Rod-like lens array mfg appts and its mfg. method

A rod lens and array technology, which is applied in the field of rod lens array manufacturing devices, can solve problems such as the need to apply adhesives, increased manufacturing costs, and inability to bond and penetrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

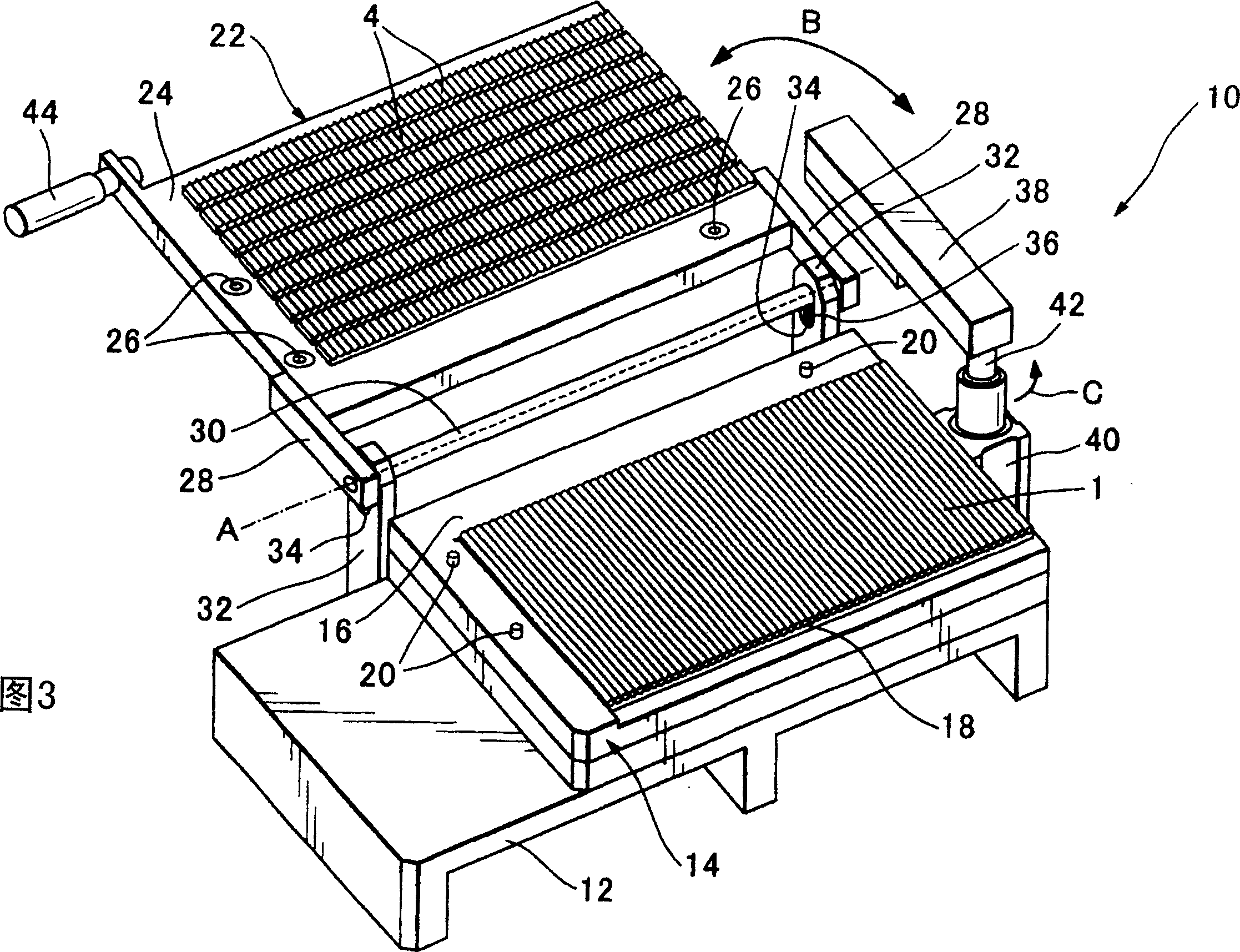

[0071] The structure of a rod lens array manufacturing apparatus according to a preferred embodiment of the present invention will be described below. The rod lens array manufacturing device according to the embodiment of the present invention includes a rod lens array bonding device, an adhesive coating device, and a rod lens array original plate cutting device.

