Electric wire bracket for drum washing machine

A technology for drum washing machines and electric wires, which is applied in other washing machines, washing devices, textiles and papermaking, etc., and can solve problems such as weak strength, easy to be broken and damaged, and unable to stably support wire groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

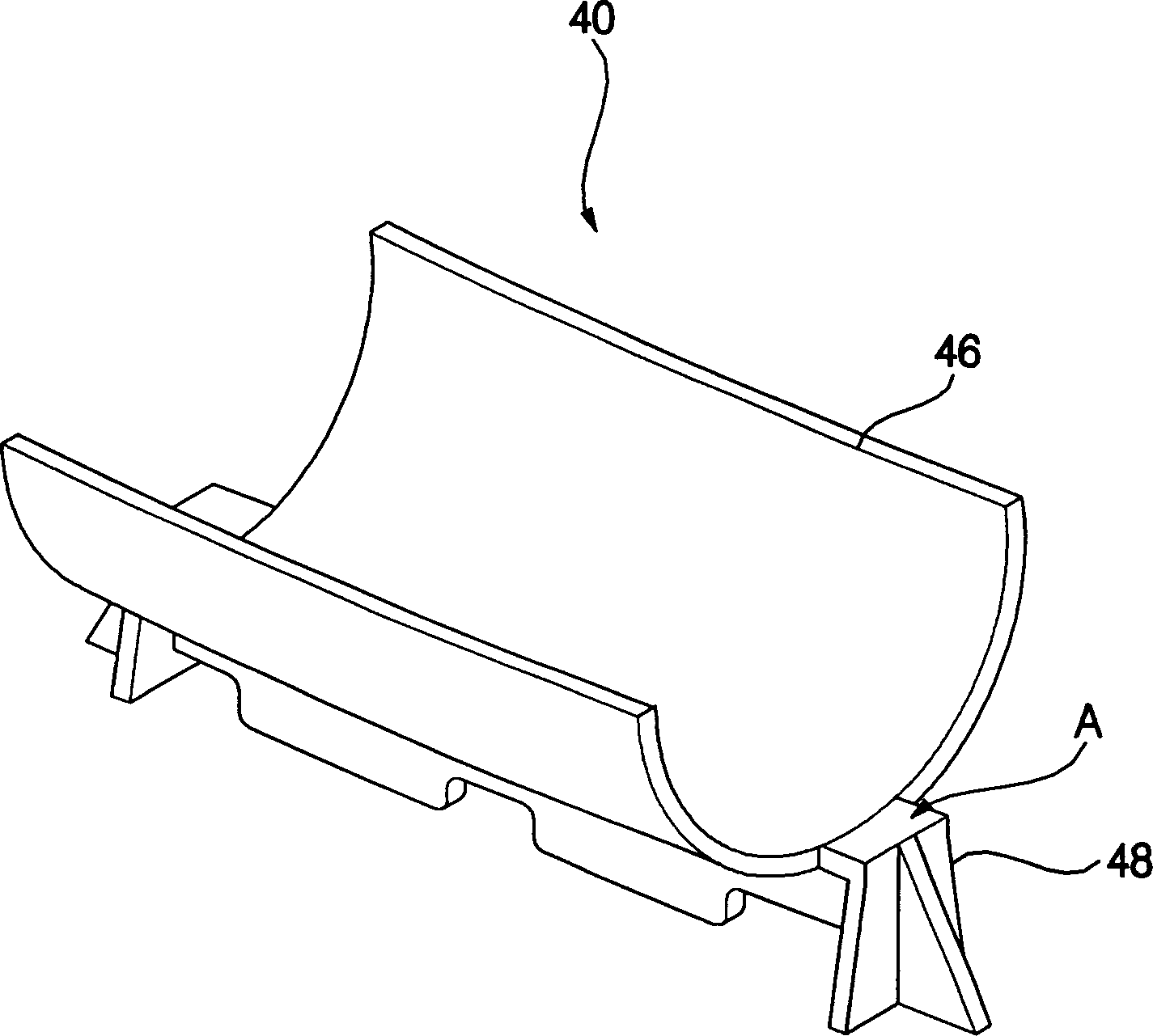

[0030] Such as Figure 4 to Figure 6 As shown, the wire bracket of the present invention is protrudingly formed on the top of the chassis (52) of the drum washing machine (50) in the shape of a box; a mounting portion (62) is formed on the top of the wire bracket, and the mounting portion (62) is used for installing wires. group (70); through holes (64) are respectively formed on the two sides of the wire bracket, and the through holes (64) are used for fixing the connecting wire (80), so that the wire group (70) can be fixed.

[0031] The above-mentioned wire bracket (60) is an injection molded product with a hollow inside, protruding from the top of the chassis (52) with a box shape.

[0032] The installation part (62) is an installation groove for fitting the upper surface of the wire bracket (60) to the lower side, and is formed in a "U"-shaped section along the left-right direction, so that the wire group (70) can be stably installed.

[0033] The above-mentioned through...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap