Environment-friendly type underground power cable

A power cable and environmentally friendly technology, applied in the field of environmentally friendly subway power cables, can solve the problems of a large amount of smoke, troublesome fire and rescue work, and the cable will inevitably not burn, and achieve low smoke density and small emission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

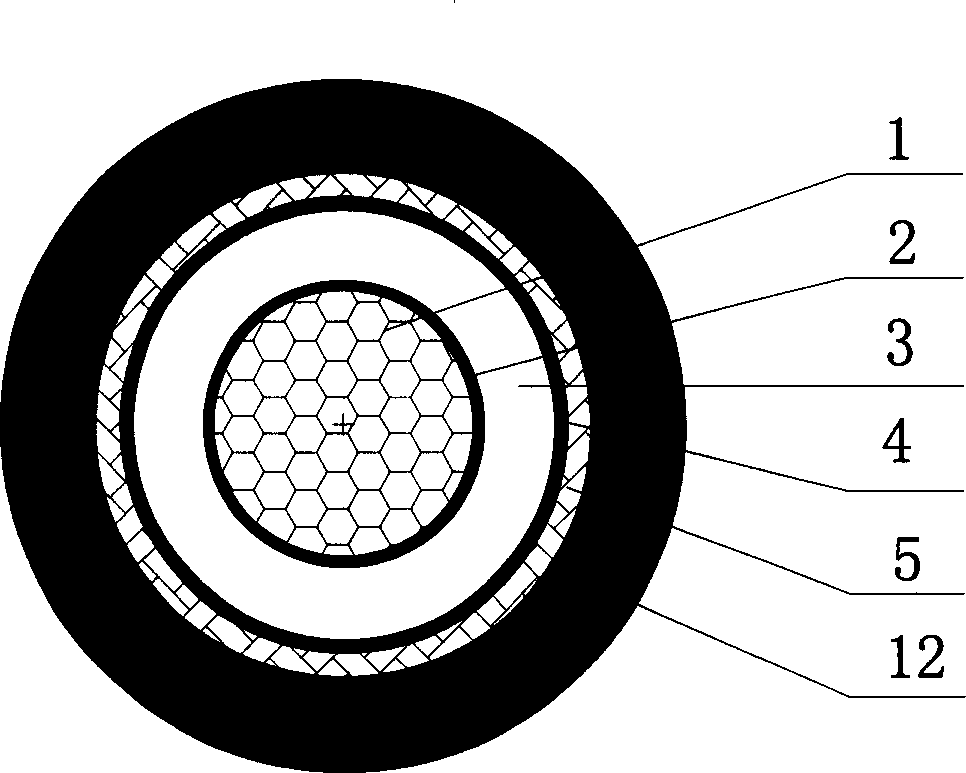

Embodiment 1

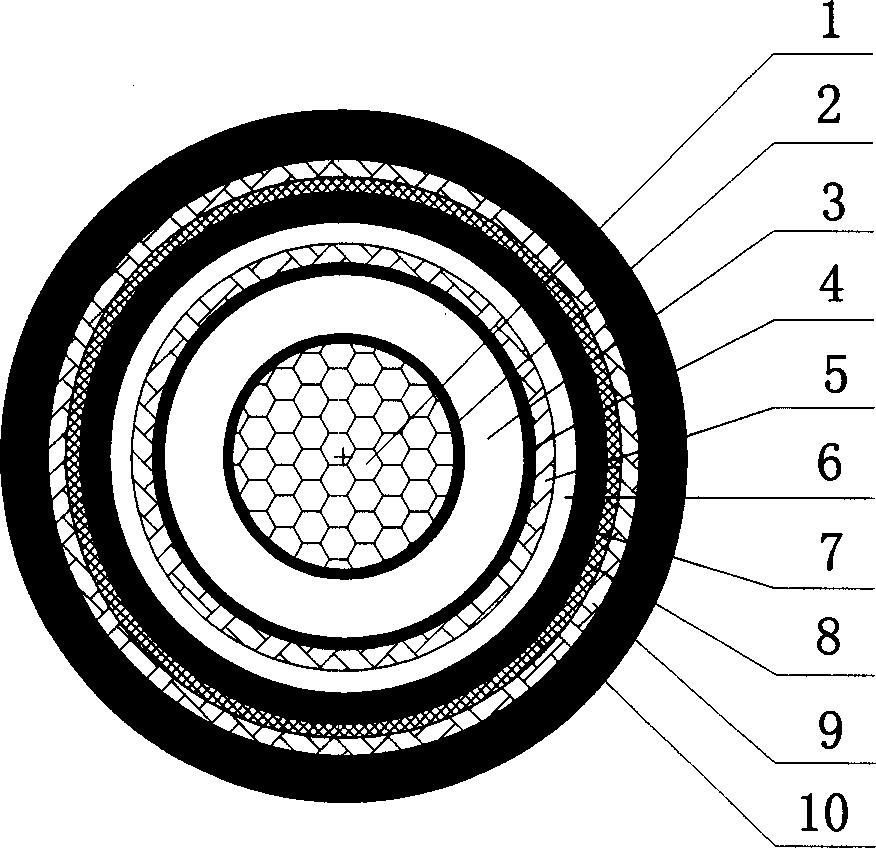

[0016] Embodiment 1: as figure 2 As shown, in the present embodiment, the present invention has conductor 1, inner semiconductive shielding layer 2, insulating layer 3, outer semiconductive shielding layer 4, metal shielding layer 5 from inside to outside successively, and metal shielding layer 5 has special outer protection Layer 12, the special outer sheath 12 includes a water-blocking layer 6, a high-density polyethylene sheath 7, an oxygen barrier layer 8, an armor layer 9, and a low-smoke and halogen-free sheath 10 from inside to outside.

Embodiment 2

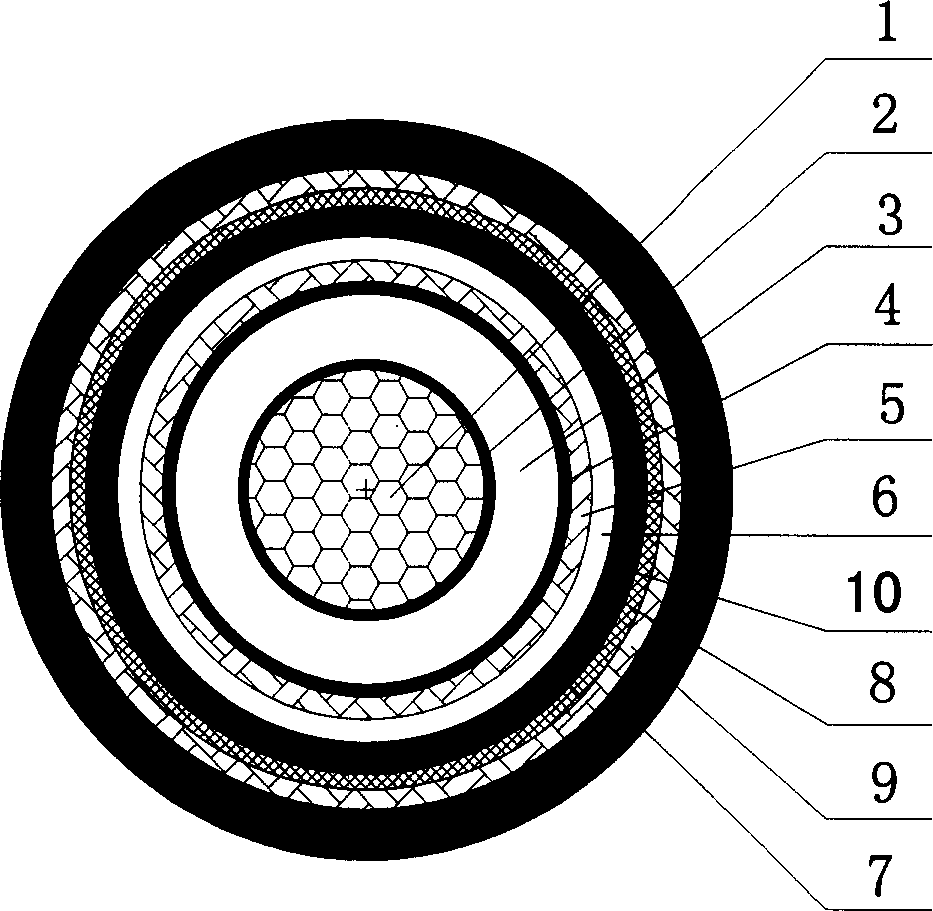

[0017] Embodiment 2: as image 3 As shown, in this embodiment, the present invention has a conductor 1, an inner semiconductive shielding layer 2, an insulating layer 3, an outer semiconductive shielding layer 4, and a metal shielding layer 5 from the inside to the outside. The sheath 12, the special outer sheath 12 includes a water blocking layer 6, a low-smoke and halogen-free sheath 10, an oxygen barrier layer 8, an armor layer 9, and a high-density polyethylene sheath 7 from inside to outside.

Embodiment 3

[0018] Embodiment 3: as Figure 4 As shown, in the present embodiment, the present invention has conductor 1, inner semiconductive shielding layer 2, insulating layer 3, outer semiconductive shielding layer 4, metal shielding layer 5 from inside to outside successively, and metal shielding layer 5 has special outer protection Layer 12, the special outer sheath 12 includes a water-blocking layer 6, a high-density polyethylene sheath 7, an oxygen barrier layer 8, an armor layer 9, and a low-smoke and halogen-free sheath 10 from inside to outside. There is a semiconducting resistive water layer 11 between the metal shielding layer 5 and the outer semiconducting shielding layer 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com