[0072] First, the structure of the rod lens array bonding device 10 of the present embodiment will be described. FIG. 3 is a schematic perspective view of the rod lens array bonding device 10 .

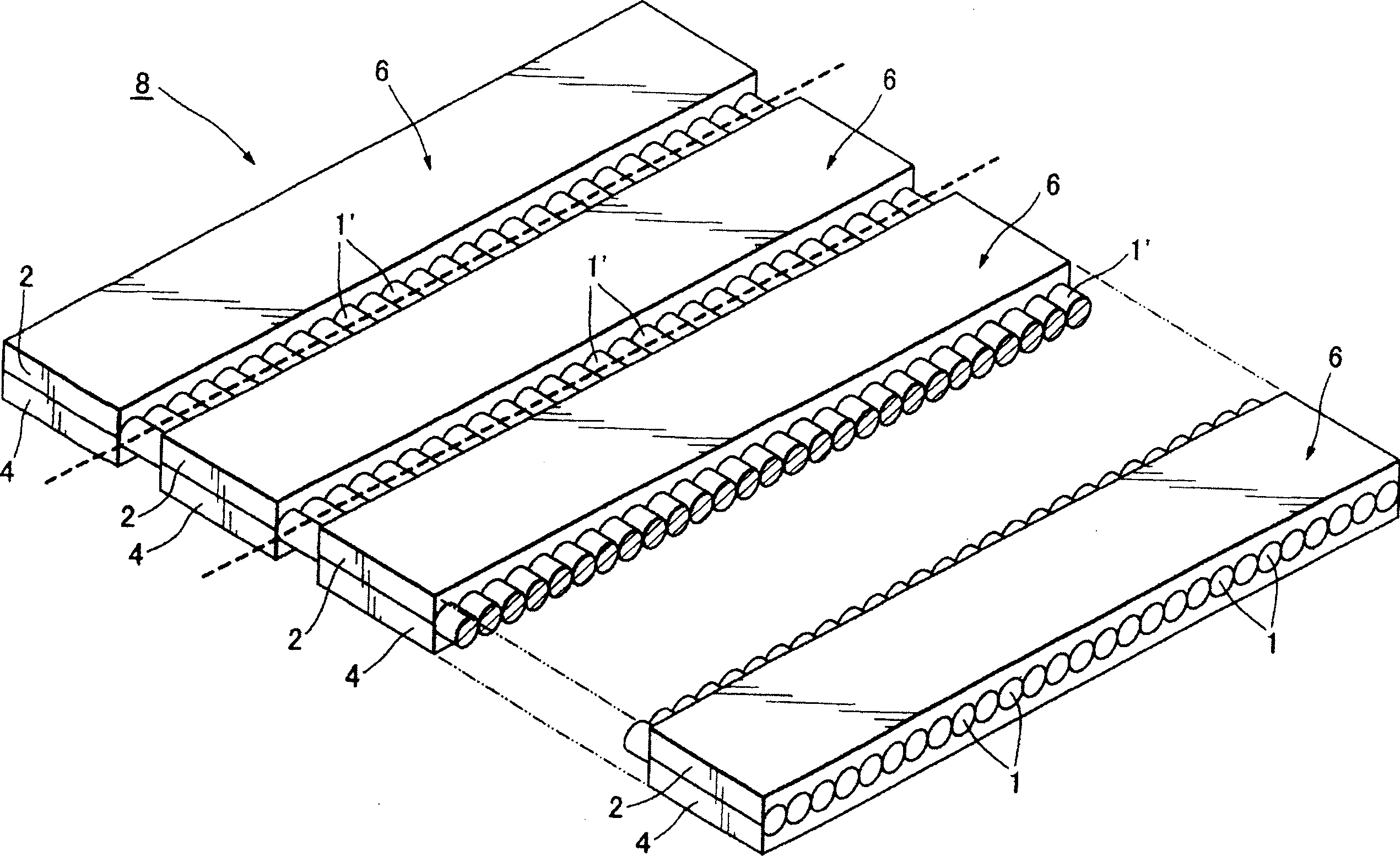

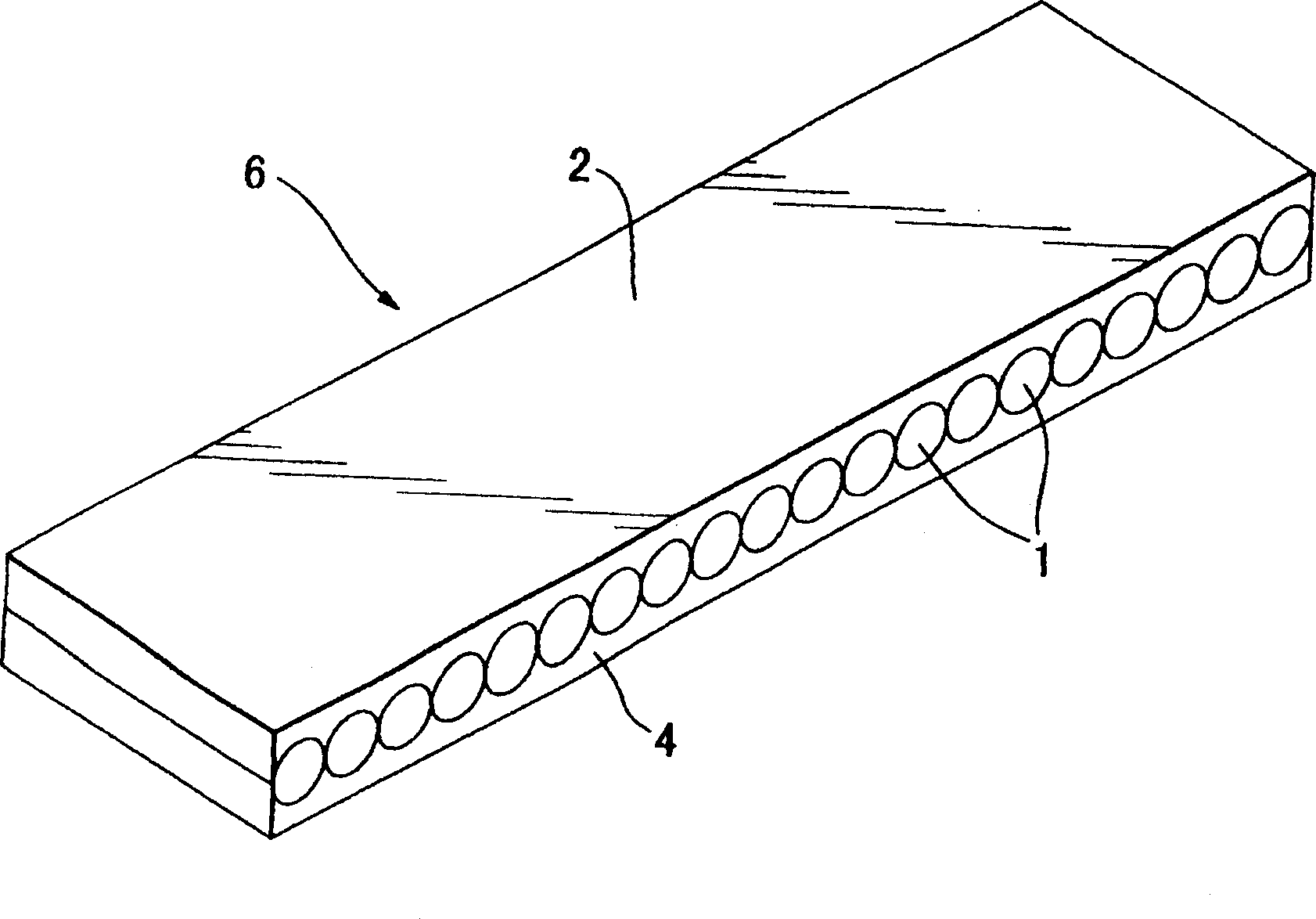

[0073] The rod lens array bonding device 10 of the present embodiment manufactures the rod lens array original plate 8 ( figure 1 )installation. Rod lens array former plate 8 is to manufacture rod lens array 6 ( figure 2 ) as an intermediate product in the process.

[0074] The rod lens array original plate 8 is configured such that a plurality of rod lenses 1 arranged in parallel penetrates between pairs of first subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com