Steel wire for high-tension bolts and method for manufacturing high-tension bolts

A technology of high-strength bolts and manufacturing methods, applied in the directions of screws, threaded fasteners, connecting components, etc., can solve the problems of uneconomical, uneven delayed damage resistance of high-strength bolts, and the incidence of defective bolts, so as to avoid damage. and bite, eliminating the unevenness of delayed failure, good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The best mode for carrying out the present invention will be described below with reference to the drawings.

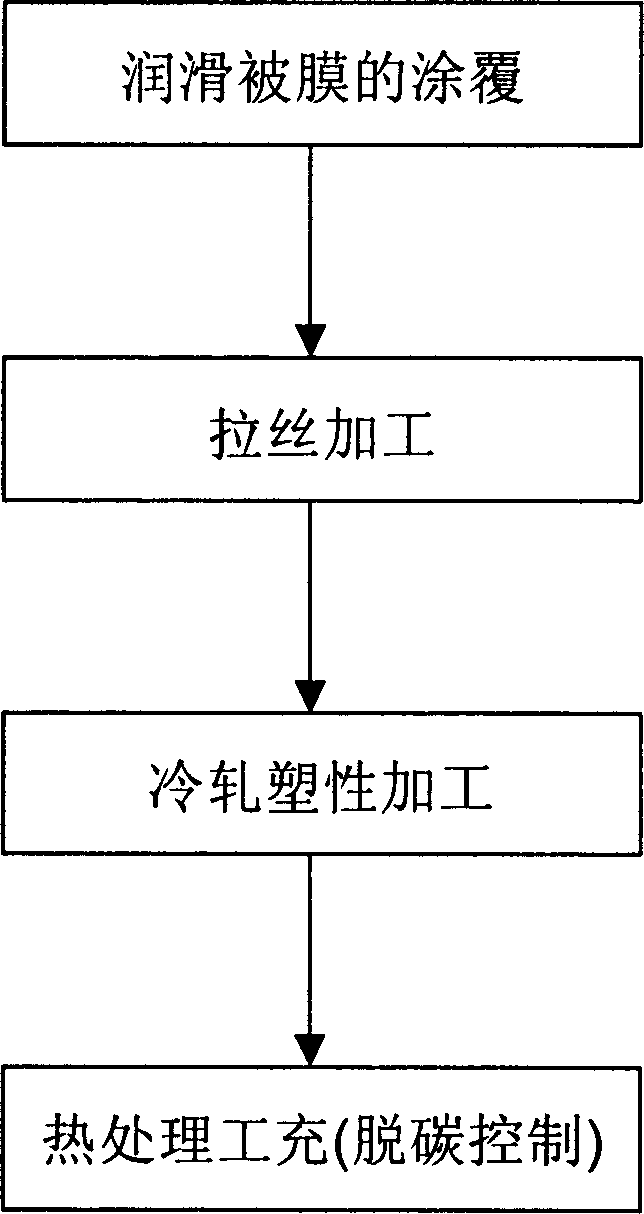

[0019] (1) Application of lubricating film

[0020] Such as figure 1 As shown, when high-strength bolts are manufactured using steel wire for high-strength bolts as a base, steel wires such as SCM435, 440H and boron steel are coated with a lubricating film and then drawn to a specified diameter. Furthermore, cold-rolled plastic processing is performed so that the overall shape of the bolt head and the bolt shaft portion appears, and the semi-finished bolt is heat-treated. Finally, the thread is threaded on the shaft of the bolt to obtain a high-strength bolt.

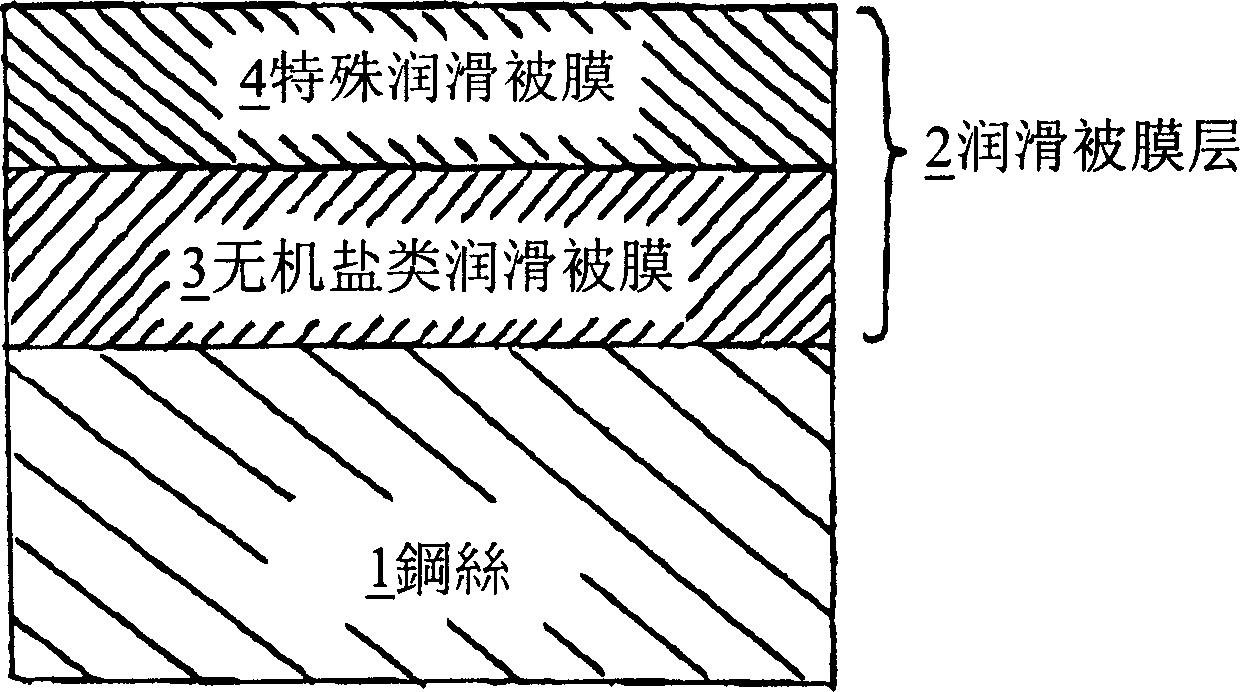

[0021] The invention as figure 2 As shown, the surface of the steel wire 1 is coated with a lubricating coating layer 2 of a multi-layer structure that has never been seen before.

[0022] The lubricating film layer 2 is composed of an inorganic salt lubricating film 3 directly coated on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com