Wheel type rotor engine

A rotor engine and rotor technology, applied in the direction of rotary piston engine, combustion engine, rotary or swing piston engine, etc., can solve the problems of unbalanced motion, high manufacturing cost, easy speeding, etc., and achieve high economy and power, Simple structure, low emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

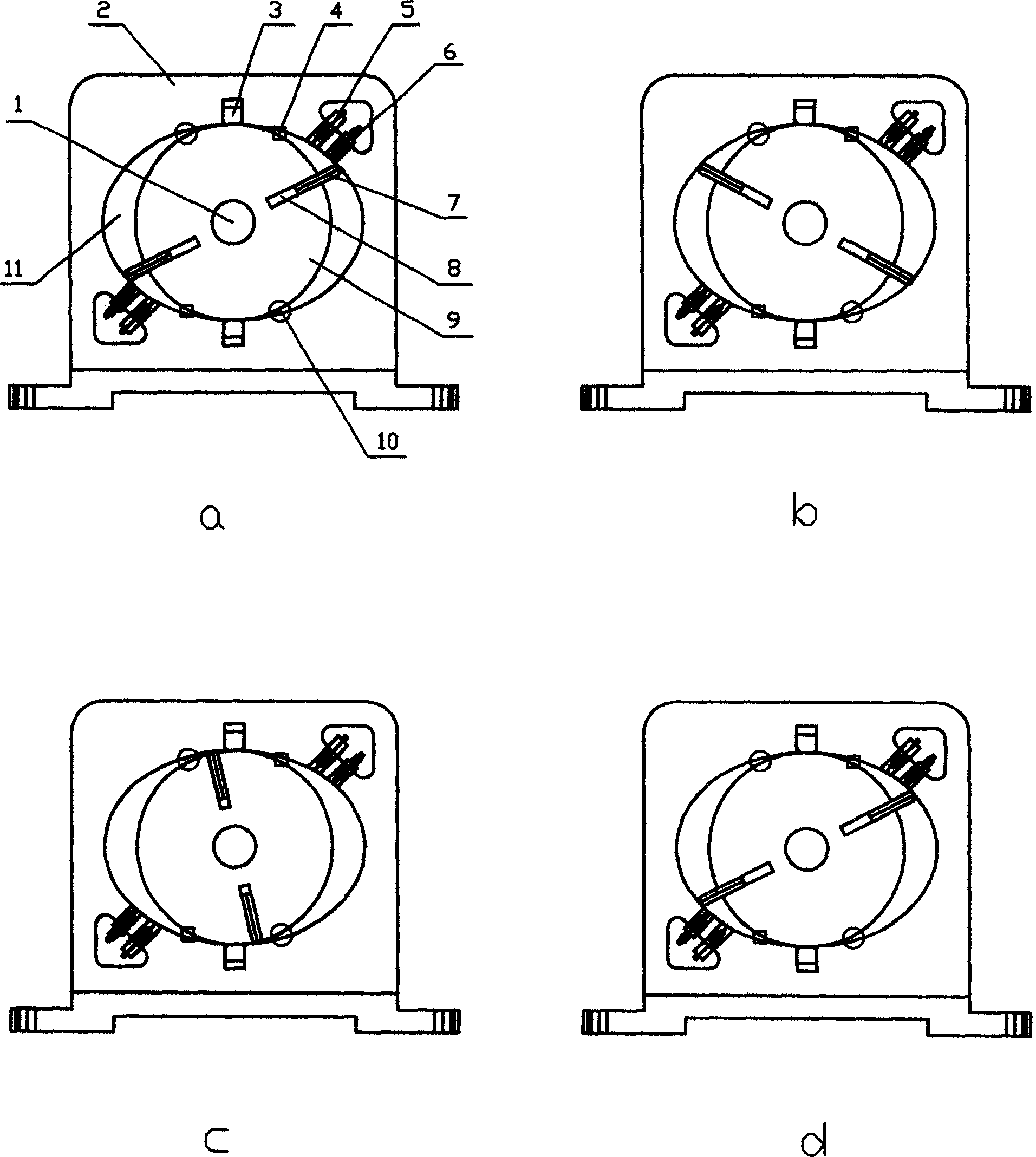

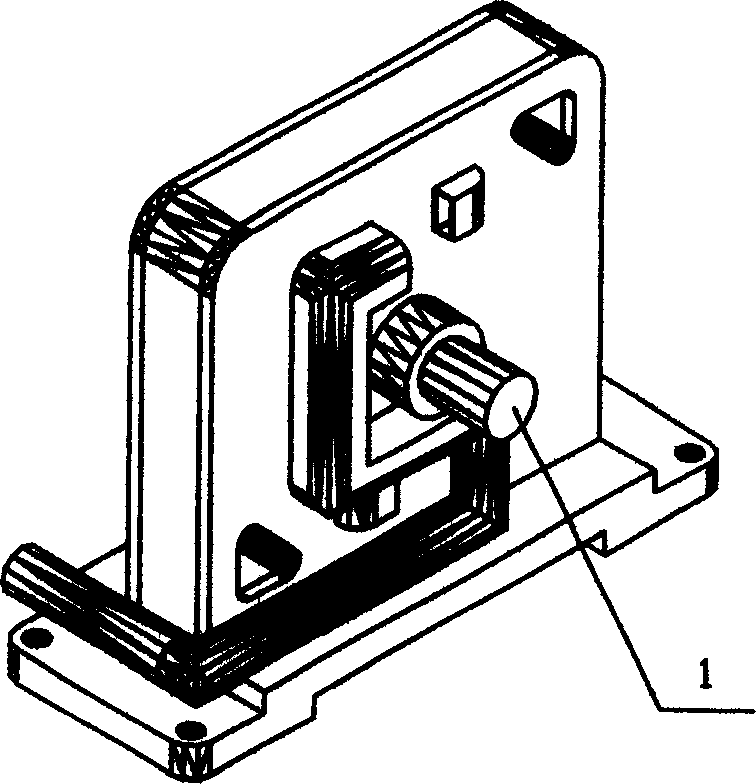

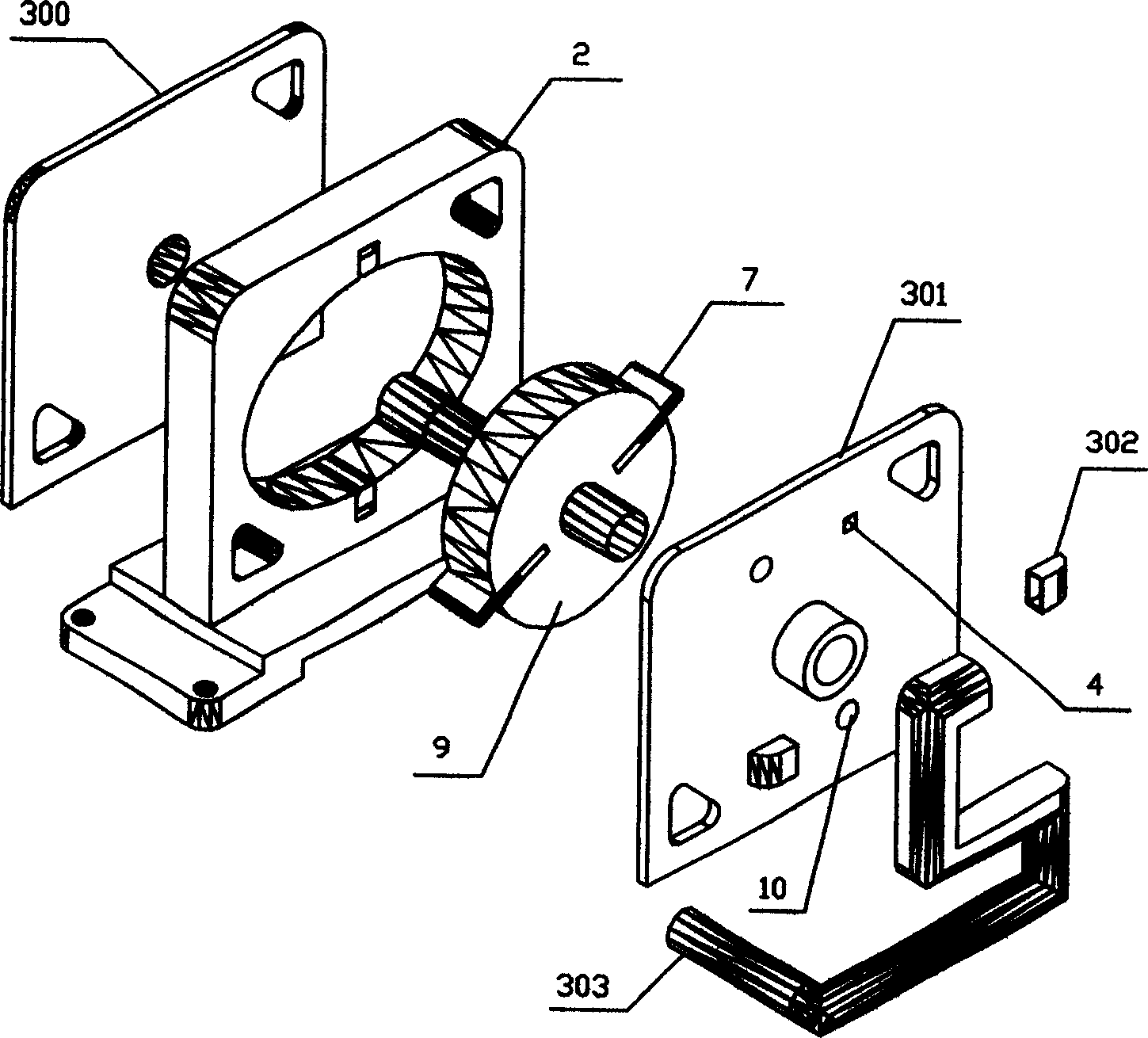

[0020] A wheeled rotor engine, the inner hole of the stator (2) is elliptical, there is a cavity (11) between the rotor (9) and the stator (2), and the cavity (11) between the rotor (9) and the stator (2) 11) There are two or more than two. Stator (2) endoporus also can be made into other shapes such as wave or curved surface, and the shape of stator (2) will be conducive to doing work, and can allow the rotating vane (7) on the rotor (9) to go through very smoothly, A power output shaft (1) is arranged on the rotor (9), and the power output shaft (1) is installed on the front end cover (301) and the rear end cover (300), and the rotor (9) forms a rotatable connection with the stator (2). Ignition mechanism can use existing technology, and ignition mechanism and rotor (9) constitute synchronous structure, and the power take-off shaft (1) of rotor (9) is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com