Multifunctional multi-effect distilled water machine

A distilled water machine, multi-functional technology, applied in the direction of multi-effect evaporation, heating water/sewage treatment, etc., can solve the problems of reduced evaporation efficiency, increased production costs, waste, etc., to achieve small equipment footprint, high work efficiency, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

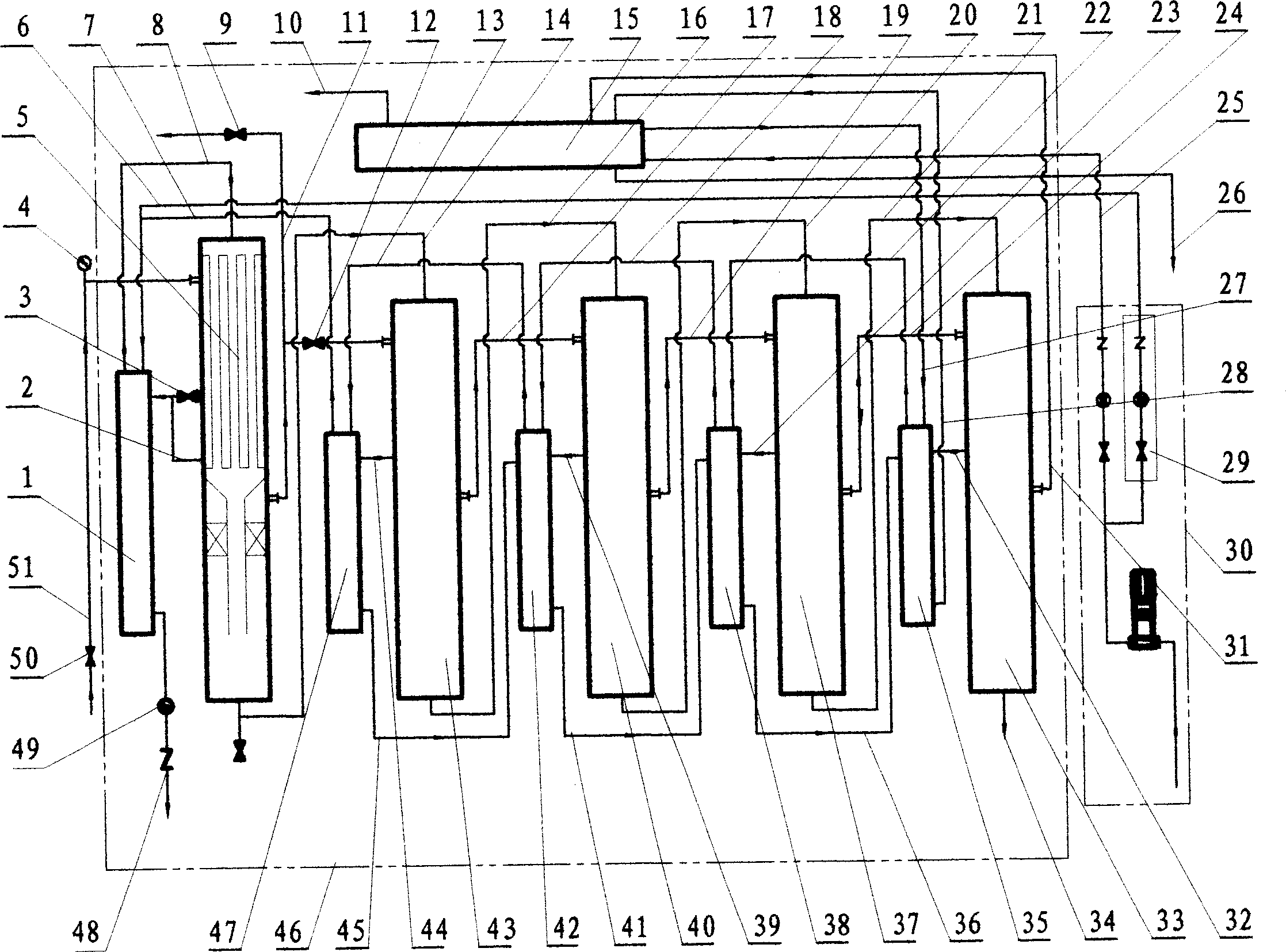

[0013] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] This embodiment includes a purified water inlet operating device 30 and a multi-effect distilled water machine 46 connected thereto.

[0015] The purified water inlet operation device 30 is composed of a water pump, a valve, a flow meter and a check valve, and a supplementary purified water inlet metering device 29 consisting of a valve, a flow meter and a check valve is also installed.

[0016] The multi-effect distilled water machine 46 is a five-effect (also can be two-effect or three-effect or four-effect or six-effect or seven-effect) tube type (also can be a coil type) distilled water machine, which includes condenser 15, first to Five effect evaporators 5, 43, 40, 37 and 33 and first to fifth preheaters 1, 47, 42, 38 and 35. The evaporation area of the first effect evaporator 5 and the heating area of the first preheater 1 are larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com