Foam material for removing pollutants and/or heavy metal from floating medium

A foam material and composite foam technology, applied in the field of foam materials, can solve problems such as difficulty in control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Describe the production method of foam material containing adsorbent

[0031] Bayoxide E33 (the particle size is between 0.5 and 2 mm, and its BET is 140 m2 / g) is manufactured by Arcol 1108 And Desmophen 41WB01 is pre-mixed in a standard polyol mixture (Arcol 1108 It is a polyether alcohol containing oxyethylene and oxypropylene units with an average molecular weight of 2000-6000. Desmophen 41WB01 is a polyether polyol with a high ethylene oxide content), and then used as the isocyanate reaction component toluene diisocyanate (Desmodur T80) The mixture is foamed, and additional additives and adjuvants are used at the same time, for example, the siloxane stabilizer OS20 as a siloxane stabilizer , Tertiary amine catalyst Desmorapid DMEA and Dabco 33LV and Desmorapid SO (as tin catalyst). The content of the adsorbed component is 27.8% by weight of the total weight of the reaction mixture, or 29.5% by weight of the total weight of the reaction mixture after t...

Embodiment 2

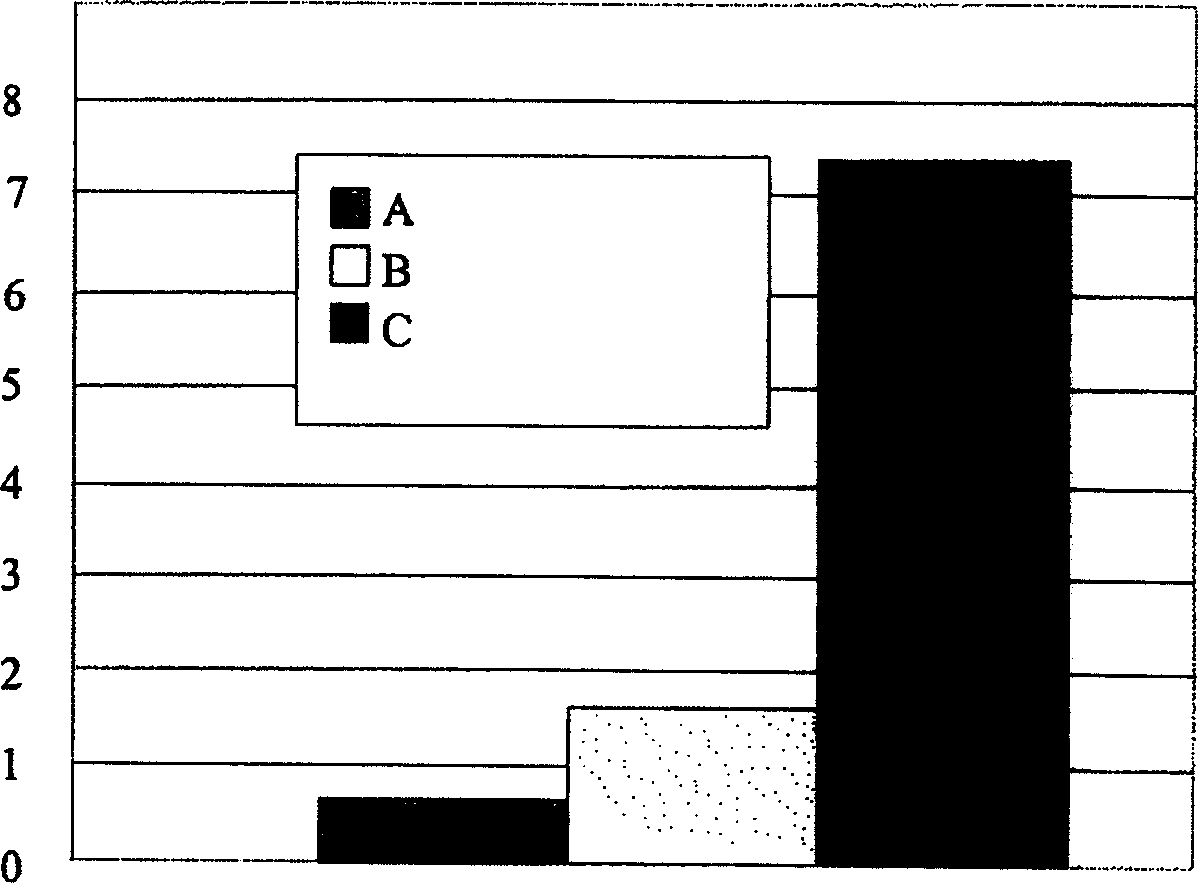

[0043] The foam material containing the adsorbed components produced according to the method of Example 1 was put into a glass tube and rinsed with 250 ml of main pipeline water. For comparison, an equivalent amount of Bayoxide E33 is also filled in a glass tube, and the filter base is made of glass frit of size 1 (aperture width 100-160μm), and the device is also flushed with 250ml of main pipeline water. The effluent filtrate was collected, and the turbidity was measured using the turbidity photometer LTP5 produced by Lange according to the method described in DIN 38404. The turbidity (TE-F) of the main pipeline water is 0.63. Flow through Bayoxide The turbidity of E33 water was 7.30, while the turbidity of water flowing through the foam was 1.60.

