Clamp type doppler ultrasonic flow rate ditribution instrument

A flow velocity distribution, ultrasonic technology, applied in fluid velocity measurement, instrument, test/calibration volume flow, etc., to achieve high accuracy, eliminate offset error, and ensure interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the following, preferred embodiments of the present invention will be explained with reference to the accompanying drawings.

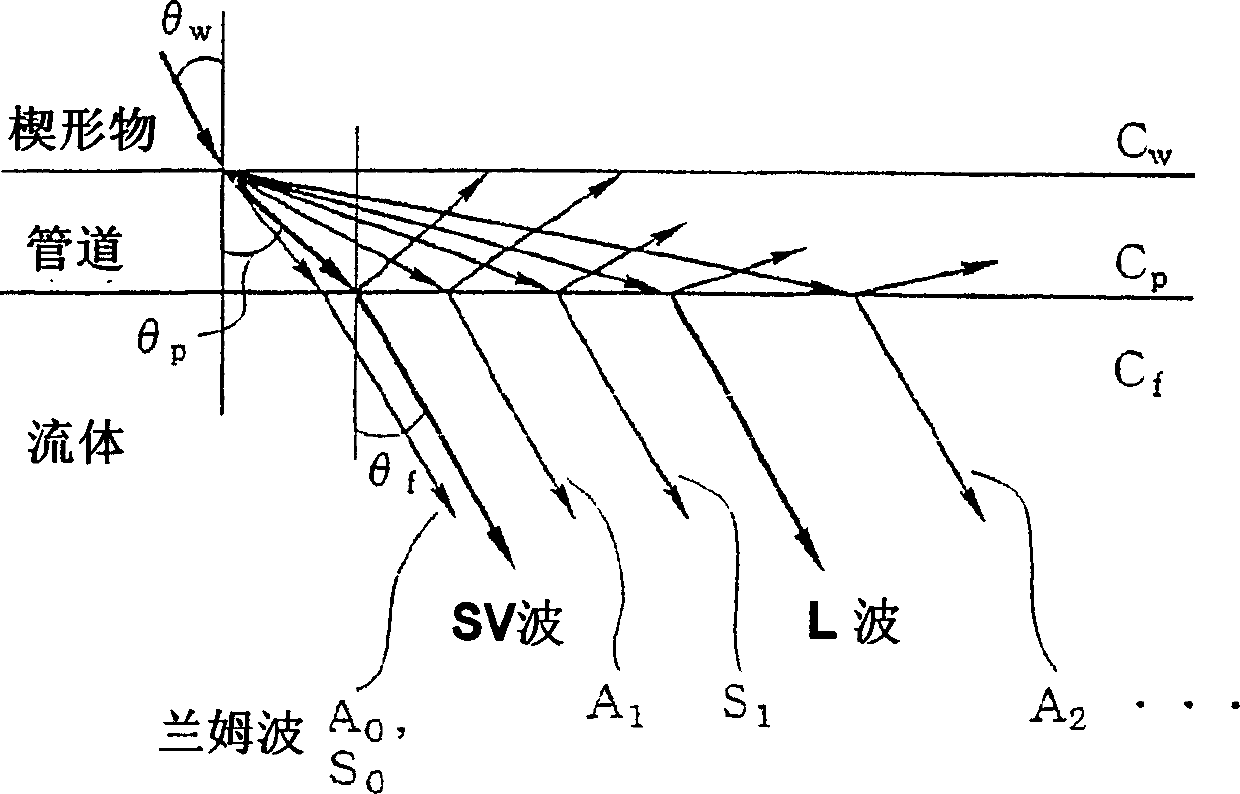

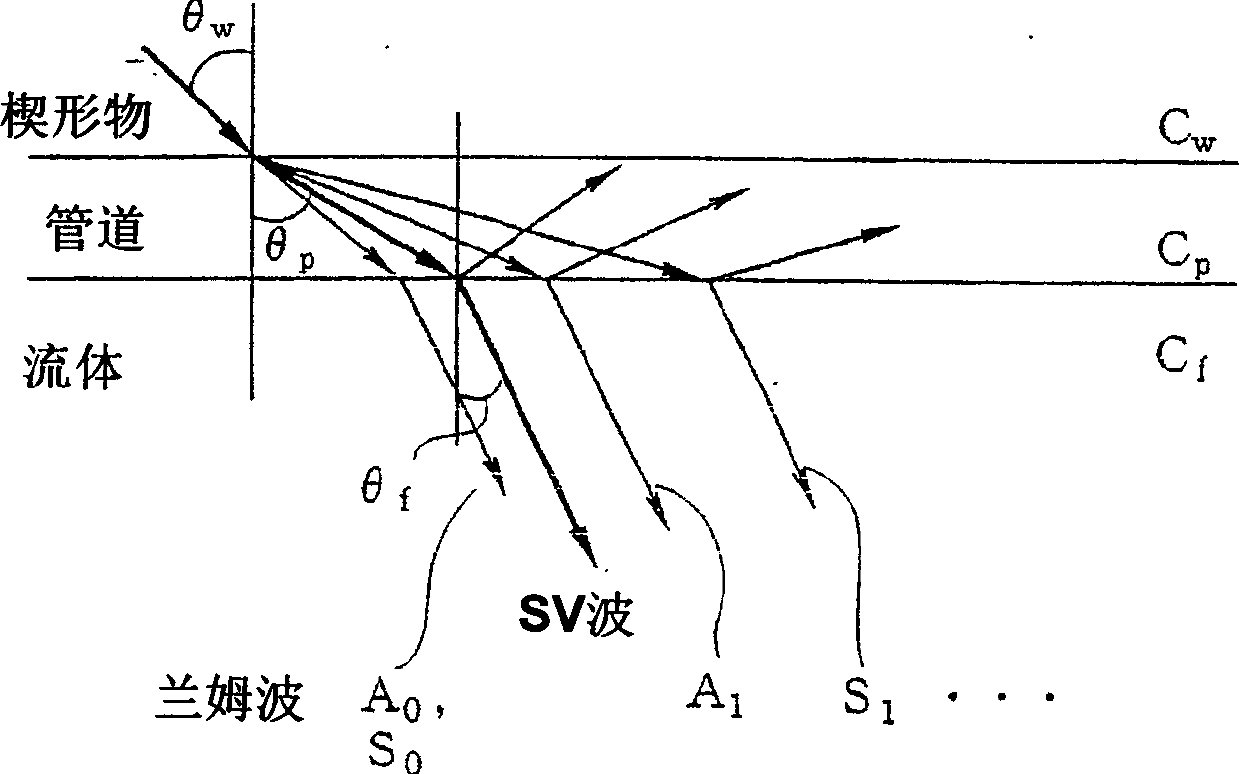

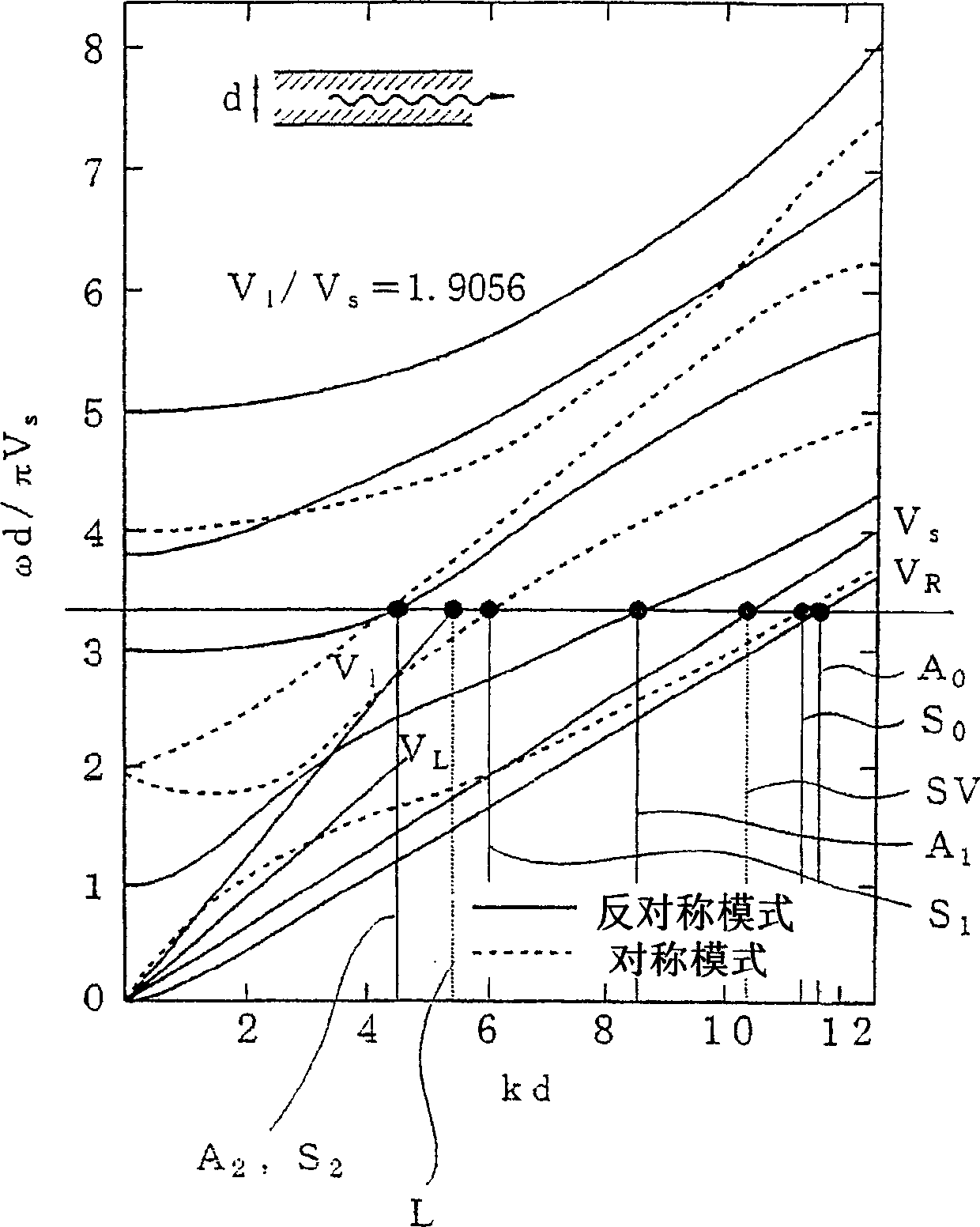

[0045] First, according to research conducted by the present inventors, the above-mentioned frequency dependence is caused by a dispersion phenomenon (a phenomenon in which the speed of sound varies depending on frequency) occurring in the pipe. It is believed that when the pipe is assumed to be a plate as thick as the plate of the pipe, this dispersion phenomenon is caused by the standard mode of the wave propagating in the plate using the plate as a waveguide. Here, each standard mode of waves in the plate is an acoustic wave with a specific frequency and a specific wavelength that satisfies the boundary conditions and propagates along a plate of finite thickness extending infinitely. The standard mode in which waves appear in a plate depends on the material and thickness of the plate.

[0046] The standard modes of waves in the plate occu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com