Automatic master assembling device and method with computer control

An automatic assembly, computer technology, applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of missing pieces, low labor efficiency, mismatch between car keys and car lock cylinders, etc., to achieve stable quality, reasonable structure, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

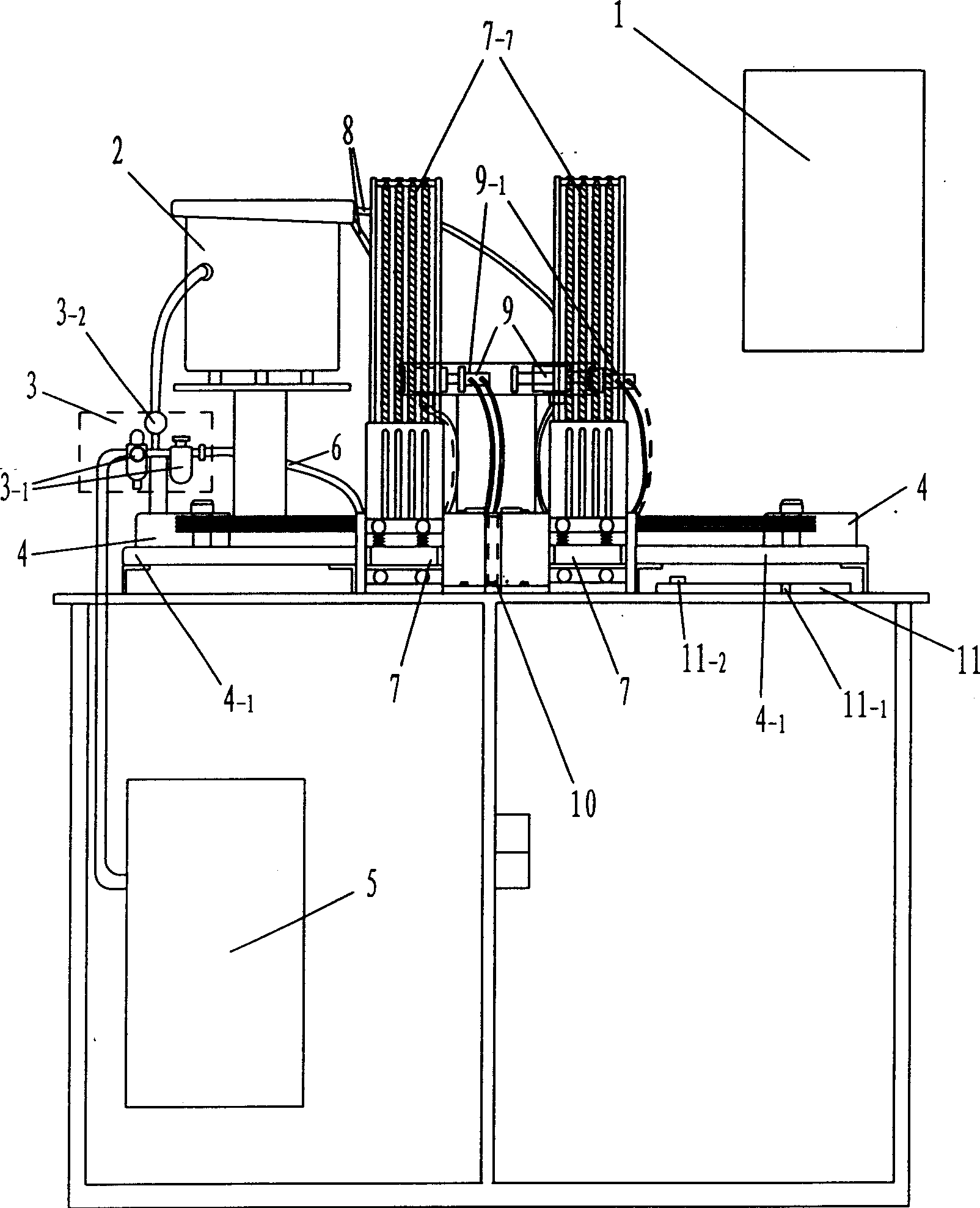

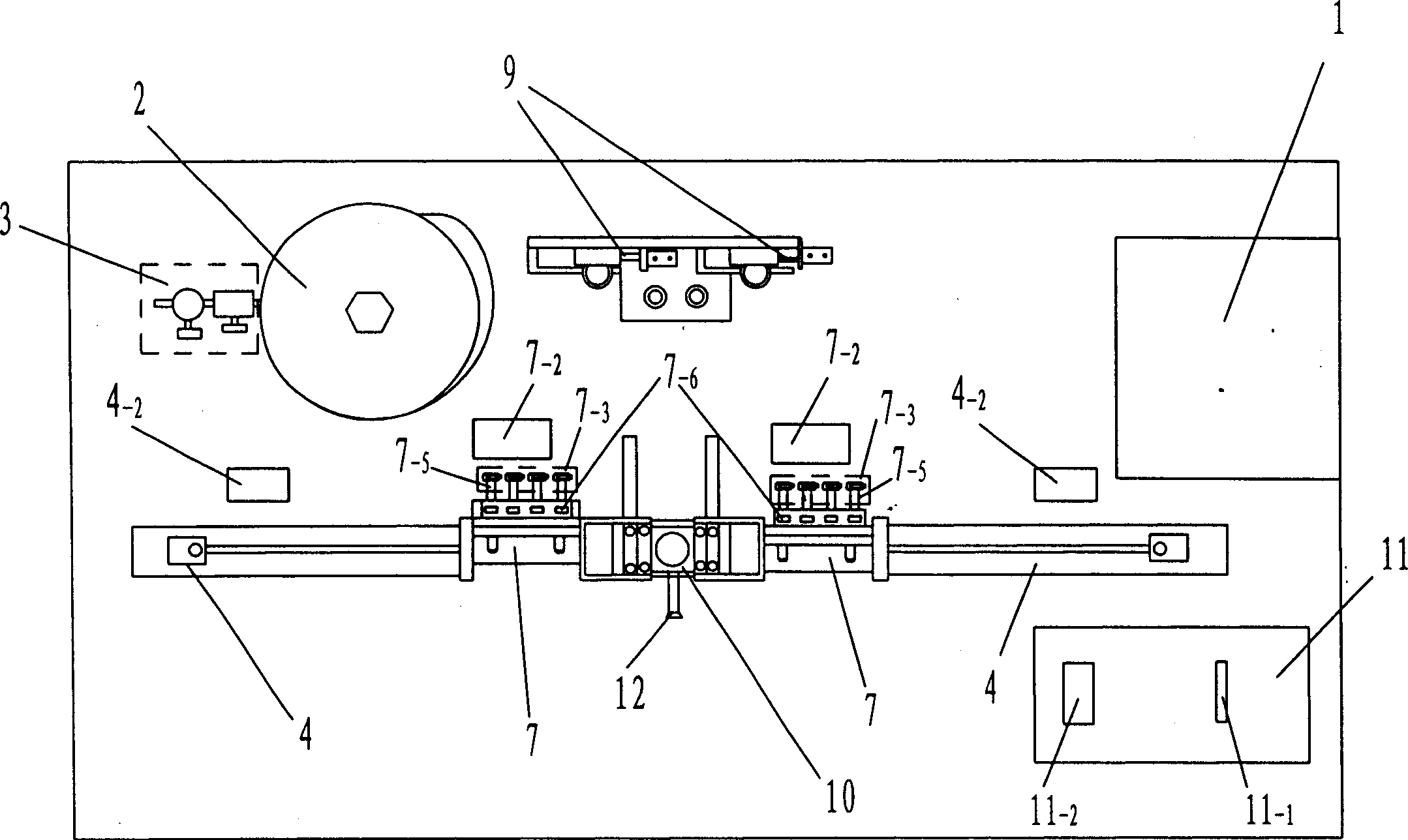

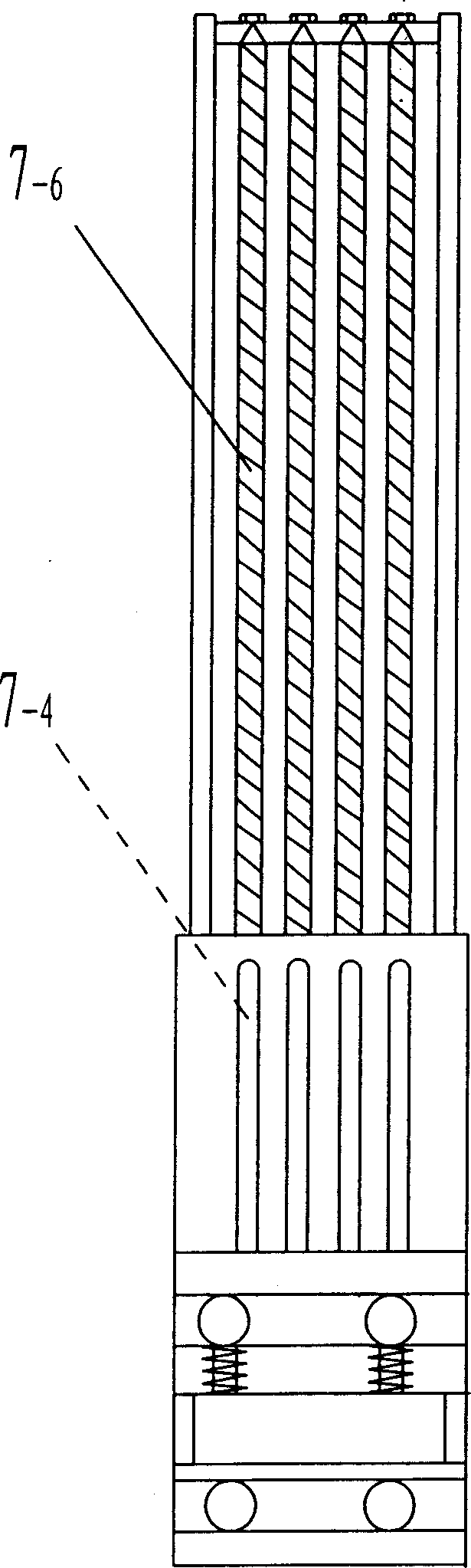

[0022] The following examples illustrate the present invention. see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , the embodiment of the present invention with computer-controlled lock core automatic assembly and assembly machine includes a computer controller 1, a vibrating plate 2, a propulsion mechanism 4, a lock plate arrangement mechanism 7, a connecting pipe 8, a spring distribution mechanism 9, a lock cylinder frame 10, Tooth shape recognition mechanism 11 and handle 12, computer controller 1 is connected with tooth shape recognition mechanism 11, vibrating plate 2 is connected with spring distribution mechanism 9 through connecting pipe 8, propulsion mechanism 4 is connected with lock plate arrangement mechanism 7, lock plate arrangement mechanism 7 is connected with the lock cylinder frame 9, the handle 12 is installed on the lock cylinder frame 9, and the tooth shape recognition mechanism 11 is provided with a recognition groove 11 -1 , c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com