Display device producing method and display device producing device

A technology for display devices and manufacturing equipment, which is applied in optics, instruments, discharge tubes, etc., and can solve problems such as light transmission and adverse effects on image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0023] The first embodiment of the present invention will be described below by referring to the drawings.

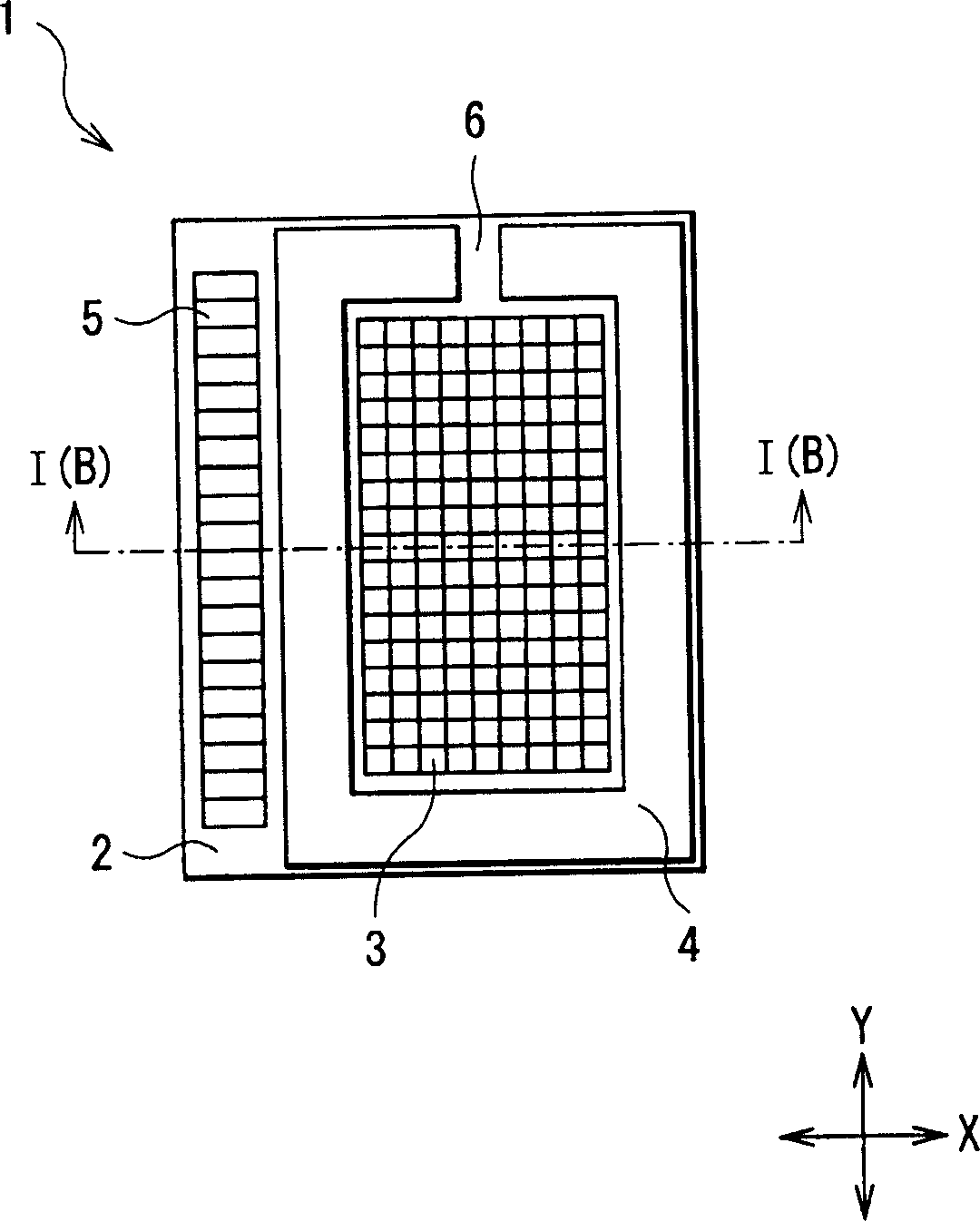

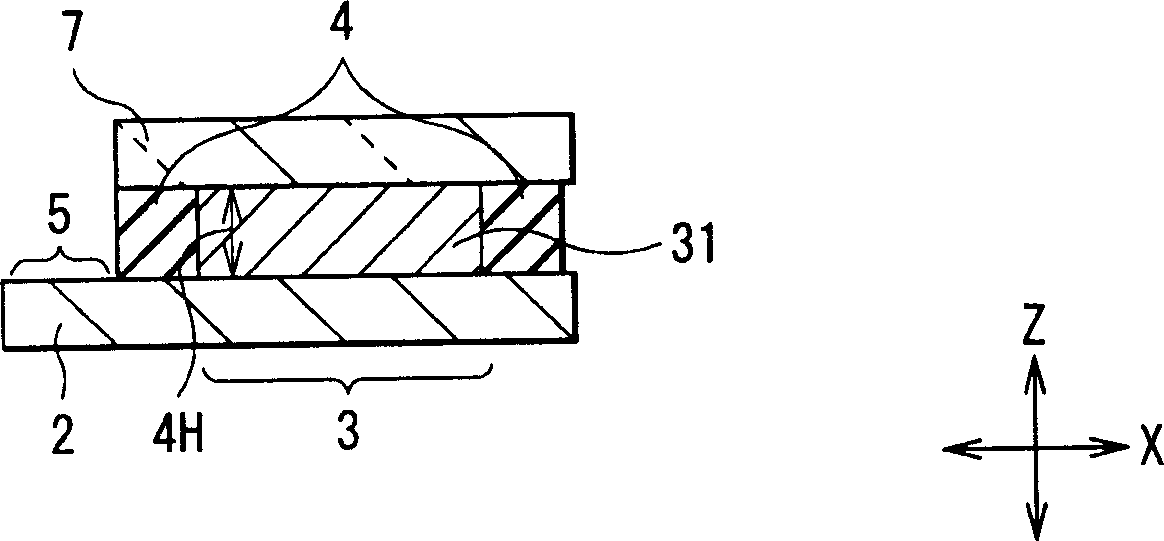

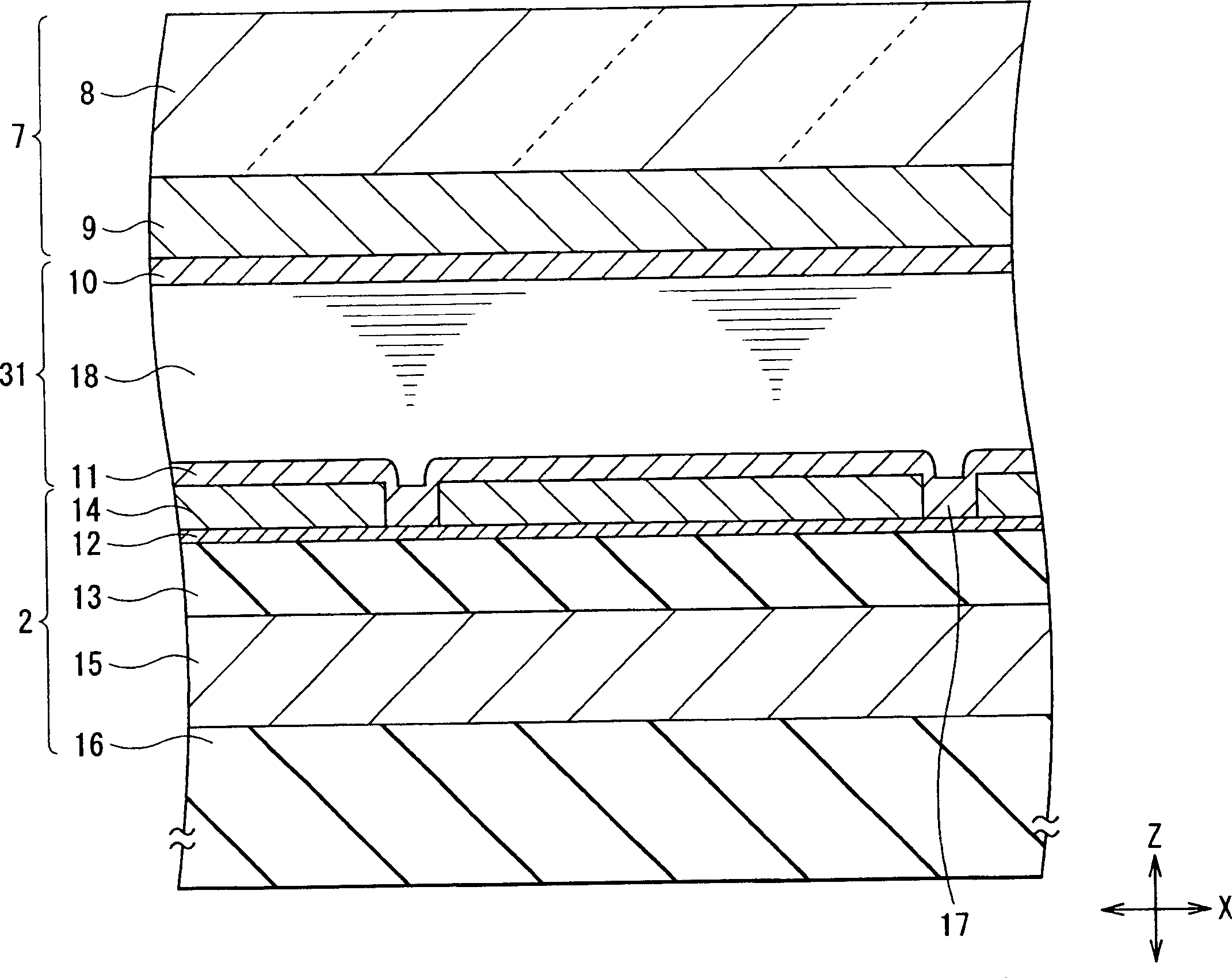

[0024] First, refer to Figure 1A with 1B The structure of the display device according to the embodiment of the present invention will be described below.

