Bolted collector for vapor liquid contacting vessel

A collector, liquid technology, applied in the direction of gas/vapor and liquid mixing, liquefaction, distillation separation, etc., can solve the problems of expensive installation, liquid leakage, time-consuming and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

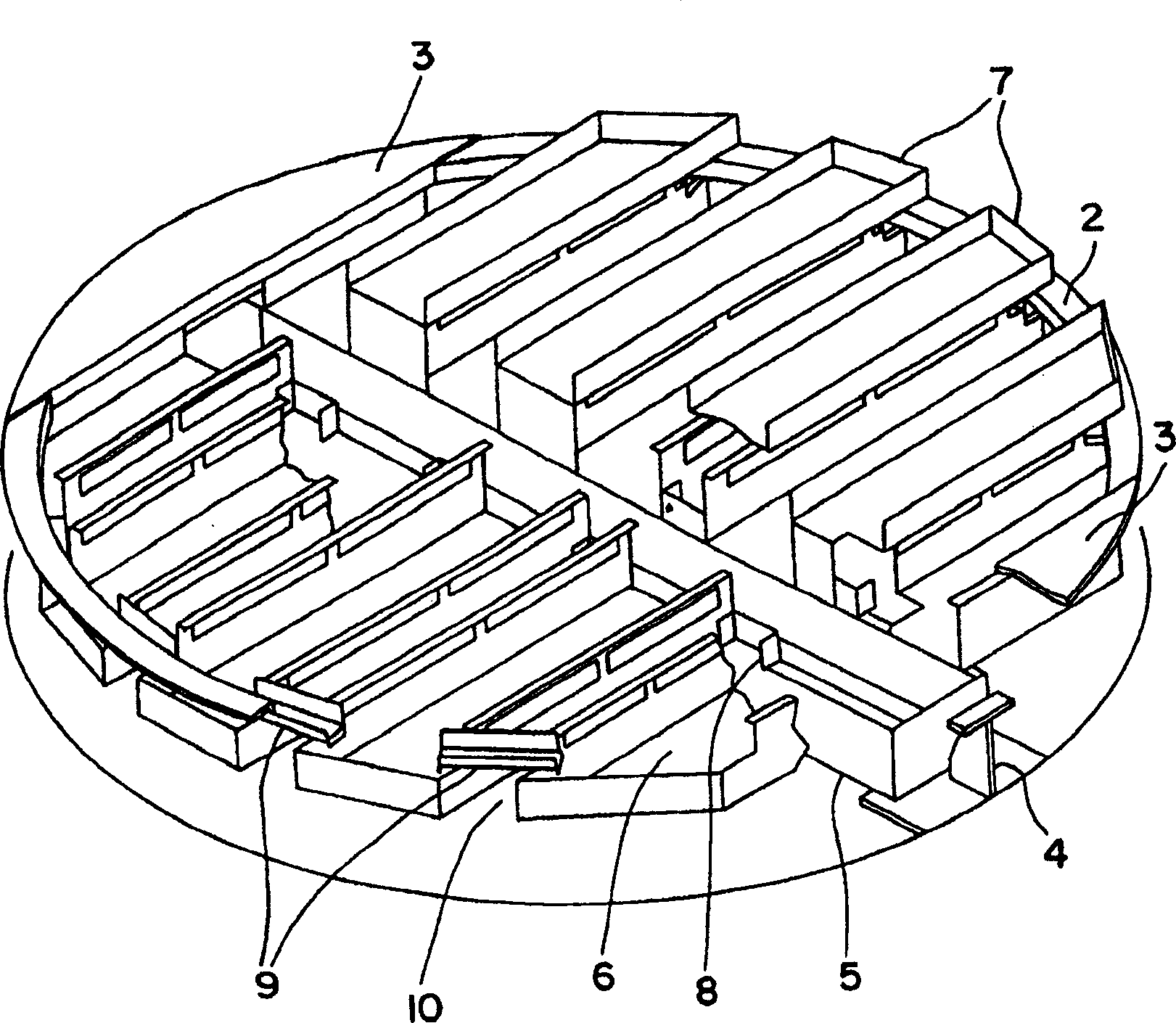

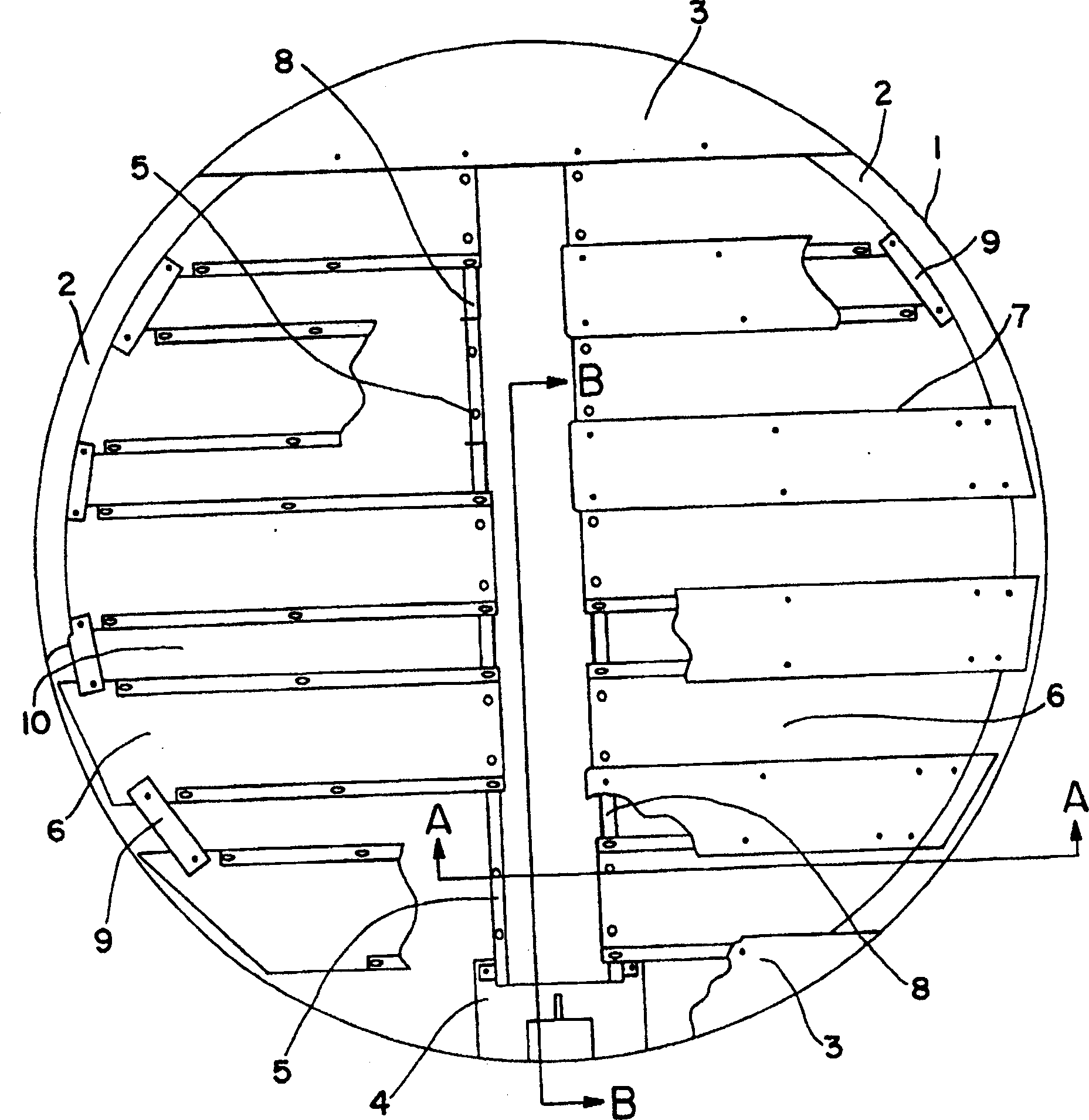

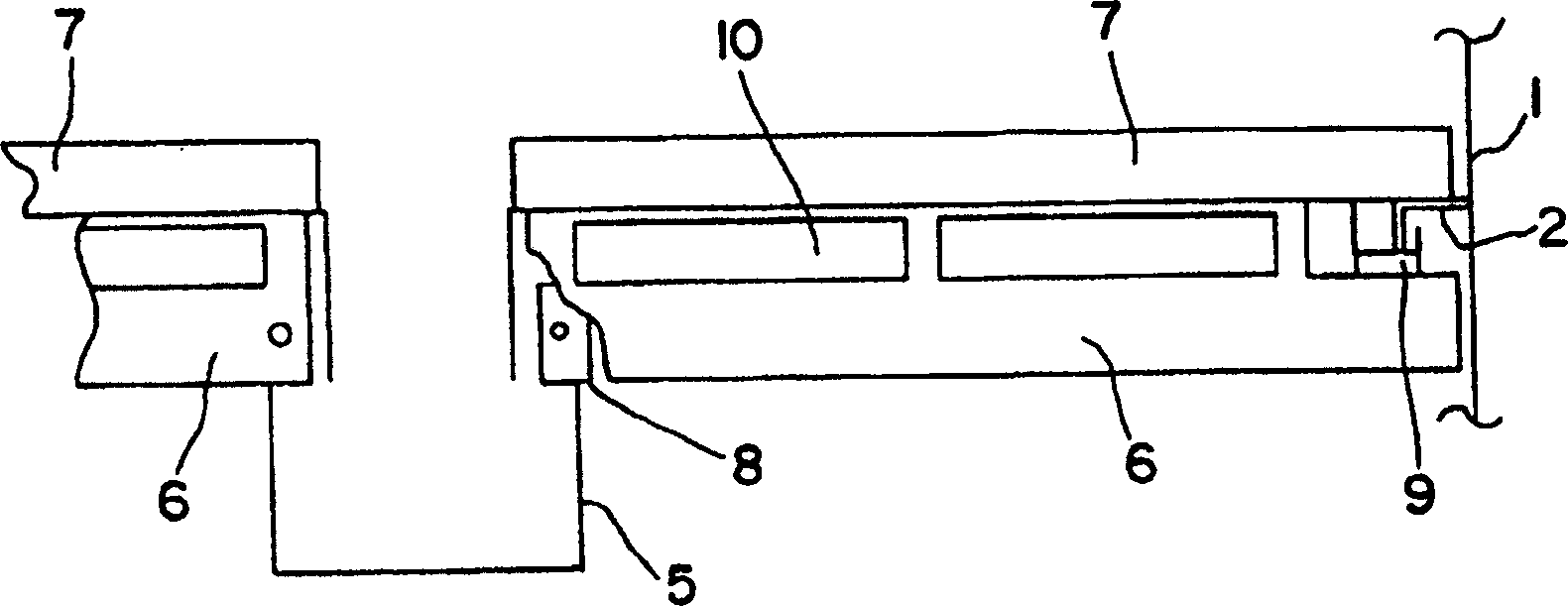

[0019] The present invention is a liquid collector that is preferably assembled using bolting rather than welding. The novel design of the present invention makes it possible to use bolts instead of sealing welds for connections, while avoiding the problems caused by the use of bolts instead of sealing welds under vapor-liquid contact heat transfer and / or mass transfer conditions, especially in Liquid loss caused by leakage under high-pressure distillation conditions during cryogenic rectification.

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings. The same reference numerals are used for the same elements. see below Figure 1-4 , The collection pan of the present invention is preferably a collection pan connected by bolts and has three overlapping levels; Arrange the levels so that any bolted joints have overlap, allowing the lower levels in the collector to catch fluid that leaks through the joints. The support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com