Inspector for surface deficiency of silicon sheet with scattered light intensity doubling system

A silicon wafer surface, scattered light technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of insufficient concentration of scattered signals, influence, unfavorable collection of scattered light, etc., and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

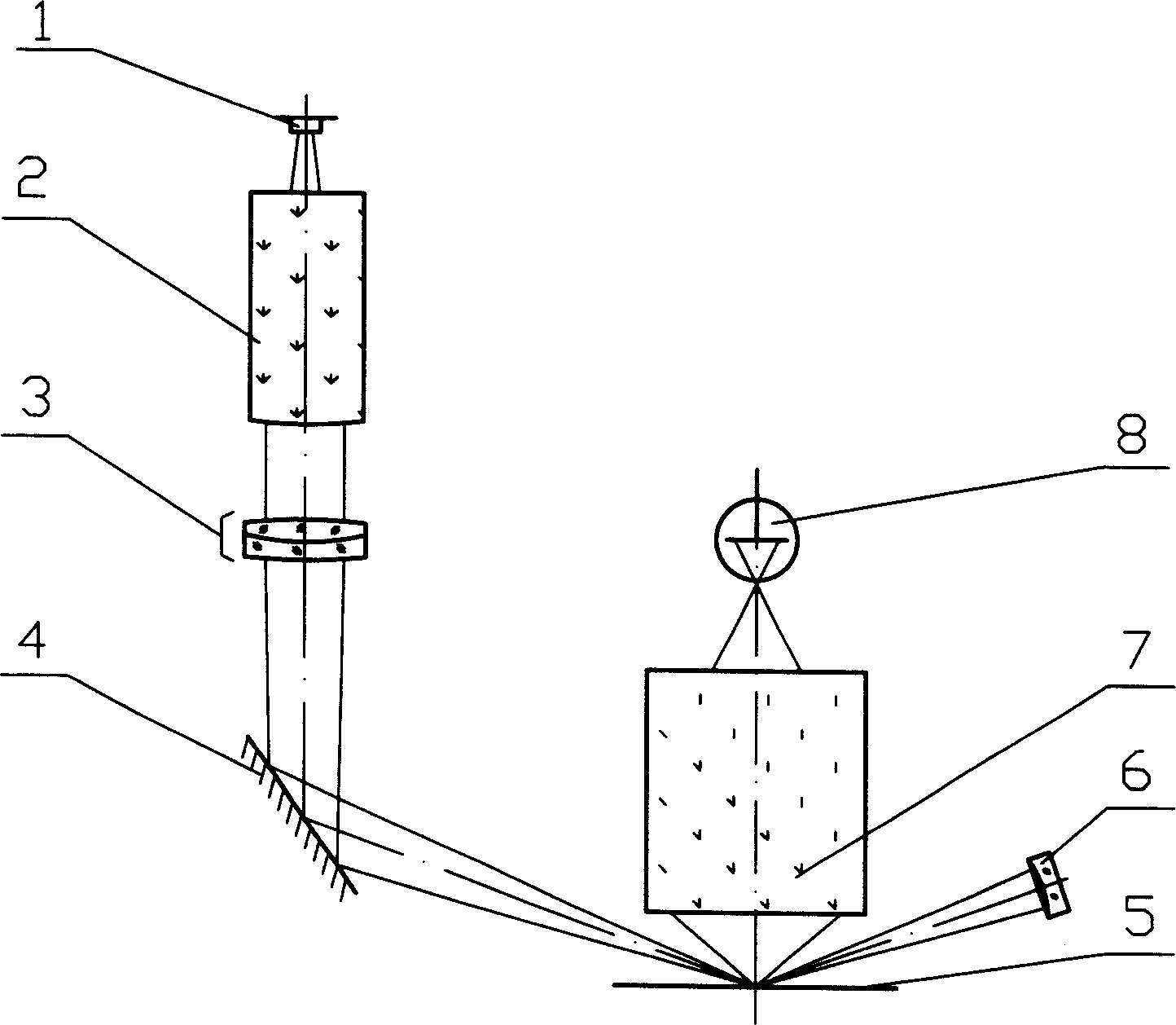

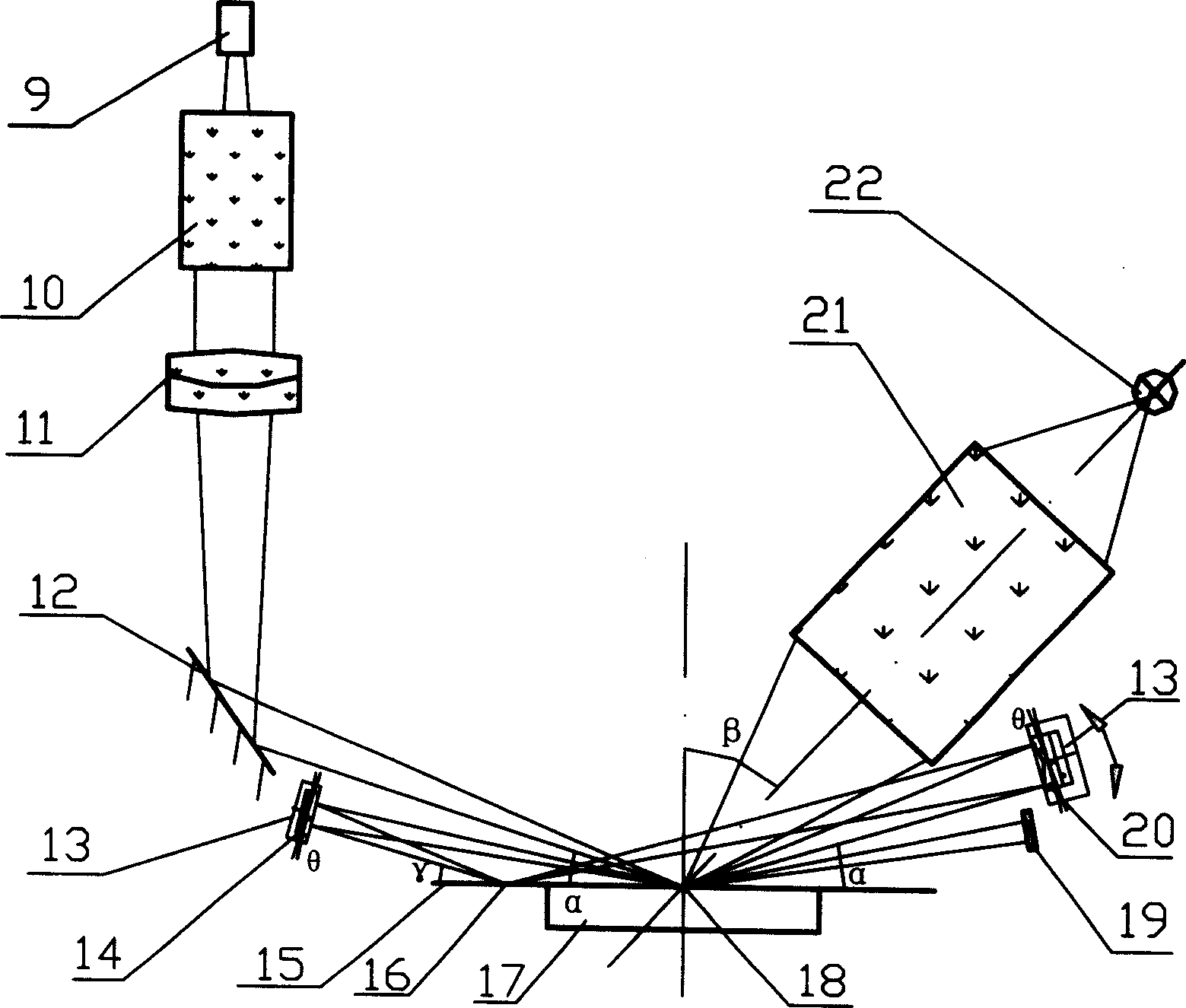

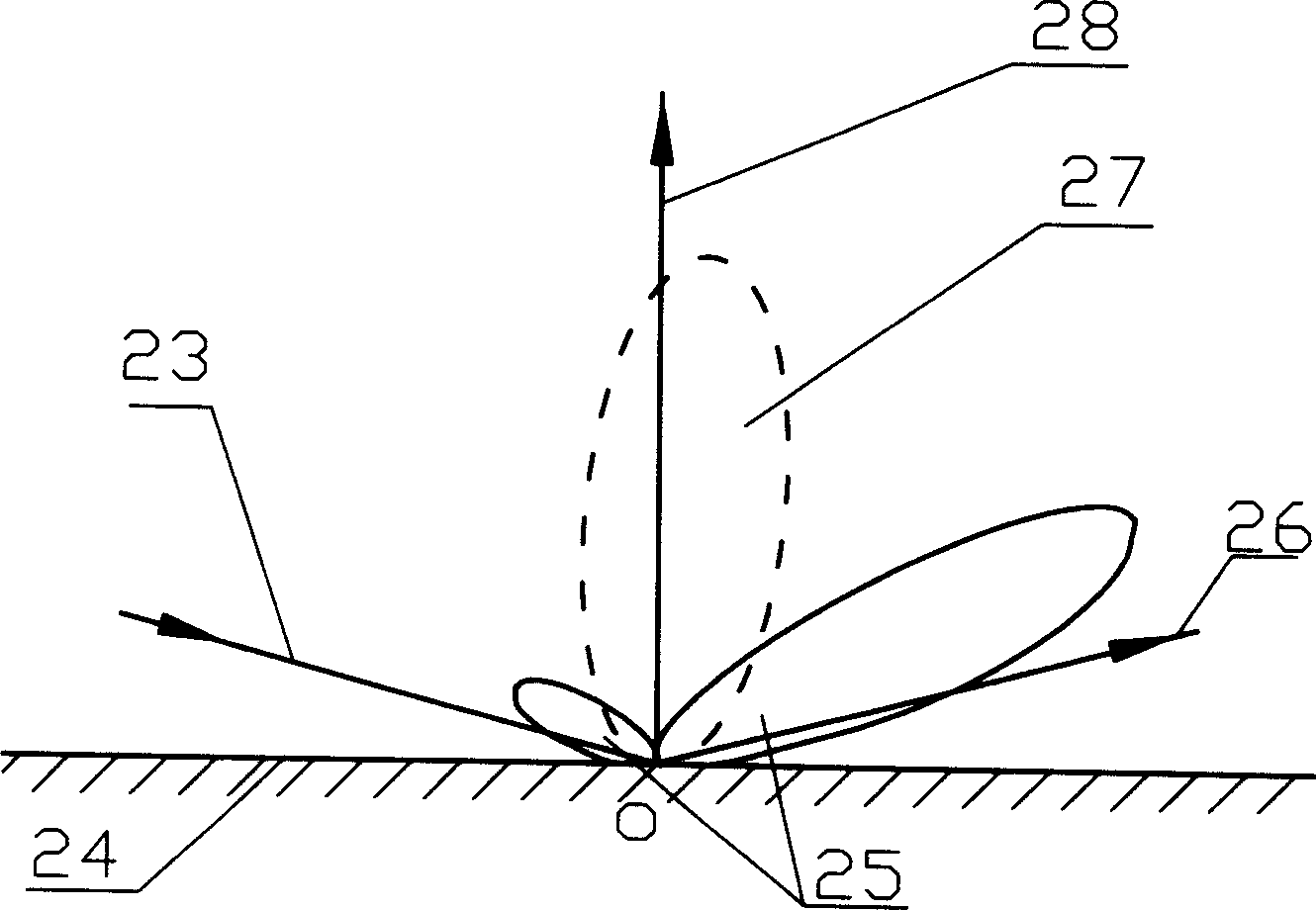

[0022] The present invention is described in detail below in conjunction with accompanying drawing.

[0023] see first figure 2 , figure 2 It is a schematic diagram of the system of the present invention. As can be seen from the figure, the present invention has a silicon wafer surface defect detector with a scattered light intensity multiplication system, including a laser incident system and a defect scattered light collection system. The laser incident system consists of a laser 9, a beam expander system 10, a focusing mirror 11 and Plane reflector 12 is formed, and described defective scattered light collection system is made up of a condenser lens group 21 and is positioned at the focus position photodetector 22 of this condenser lens group 21, is characterized in that also has:

[0024] 1. The scattered light intensity multiplication system is made up of the first spherical reflector 20 and the second spherical reflector 14, and its positional relationship is: the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com