Reduced splattering of unpassivated laser fuses

A laser and fusing technology, applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of non-passivated fuse short circuit, fuse material splashing, etc., to reduce the overall manufacturing time and cost, easy modified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The making and using of various embodiments are described in detail below. It should be appreciated, however, that the present invention provides many applicable inventive concepts that can be embodied in many specific contexts. The specific embodiments described herein are intended merely to illustrate individual ways to make and use the invention, and are not intended to limit the scope of the invention.

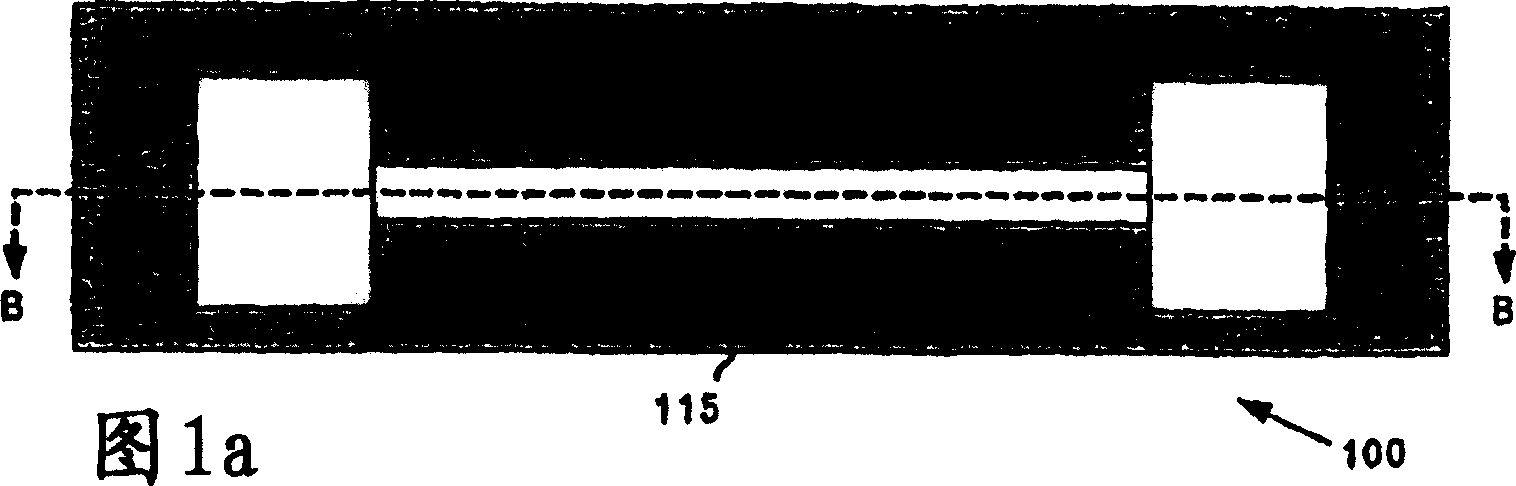

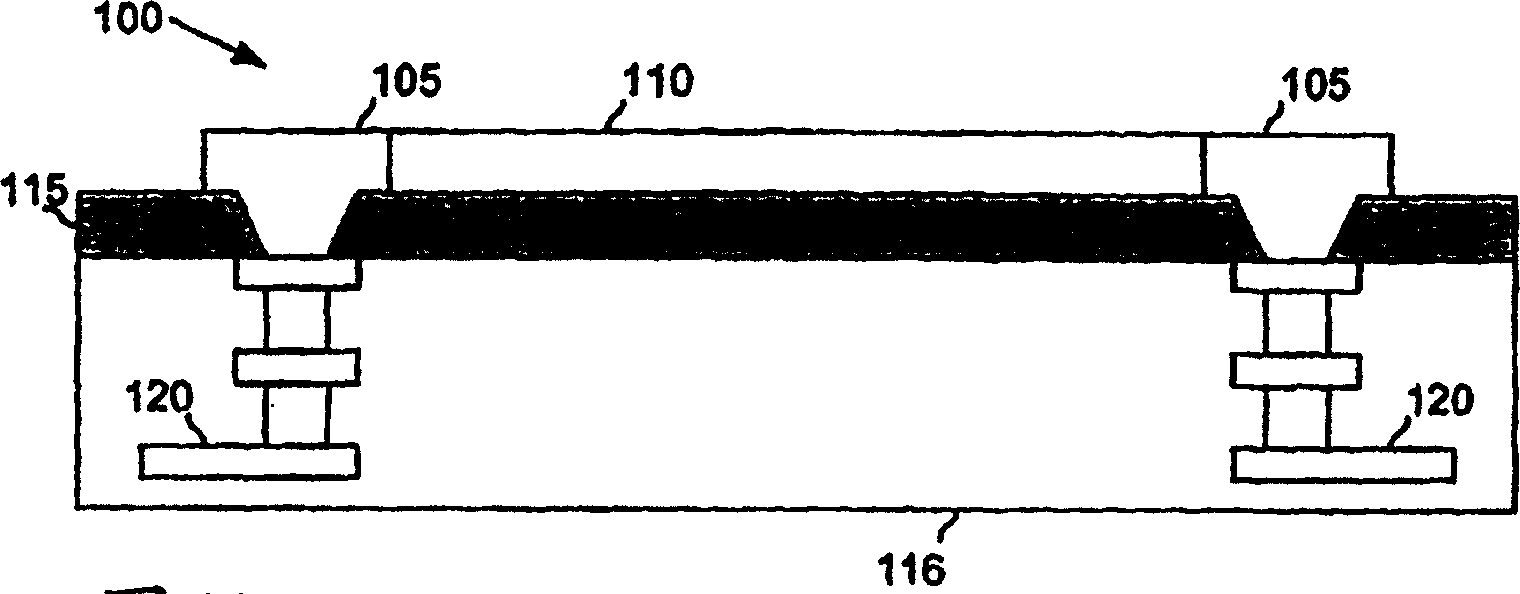

[0027] Turning now to FIG. 1 , this figure illustrates a top view of a non-passivated laser fuse 100 on a hard dielectric layer 115 . The hard dielectric layer is on top of a substrate 116 (not shown in Figure Ia, but present in cross-section later on). As mentioned earlier, a non-passivated laser fuse differs from a passivated laser fuse in that it lacks a passivation layer to protect it from the environment. A non-passivated laser fuse requires less laser energy to blow than a passivated laser fuse. This is because the laser does not have to first penetrate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com