Parallel flat platc line-type element and circuit substrate

A parallel-plate, line-type technology, applied in circuits, electrical components, waveguide-type devices, etc., can solve the problems of reducing impedance value, difficult to low impedance, reducing internal impedance of power supply, etc., to achieve superior stability and durability, easy volume The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

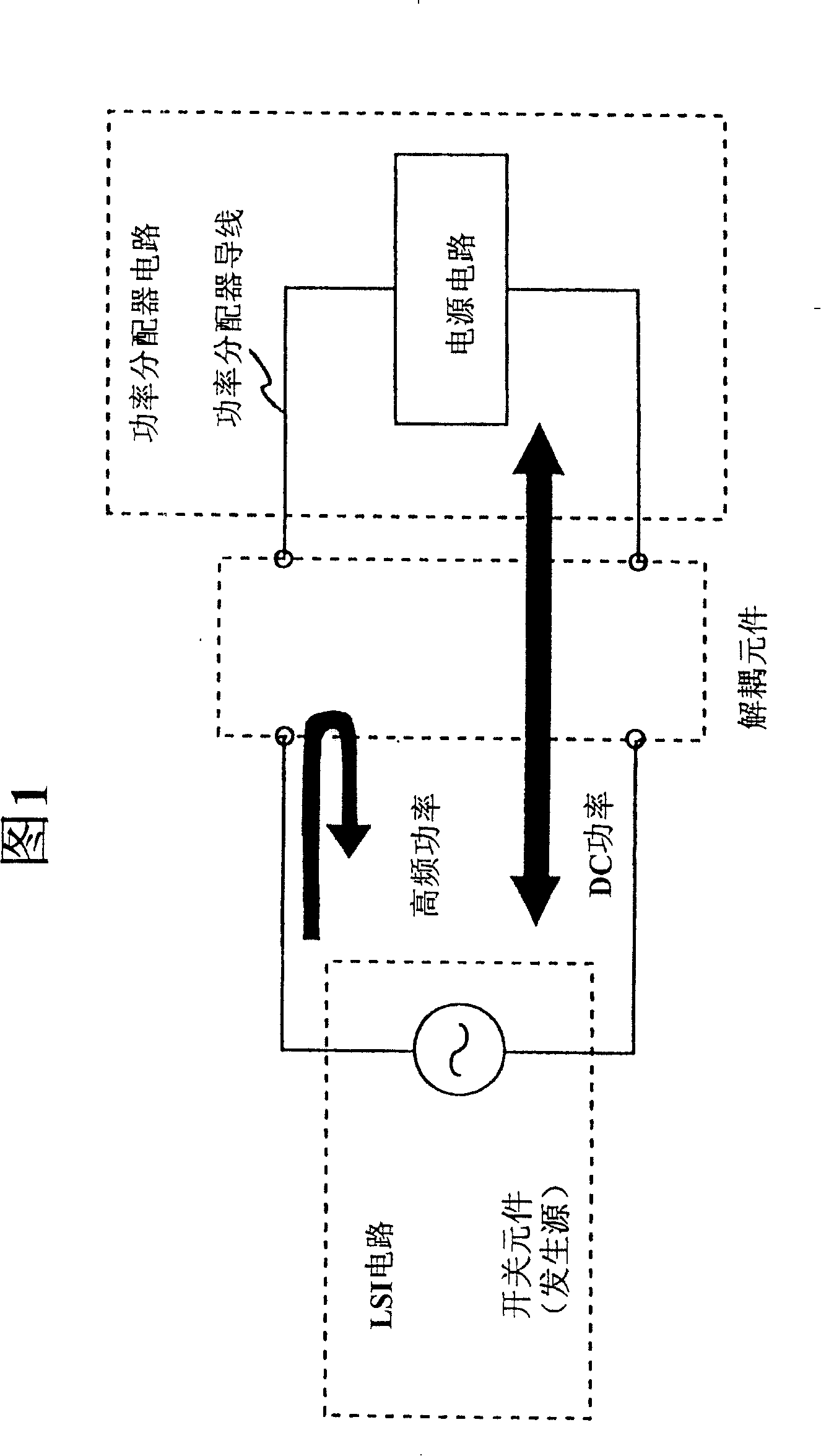

Problems solved by technology

Method used

Image

Examples

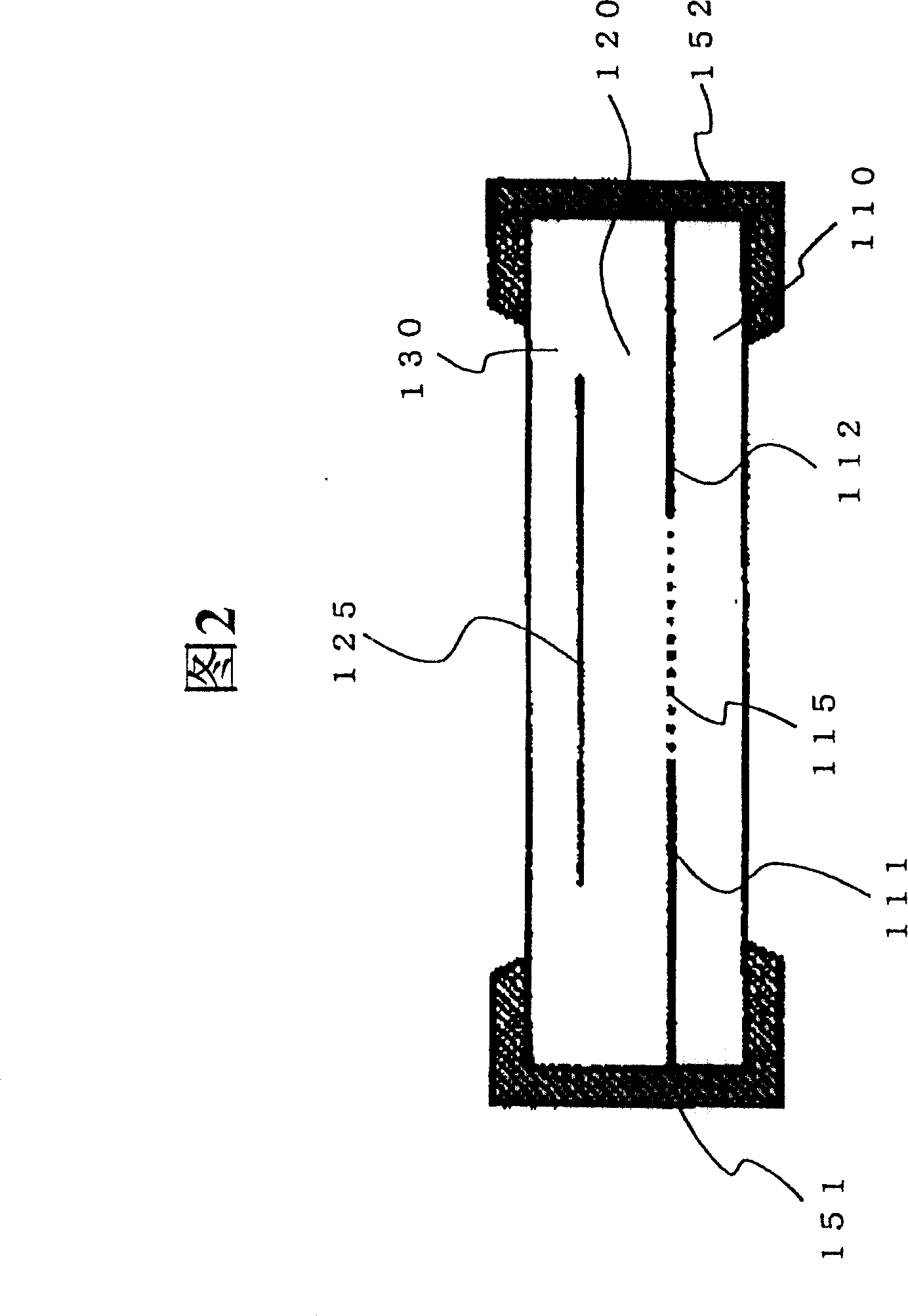

Embodiment 1-1

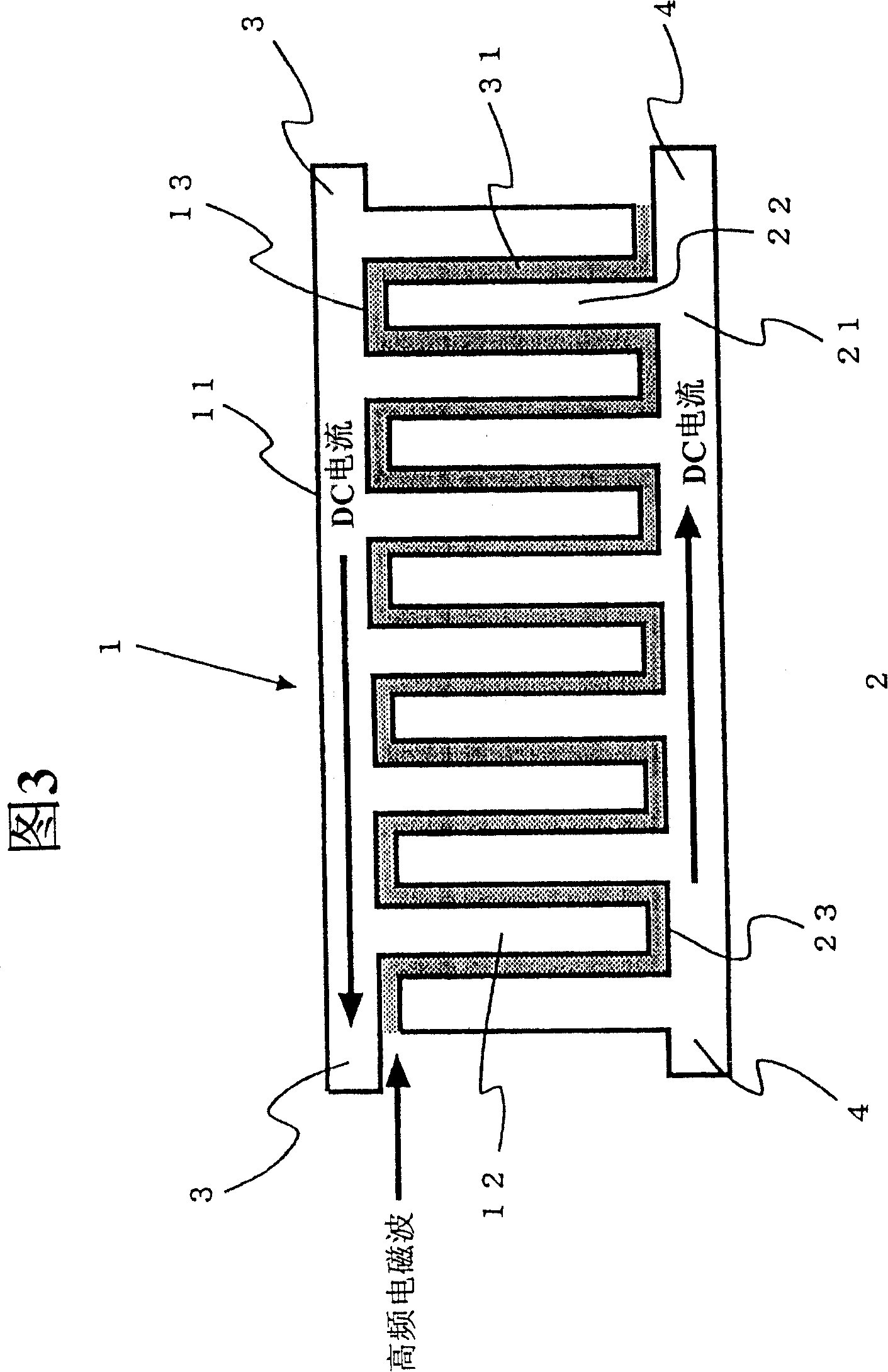

[0100] First, a description will be given of the process of forming the first and second metal members 1 and 2 in which a plurality of protrusions are arranged on one side surface of the plate member (11, 21) in contact with the Stand in a direction substantially normal to the surface. For this purpose, three methods as described below can be used. The first method is a method of punching parallel flat plates using a metal die to form protrusions and depressions. The second method is a method of connecting orthogonal plates as components to parallel plates. That is, a slit is formed on the parallel