Indigo knitted cowbog moisture sweat absorbing cloth and its manufacturing method

A technology for knitting denim and indigo blue, applied in the directions of knitting, weft knitting, textile and papermaking, etc., can solve the problems of unsatisfactory moisture absorption effect, wet and cold feeling and stickiness of fabrics, and achieve stable elasticity, high moisture absorption rate and soft hand feeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

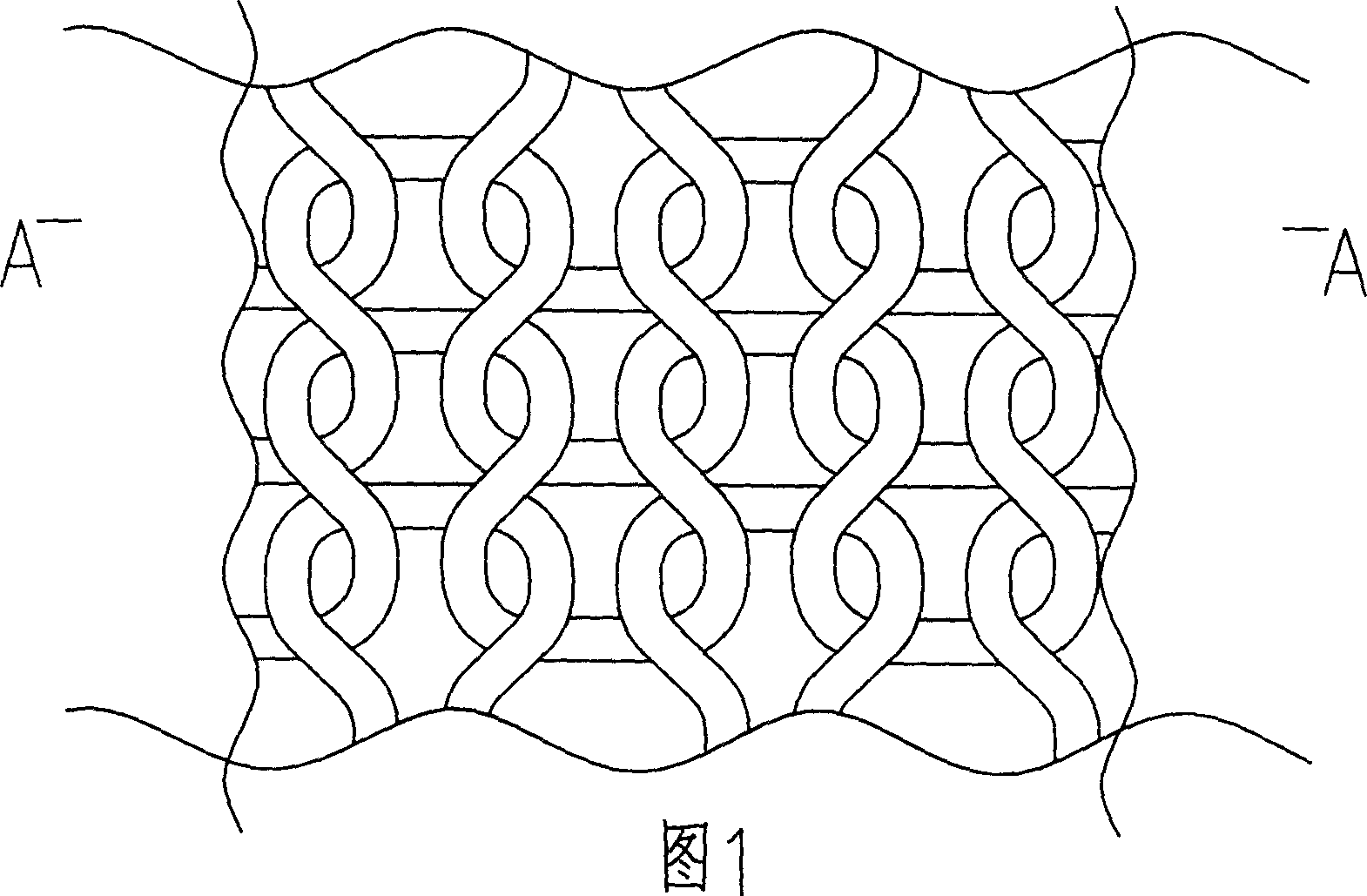

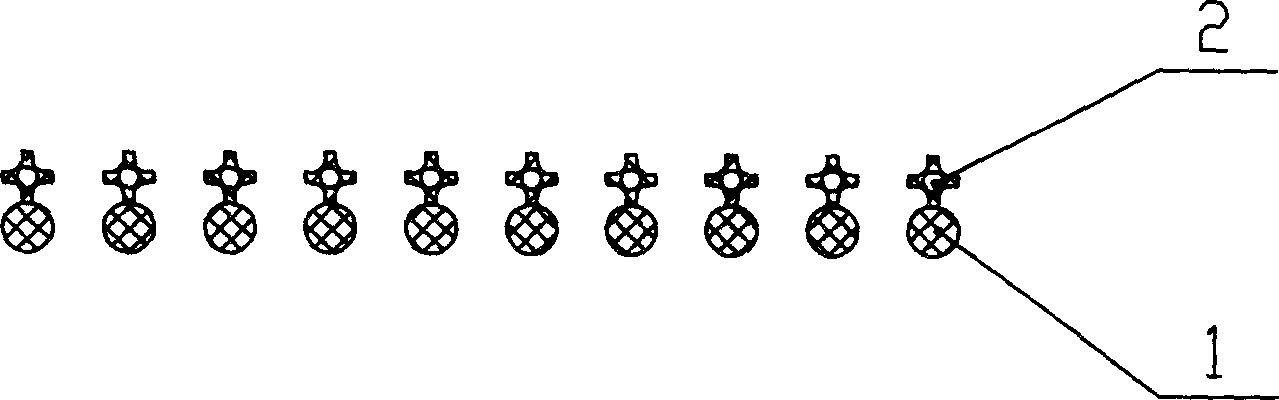

[0017] The indigo knitting denim moisture-absorbing jersey of the present invention as shown in Figure 1 is a double-sided fabric formed by weft knitting of 323 indigo pure cotton veil 1 and high moisture permeability polyester bottom yarn 2, and the surface is made of indigo pure cotton The indigo knitted denim hygroscopic layer composed of the veil 1, the colorless moisture-conducting layer composed of the high moisture-permeable polyester bottom yarn 2 on the bottom surface, and the high-moisture-conductive polyester bottom yarn 2 is four-pipe special-shaped polyester fiber (Coolmax) 75D / F45.

[0018] The preparation method of the indigo knitting denim moisture-absorbing jersey is characterized in that it has the following process steps:

[0019] a. Yarn dyeing, first warp the pure cotton yarn, then use the dyeing machine to carry out bundle-shaped indigo reduction dyeing, then divide the warp through the warp dividing machine, and then make the indigo cheese through the bob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com