Production process of drop-resistant and moisture-proof color box

A production process and color box technology, applied in box making operations, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc., can solve problems such as poor drop resistance and moisture resistance, and improve wrinkle resistance. , Improve the anti-drop ability, not easy to be affected by moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

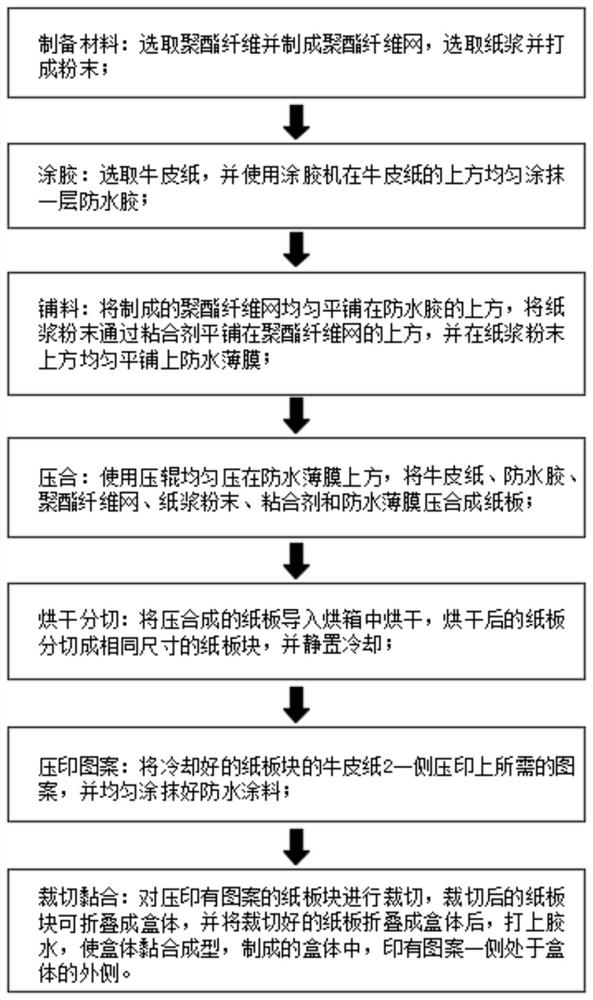

[0035] see Figure 1-4 As shown, the present invention is a production process of a drop-resistant and moisture-proof color box, comprising the following steps;

[0036] Step 1. Preparation of materials: polyester fiber is selected and made into polyester fiber web 1, pulp is selected and made into powder; polyester fiber has strong anti-wrinkle shape retention and good recovery, and after the formed polyester fiber web 1 is embedded in cardboard, The cardboard also has high recovery ability. After the color box made of cardboard is deformed, the polyester fiber mesh 1 has good wrinkle resistance and shape retention, which facilitates the rapid recovery of the carton and enhances the drop resistance of the carton.

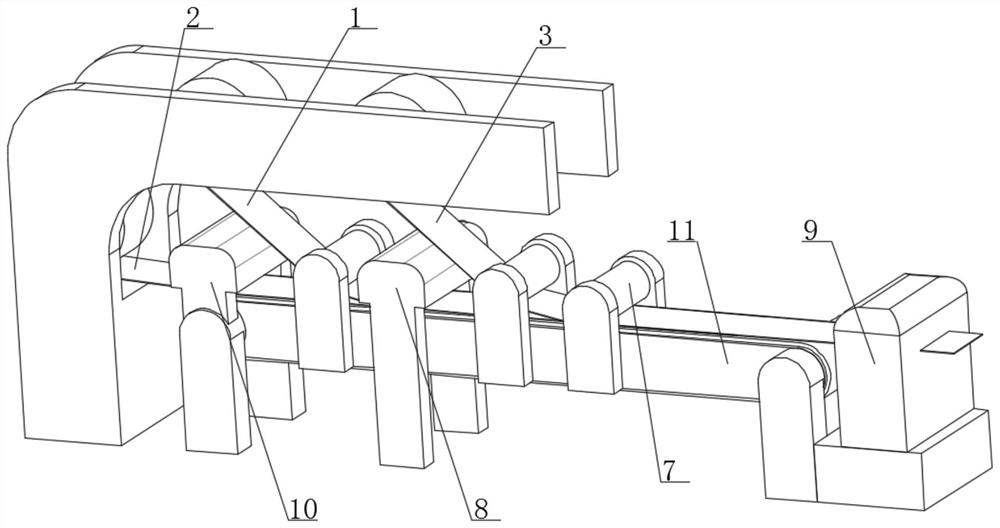

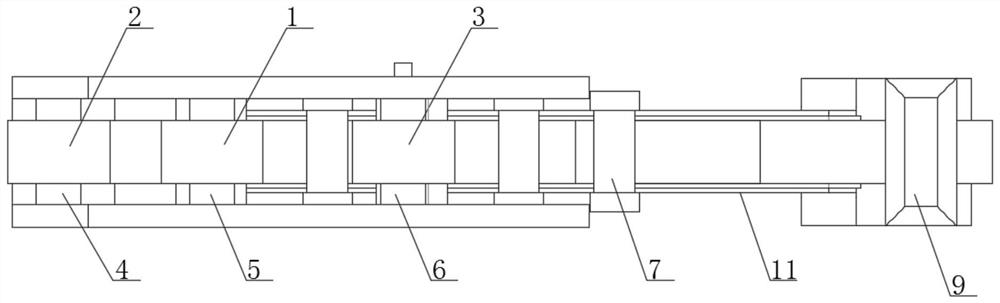

[0037] Wherein, the finished oven 9 polyester fiber web 1 has a mesh structure, and the first roller 4 is used to wind the polyester fiber web 1 together. Through the winding of the first roller 4, the storage of the polyester fiber web 1 is facilitated, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com