[0025] Figure 1A with 1B The structure of the display panel 1 is shown, which is the main part of the display device according to the present embodiment. Figure 1A Shows a plan view directly from above, and Figure 1B Is along the arrow direction Figure 1A A cross-sectional view taken from the line I(B)-I(B). The display panel 1 is formed as an active matrix reflective liquid crystal display device. in Figure 1A In order to facilitate understanding, the top substrate 7 is shown (which will be described below).

[0026] Such as Figure 1A with 1B As shown, the display panel 1 includes a rectangular bottom substrate 2 and a rectangular top substrate 7, and a display portion 31 and a sealing pattern 4 sandwiched betw...

no. 2 example

[0062] Below, reference Figure 11A with 11B In the following, a method of manufacturing a display device and a display device manufacturing apparatus according to a second embodiment of the present invention will be described.

[0063] Figure 11A with 11B The bonding apparatus according to the present embodiment is shown as a display device manufacturing apparatus, and is similar to that in the first embodiment Figure 5A with Figure 5B Corresponding. Such as Figure 5A with 5B Case, Figure 11A Shows the open state before pressure is applied, and Figure 11B Shows the state of applying pressure. in Figure 11A with 11B In, the same components are used with Figure 5A with 5B The same reference numerals are used for identification.

[0064] In the following description, the main differences between the display device manufacturing method and display device manufacturing apparatus according to this embodiment and the first embodiment will be described below, and other points wil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com