Whole-bridge circuit of raising anti-noise function

A full-bridge circuit, anti-noise technology, applied in the direction of irreversible DC power input conversion to AC power output, etc., can solve the problems of poor anti-noise ability, less selectivity, complex circuit structure, etc., and achieve high anti-noise ability , The effect of simplifying the circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A full-bridge circuit with improved anti-noise function according to a preferred embodiment of the present invention will be described below with reference to related figures, wherein the same components will be described with the same reference symbols.

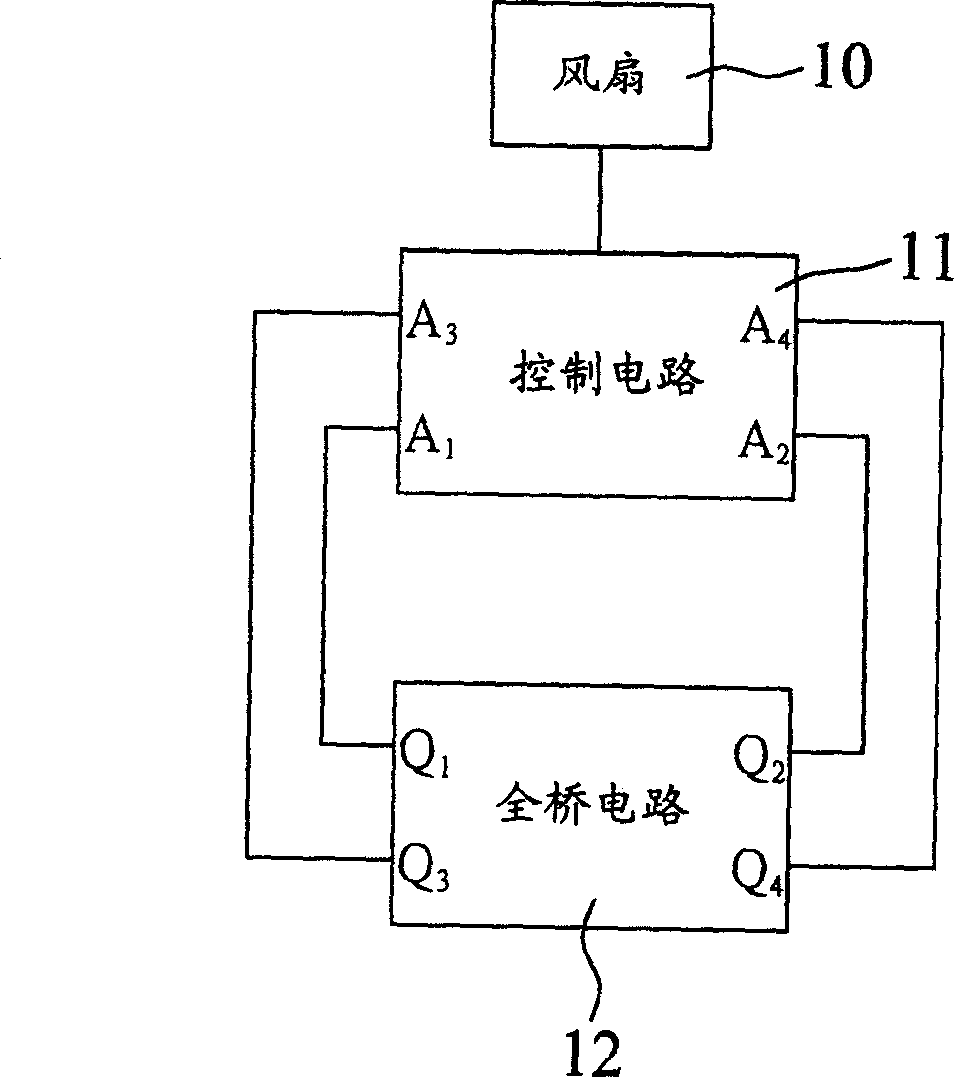

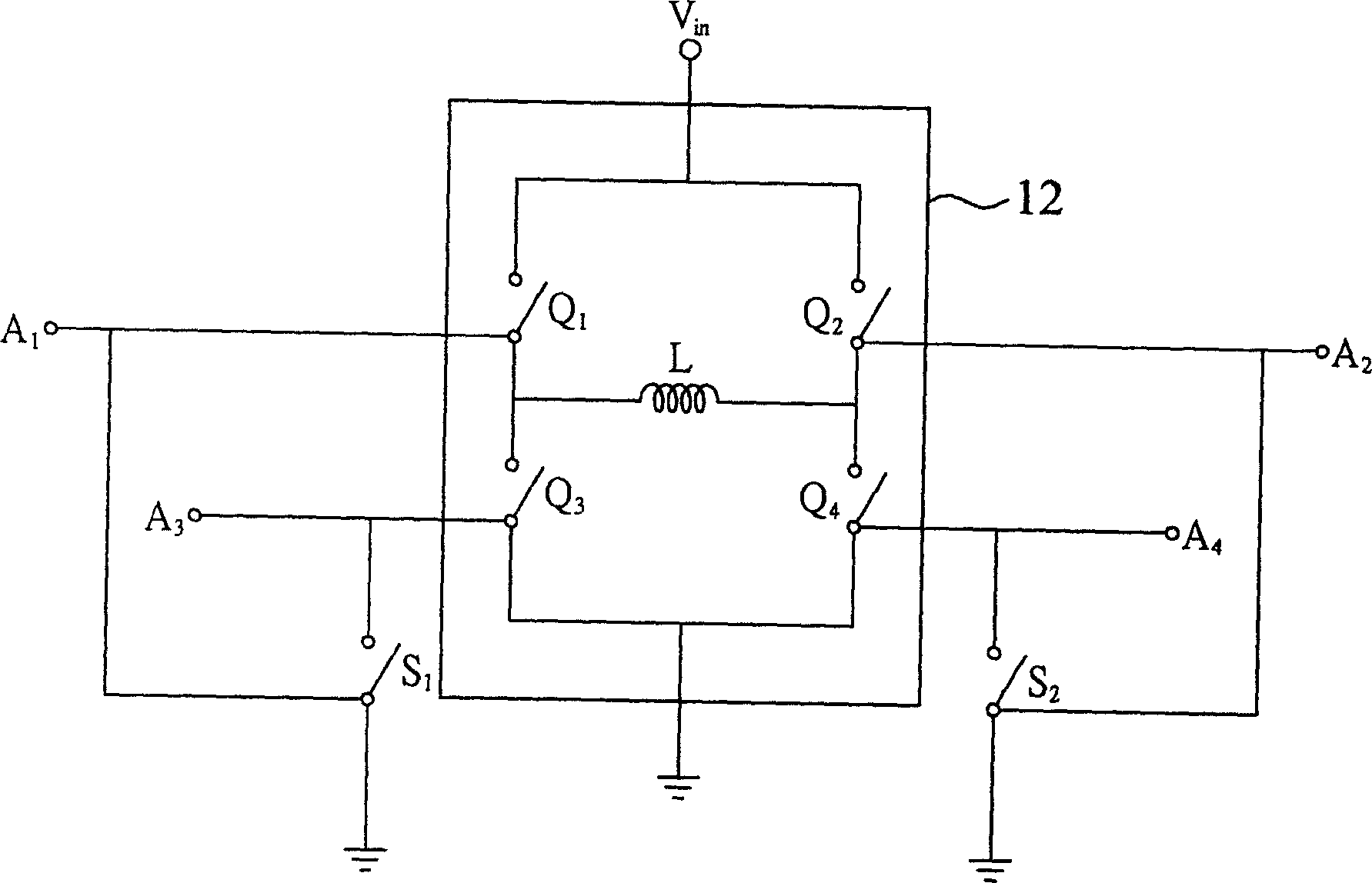

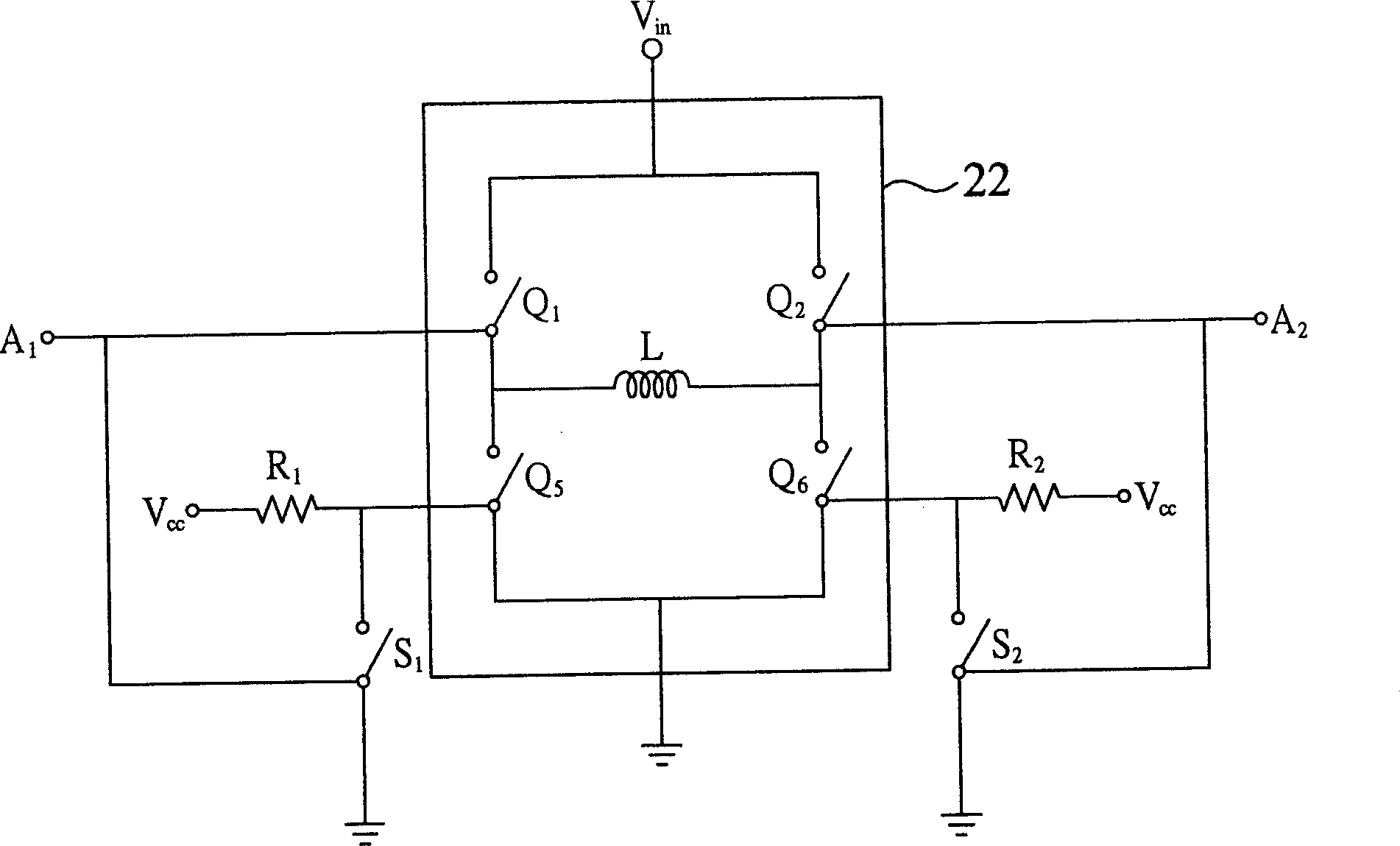

[0018] The full-bridge circuit for improving the anti-noise function of the present invention is applied in a heat dissipation system, and the heat dissipation system further includes a heat dissipation fan and a control circuit. The heat dissipation fan is used to blow a heat dissipation object (not shown) to achieve a heat dissipation effect. The control circuit is also similar to the conventional control circuit, that is, the output control signal is used to control the ON / OFF state of the switch in the full bridge circuit, for example, a microprocessor control unit is used to output the control signal. In other words, the overall structure of the cooling system of the present invention is as Figure 1a The structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com