Insulation oil expansion part for X-ray source

An expansion part, X-ray technology, applied in the directions of X-ray equipment, electrical components, etc., can solve the problems of polluted environment, inconvenient maintenance, high cost, and achieve the effects of simple and reliable operation, simplified structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

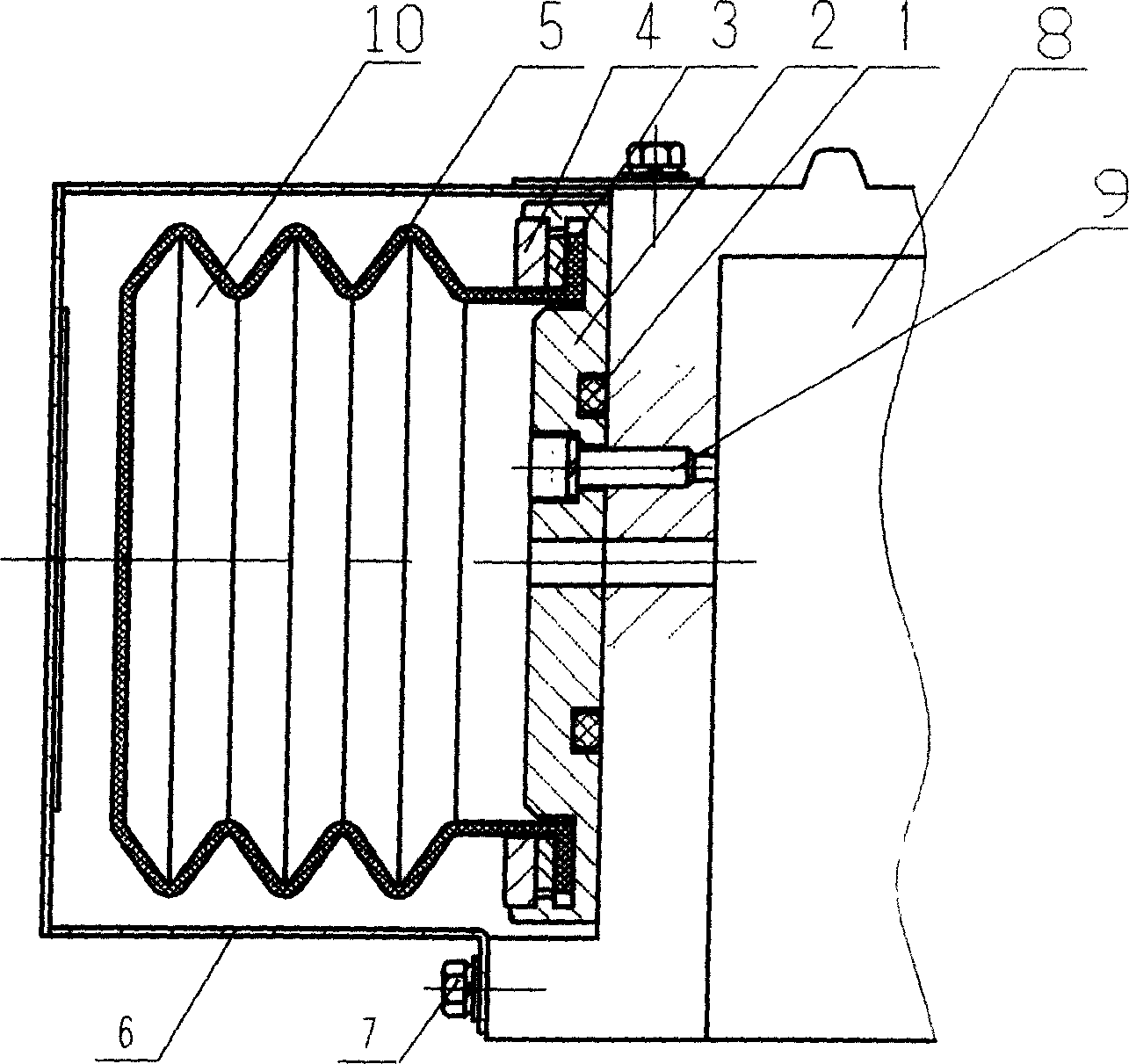

[0021] The specific embodiment of the present invention will now be described in detail in conjunction with the accompanying drawings. First put the sealing ring 1 into the annular groove of the sealing flange 2, and fix the sealing flange 2 on the corresponding position of the X-ray source box 8 with the hexagon socket head cap screw 9, so as to connect the sealing flange 2 to the The sealing connection between the X-ray source boxes 8; the annular plane of the opening part of the telescopic capsule 5 is tightly pressed on the corresponding annular plane on the left side of the sealing flange 2, and the pressure ring 3 is arranged on the opening part of the telescopic capsule 5 The inner surface of the annular surface, the pressure ring 4 is pressed against the pressure ring 3. During the assembly process, the pressure ring 4 is tightened and fixed, so that the sealing connection between the sealing flange 2 and the telescopic capsule 5 is firm and reliable. The inner chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com