flat plates, and the vertical plate is engaged with the slit to be fixed thereon using silver paste or the like. Alternatively, secure the parallel plates to the vertical plates by welding. The third method is a method of forming protrusions and depressions by etching. In this method, a metal (for example, an aluminum sheet) is covered with an insulator and coated with a resist ...

Embodiment 1-2

[0107] In a second example of the first embodiment, a methanol solution containing iron (II) dodecylbenzenesulfonate (iron(II) dodecylbenzenesulfonate) with a density of 10 wt.% is prepared in a glass container, and will include The aluminum sheet of Example 1-1 on which the dielectric film 31 was formed was immersed in the solution, and then the aluminum sheet was taken out therefrom. The aluminum sheet was dried in air at room temperature for 30 minutes, and then immersed in an aqueous solution containing pyrrole at a density of 50 wt.%. The aluminum flakes were removed from the solution and kept in air for 30 minutes to allow polymerization of pyrrole. The aluminum pieces were then rinsed in water and methanol and dried at 80°C. This operation was repeatedly performed four times to obtain the aluminum sheet 2 in which the surface of the dielectric film 31 was coated with a conductive polymer of polypyrrole having dodecylbenzenesulfonate as a dopant.

[0108] Produce condu...

Embodiment 1-3

[0112] In a third example of the first embodiment, a solution of polyhexylthiophene (polyhexylthiophene) having a density of 5 wt.% was prepared in a glass container and dropped on the unmasked portion on the aluminum sheet of Example 1-1 and then dried at 80°C. Thereafter, the whole is dipped in an aqueous hydrochloric acid solution to obtain an aluminum sheet, wherein the surface of the dielectric film 31 is coated with the dielectric film 31 including polyhexylthiophene having hydrochloric ions as a dopant as a conductive polymer .

[0113] Generate conductive material layer 3 according to the method similar to embodiment 1-1, to cover that part of aluminum sheet that polyhexylthiophene is formed thereon, connect the first metal member 1 that comprises copper plate, and its parallel plate part 11 Both ends are formed as cathode lead terminals 11a and 11b. Thereafter, the masking resin was dissolved in a similar manner to Example 1-1 to connect the two sets of anode lead ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com