Tendon of wrapping mortar on it in advance and bonded in later

A bonding prestressing and prepacking technology, applied to structural elements, building components, building reinforcements, etc., can solve problems such as low bonding strength and weak gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

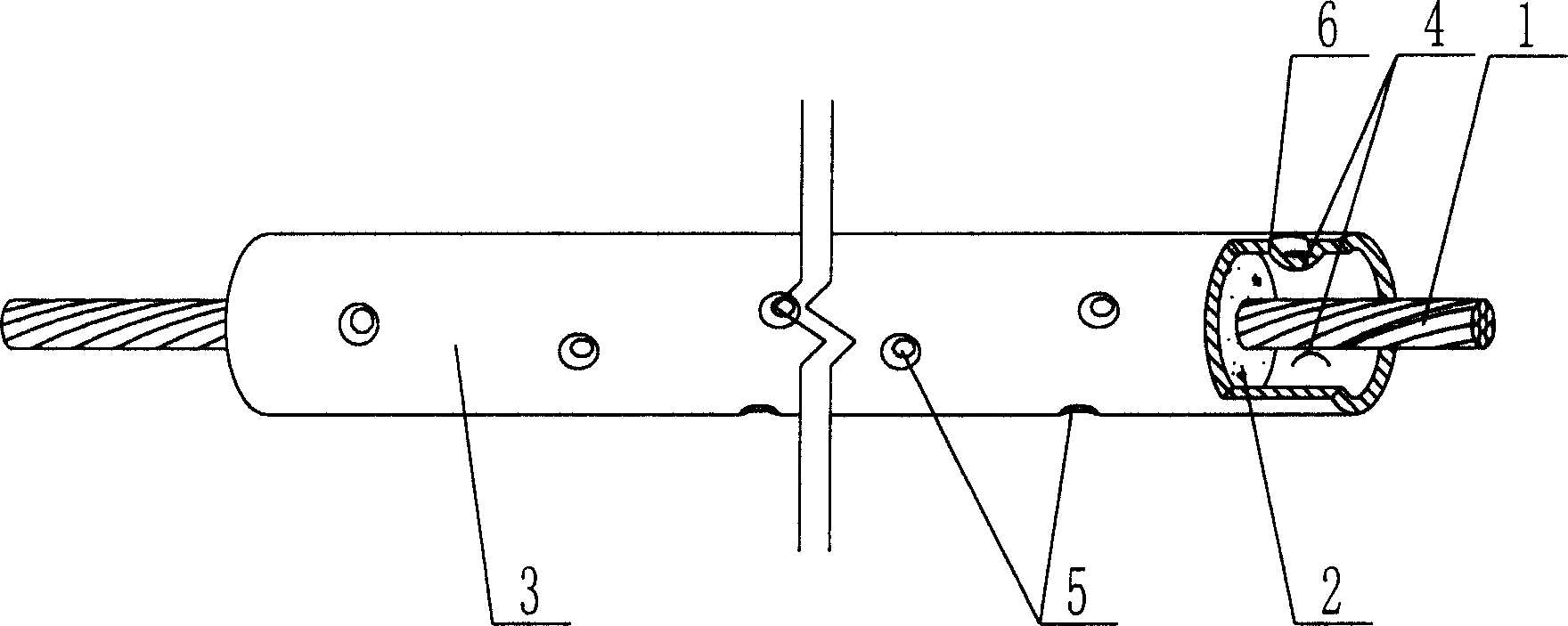

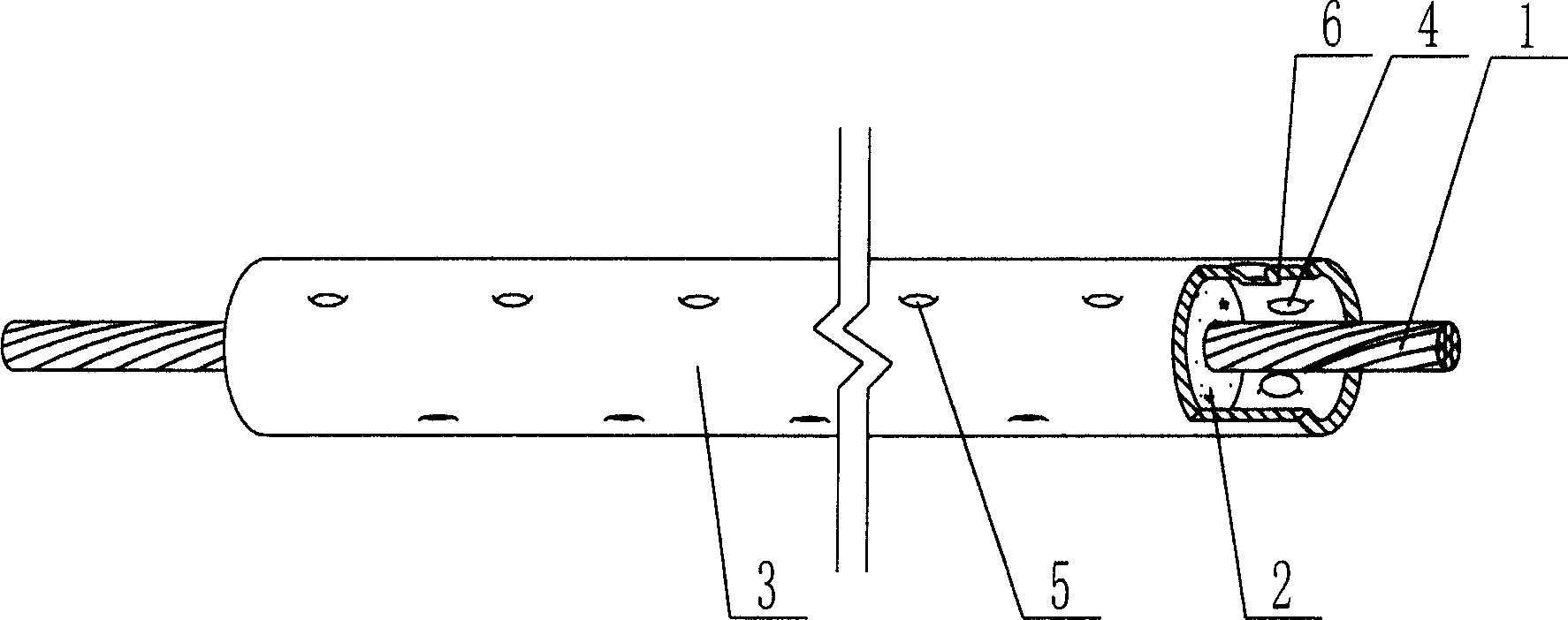

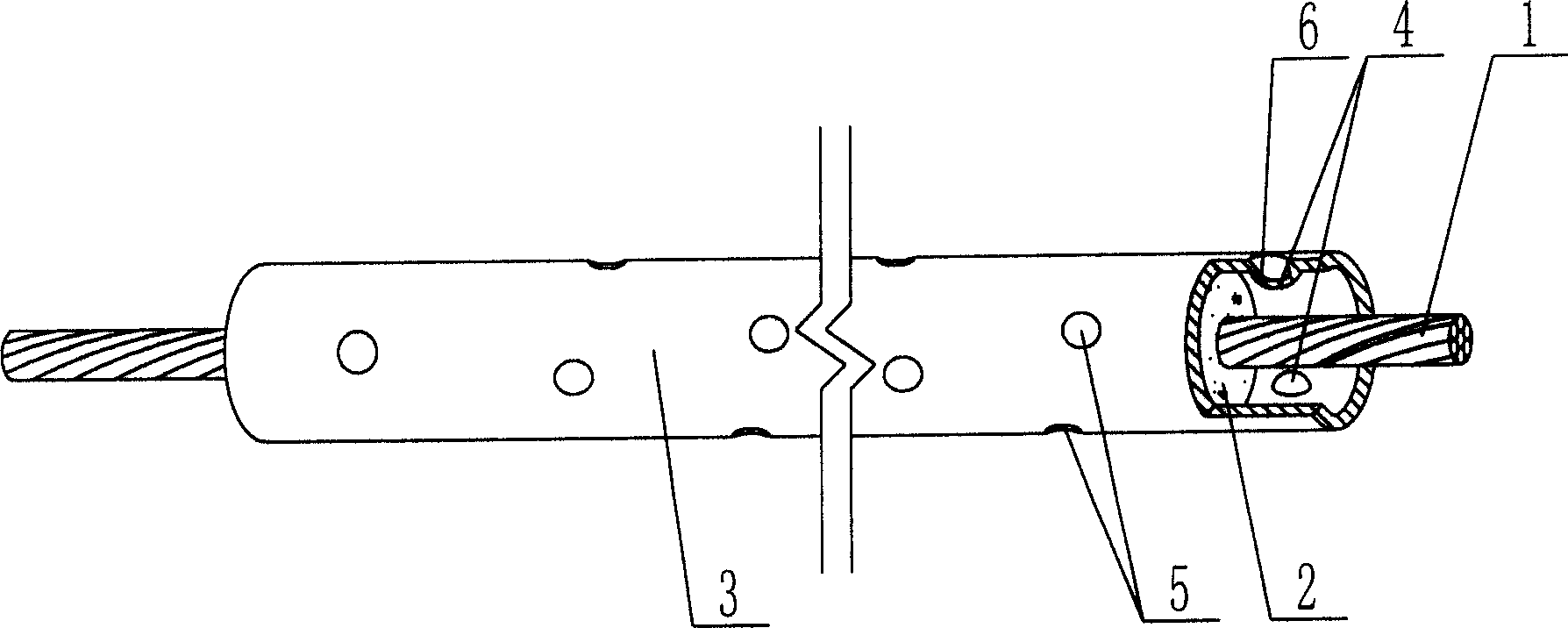

[0036] As shown in the accompanying drawings, the present invention includes a steel strand 1, a post-bonding slurry 2, and a sheath 3. The steel strand 1 is arranged in the sheath 3, and the space between the steel strand 1 and the sheath 3 is filled with post-bonding The slurry 2 is characterized in that the inner surface of the sheath 3 is provided with a convex structure 4, and at the same time, the outer surface of the sheath 3 is also provided with a concave structure 5, and the convex structure 4 of the inner surface is connected with the concave structure 5 of the outer surface. Stacked. figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. In each drawing, 1 is a steel strand, 2 is a post-bonding slurry, 3 is a sheath, 4 is a convex structure, and 5 is a concave structure. In the following drawings, those with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com