Train controlling method and controller for railway vehicle

A technology of train control and control device, applied in vehicle components, electrical program control, locomotive and other directions, can solve the problems of loss, efficiency reduction, loss of transformer core loss, etc., and achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

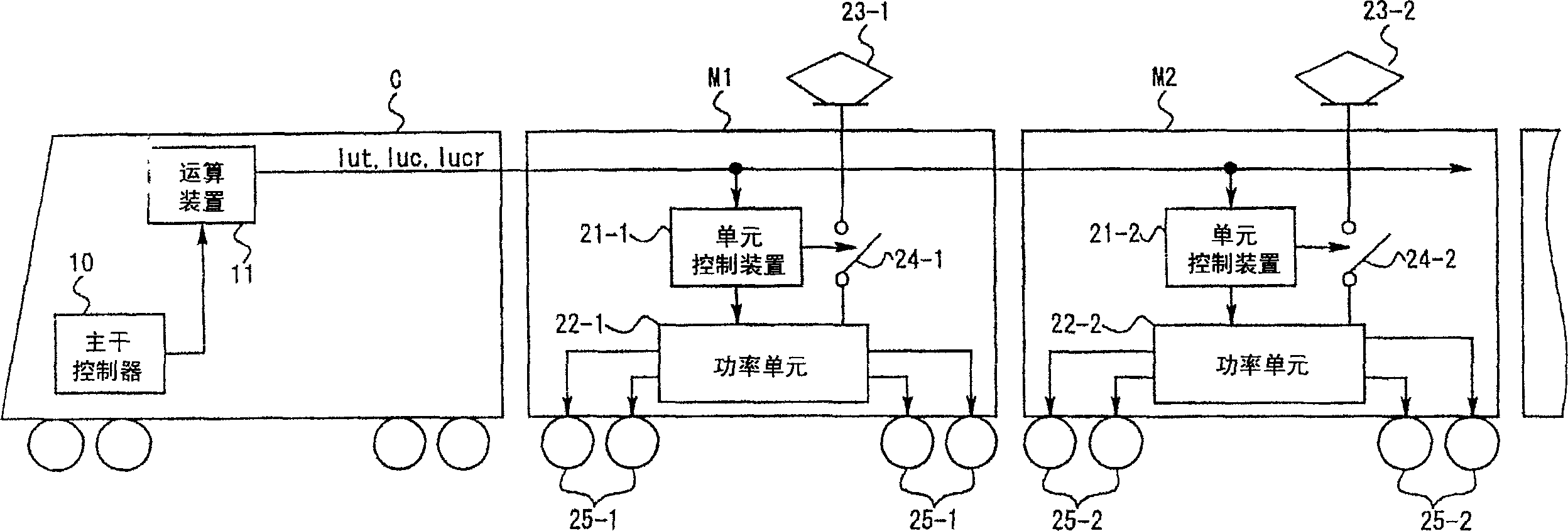

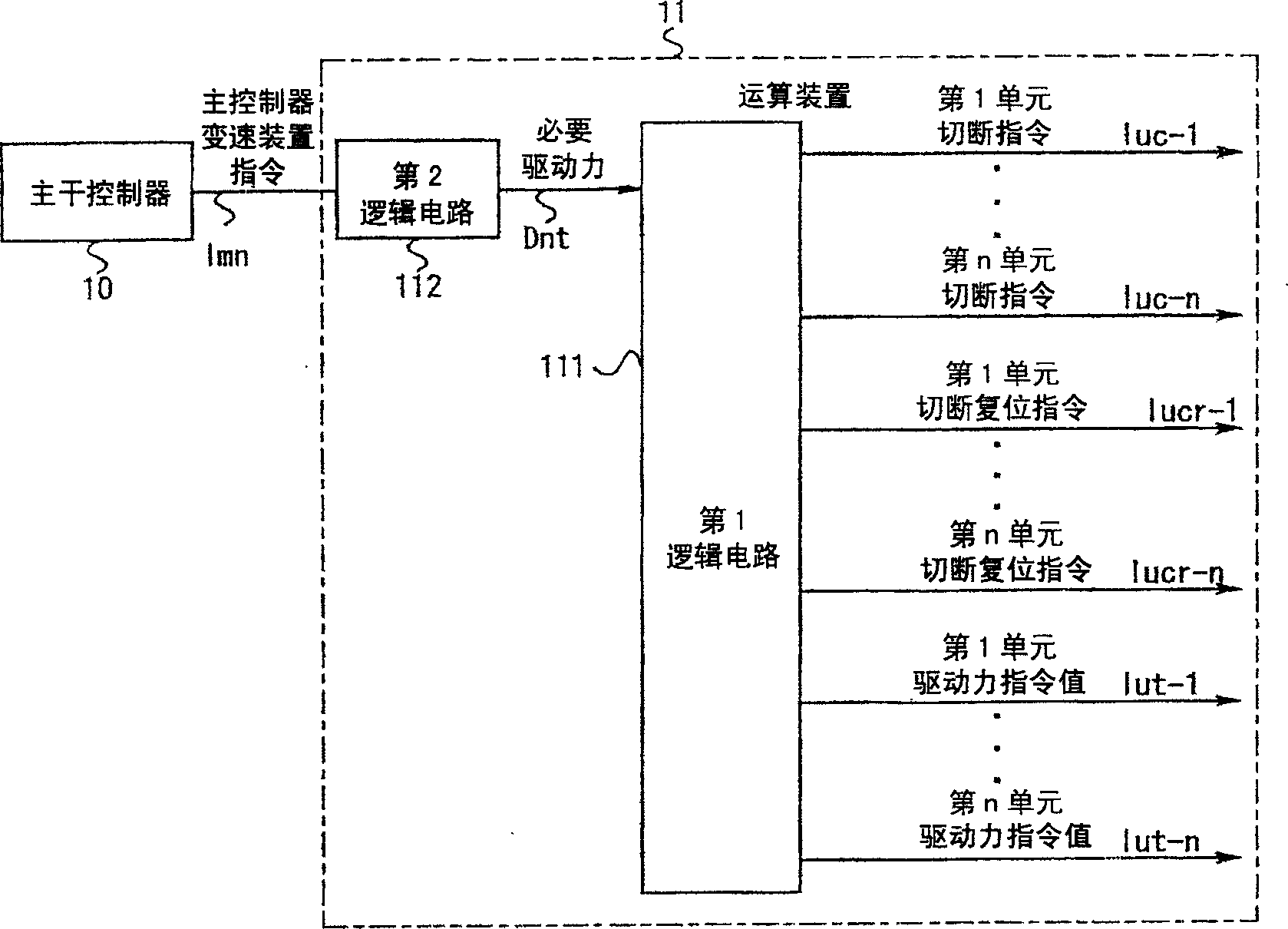

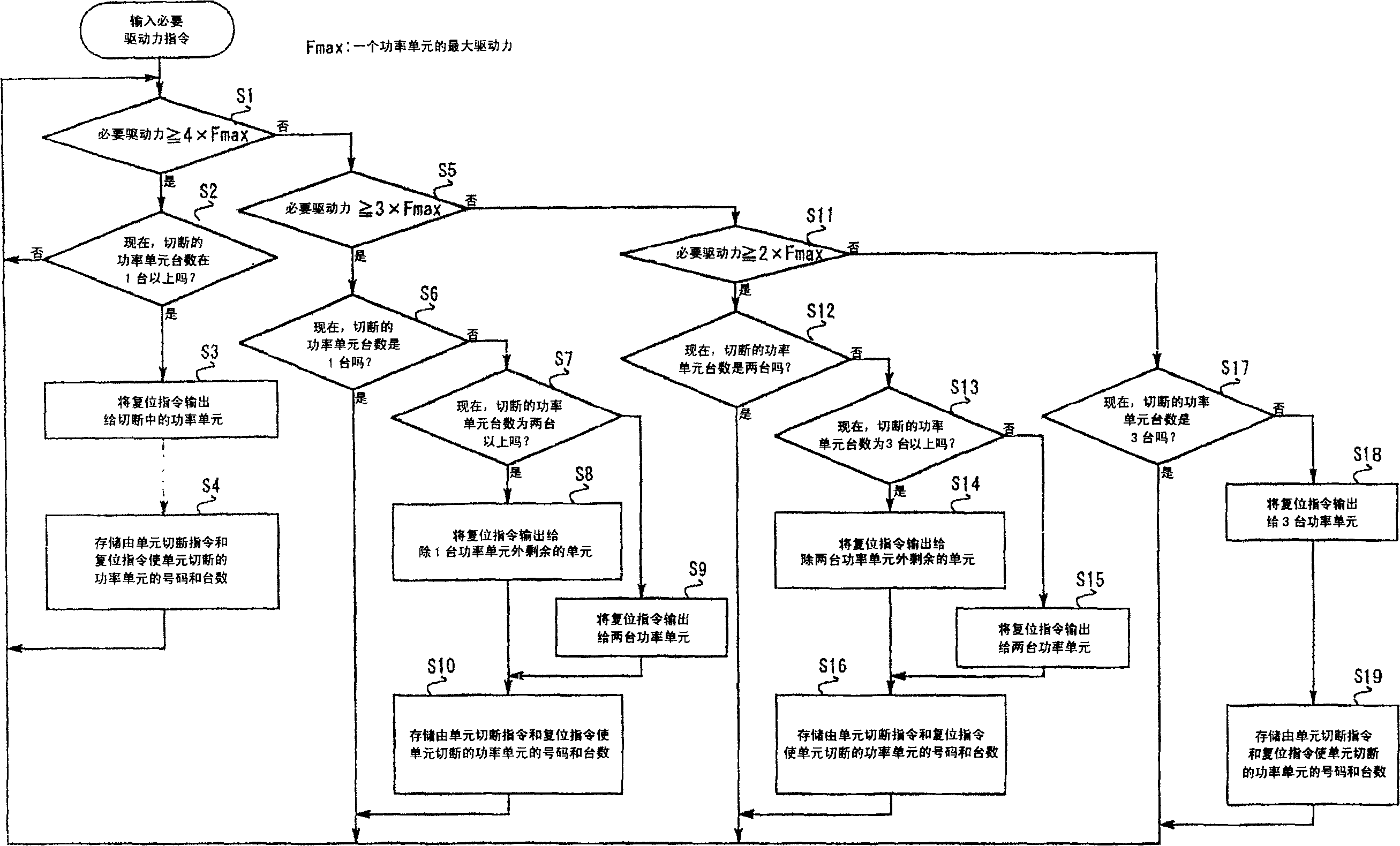

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings. use figure 1, and the main configuration of the train to which the energy-saving operation method of the railway vehicle according to the embodiment of the present invention is applied will be described. The train connects and marshals the control vehicle C with the backbone controller 10 and the computing device 11 on the workbench, and the electric vehicle M with the unit control device 21, power unit 22, power collector 23, high-voltage switch 24, and motor 25. A unit cut-off command for instructing the opening of the power unit or a unit cut-off reset command Iucr for releasing the Iuc power unit cut-off command is issued from the computing device 11 installed on a workbench or the like for controlling the vehicle C, and is sent to each unit control device 21 as the main controller. The driving force command Iut of the transmission command Imn.

[0033] Each unit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com