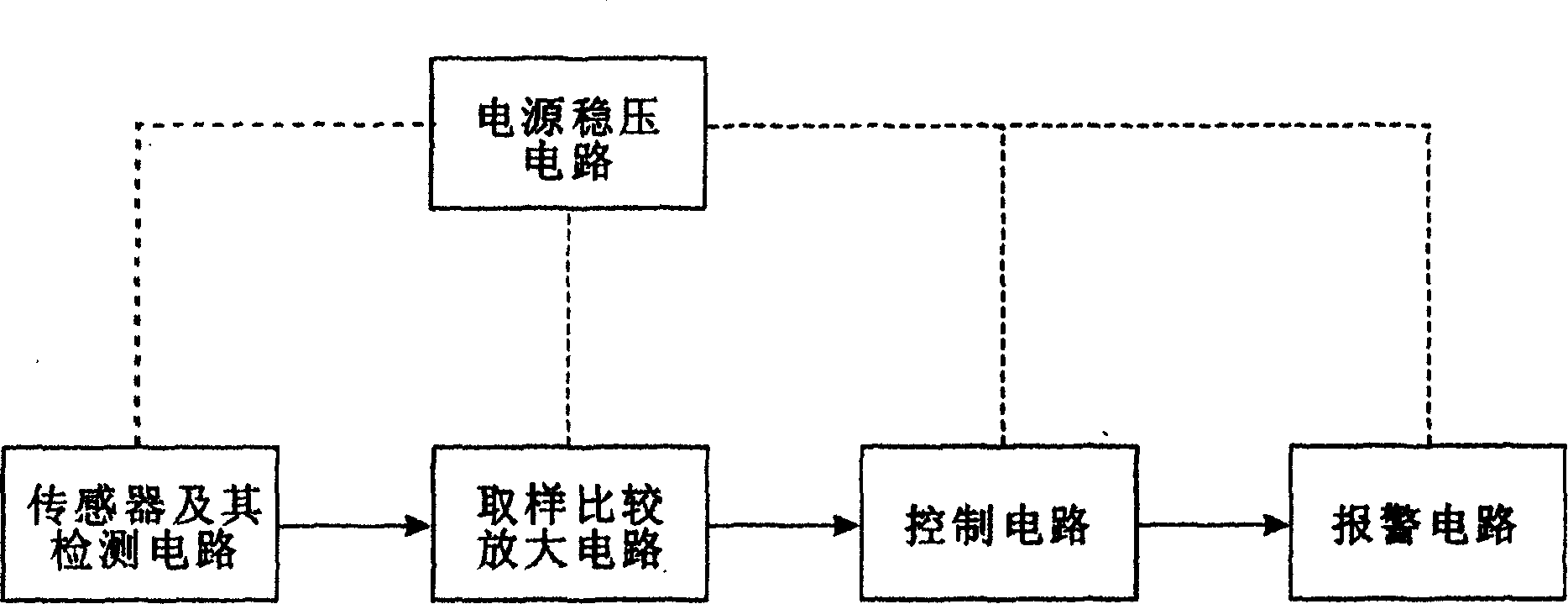

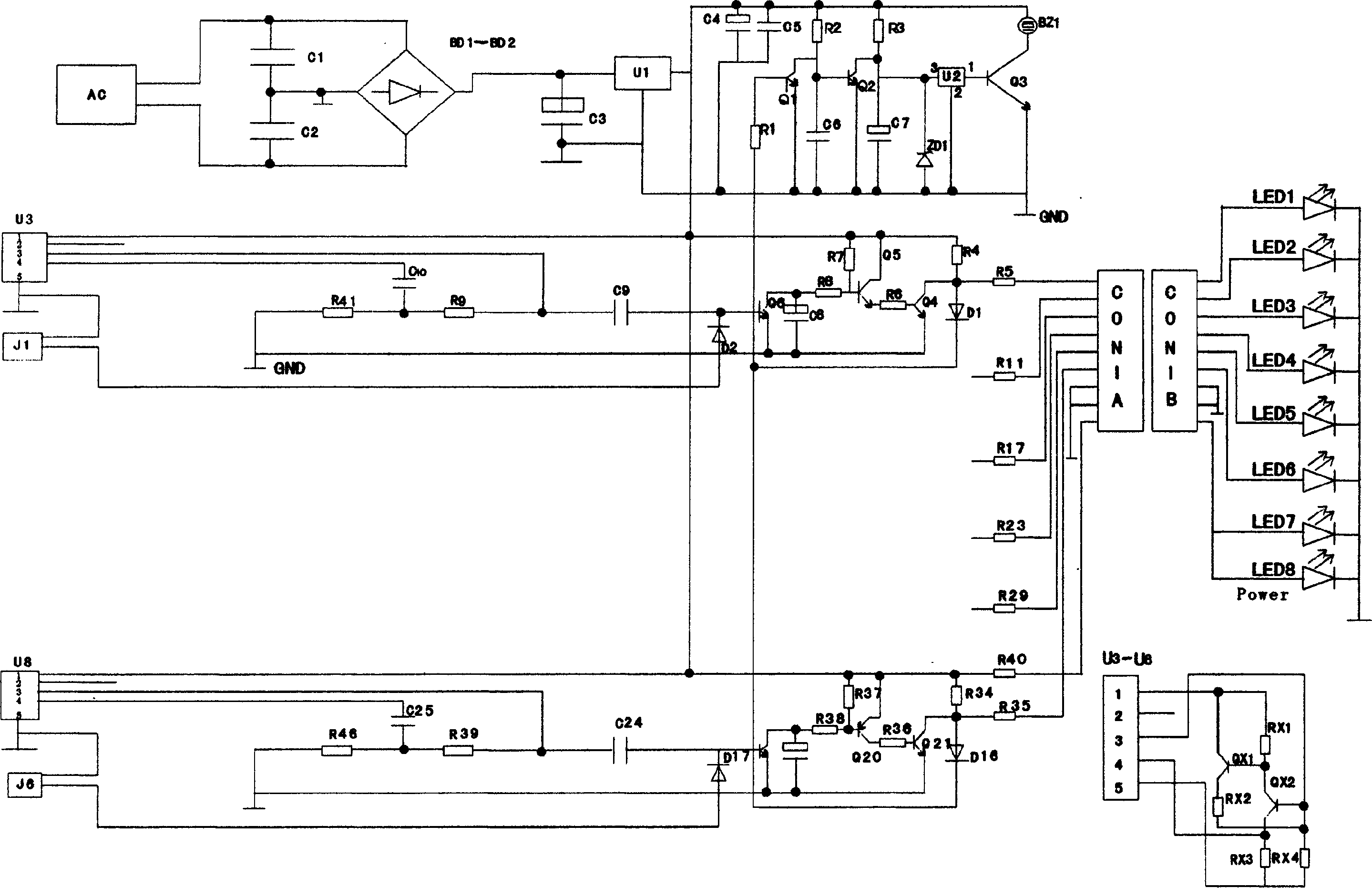

[0042] Depend on figure 1 , 2 As shown, 1 among the figure is the ink supply unit housing, and six ink supply unit ink tanks 2 whose tops are provided with ink filling ports 3 are distributed in the housing. Figure 4 Shown) the outlet end is provided with an ink conduit 4 that is connected with the upper part of the inkjet printer print cartridge, and at the bottom of the ink tank 2 of the ink supply device (such as Figure 5 Shown) the outlet end is provided with an ink conduit 4' that is connected with the upper part of the inkjet printer print cartridge. There is a probe-type liquid level sensor 6 in the ink tank of the ink supply unit, and the probe-type liquid level sensor is connected with the detection circuit in the ink supply unit housing, the sampling comparison amplifier circuit, the control circuit, and the music alarm circuit in sequence through the connection 7 wires concatenated (such as figure 2 Shown), in the whole circuit, also connect a power supply vol...

example 2

[0054] by 12- Figure 18 As shown, according to the needs of the present invention, an ink conduit cut-off switch is arranged on the ink conduit in the ink supply housing. 20 in the figure is a switch housing. A valve body 21 with seven independent cavities 22 arranged side by side is arranged on the lower part of the switch housing 20. A An ink inlet pipeline interface 23 and an ink outlet pipeline interface 24 . The top of the valve body 21 is connected with an ink tube closing key 26 through a pressure spring 35, and the lower part of the ink tube closing key is fixedly connected with a valve stem 25 corresponding to the independent cavity 22 of the valve body and inserted into the cavity. An annular sealing ring 34 is also provided on the periphery of the lower part. On the outer wall of ink tube closing key 26, a movable lock key socket 27 is symmetrically arranged, and a switch housing 20 corresponding to the movable lock key socket 27 is provided with a movable lock k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com