[0044] For comparison, the standard BaSO is also listed in Table 1. 4 The turbidity of the suspended matter.

[0045] Sample

deal with

TE-F

BaSO 4

SO 4 (mg / 1)

Flow rate

(l / h)

I

...

Embodiment 3

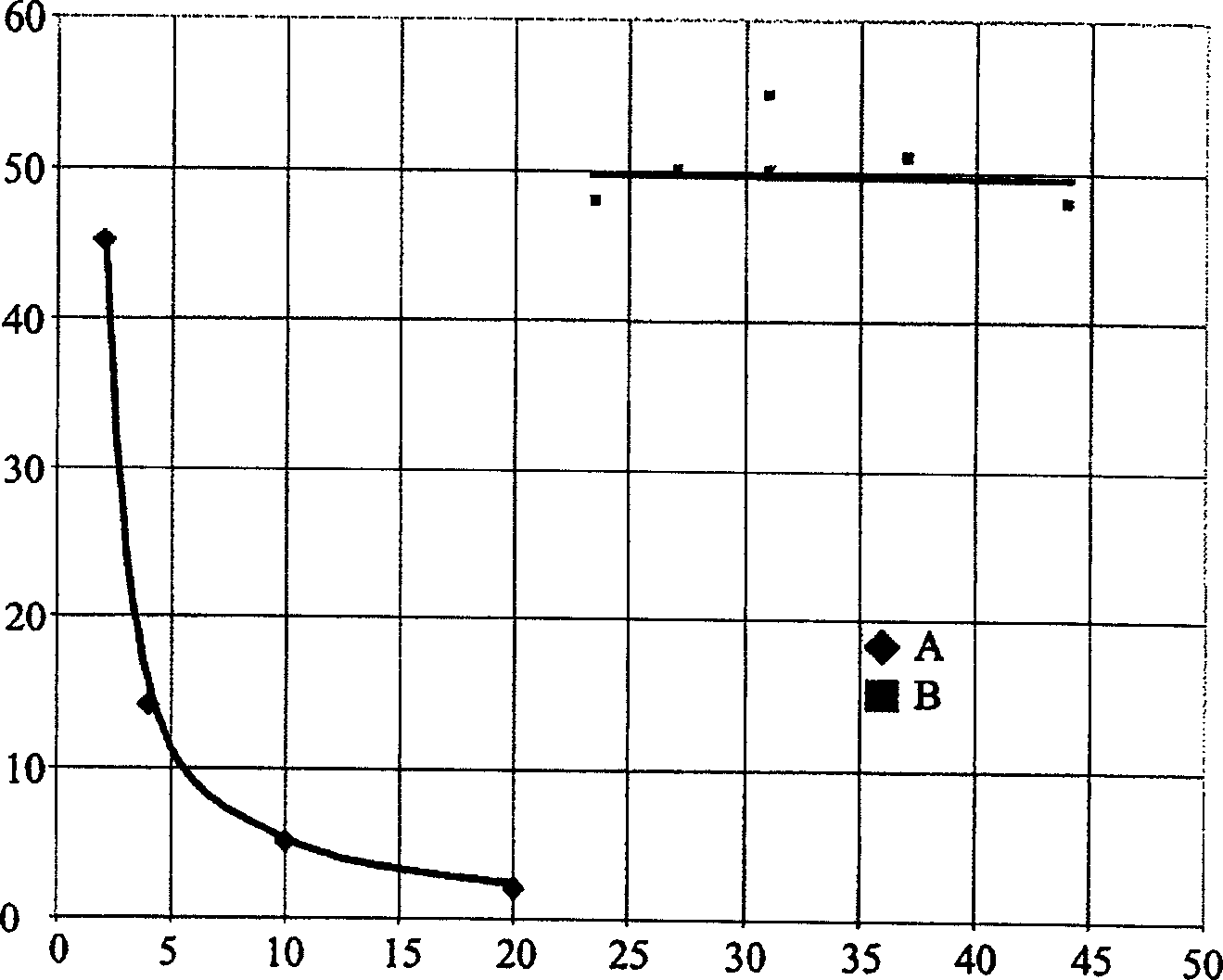

[0049] A solution containing 2.90 mg / l of phosphate was pumped through a foam containing an adsorbent component, and as a comparison, the solution was pumped through an equal amount of adsorbent component. After 60 minutes and 12 hours later, samples were taken and analyzed for phosphate content. The results are summarized in Table 2.

[0050] Sample

Adsorbent

Elapsed time

(Hour)

Phosphate content

(mg / l PO 4 )

Flow rate

(l / h)

1

No

-

2.90

-

2

Bayoxide E33

1

1.05

45

3

Bayoxide E33

12

0.50

45

4

Contains Bayoxide

E33 foam material

1

2.30

45

5

Contains Bayoxide

E33 foam material

12

0.38

45

[0051] The above data shows that the adsorption component (Bayoxide The efficacy of E33) is not impaired by making foam materials.

[0052] In the following exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com