Method for producing thermoplastic polyurethane elastic belt and traction machine special for said method

A technology of thermoplastic polyurethane and its manufacturing method, which can be applied in the direction of belts, applications, household appliances, etc., can solve the problems of no increase in stretching action, inability to stretch multiple times, and inconvenient processing, so as to save processing man-hours, process easily, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

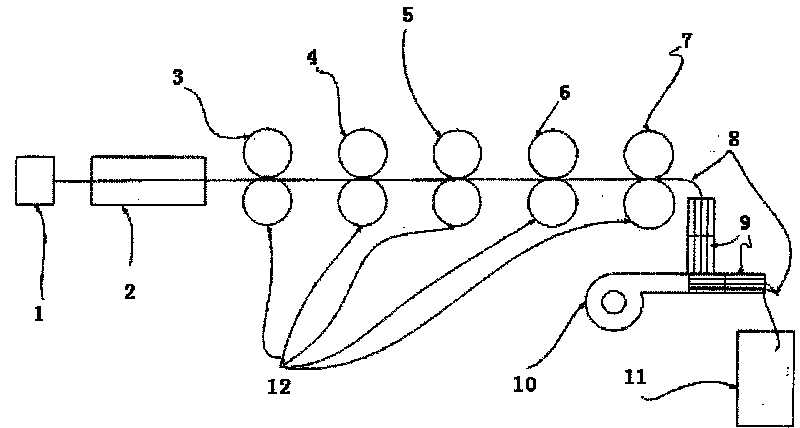

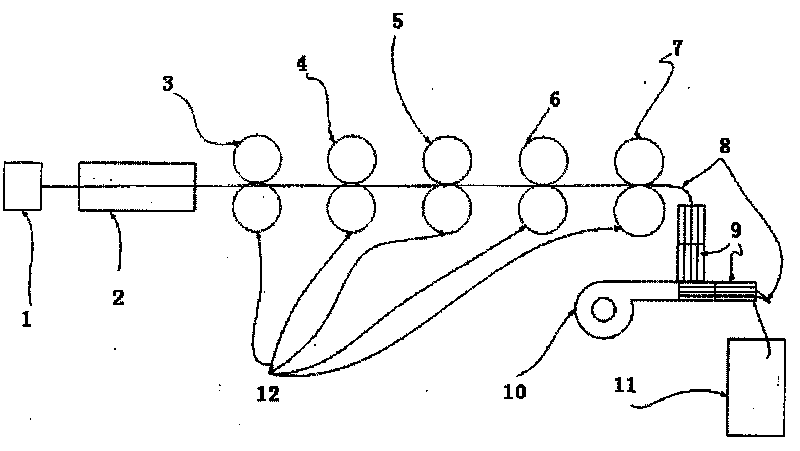

[0019] see figure 1 , the manufacture method of thermoplastic polyurethane elastomer (TPU) ultra-high elastic belt of the present invention comprises the following steps: (1) the die head 1 that thermoplastic polyurethane material is extruded with extruder; (2) extruder The extruded thermoplastic polyurethane passes through the water tank 2 to cool, and (3) the cooled thermoplastic polyurethane is drawn by the roller tractor; the roller tractor has a plurality of transmission rollers 12 below, and correspondingly has a plurality of pulling rollers above. Roller for stretching. The TPU ultra-high elastic belt extruder is cooled by the water tank, and the roller tractor passed through is multi-stage (at least three sections), and the roller tractor pulls out the TPU ultra-high elastic belt through the first roller tractor roller 3 Pull it out, go to the roller 4 of the second section of the roller tractor, and stretch it. This is the first stretching and extending action. First...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com