Linear actuator

A linear actuator and polarity technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of reduced attraction, easy peeling, etc., and achieve the effect of stabilizing the attraction of the stroke direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

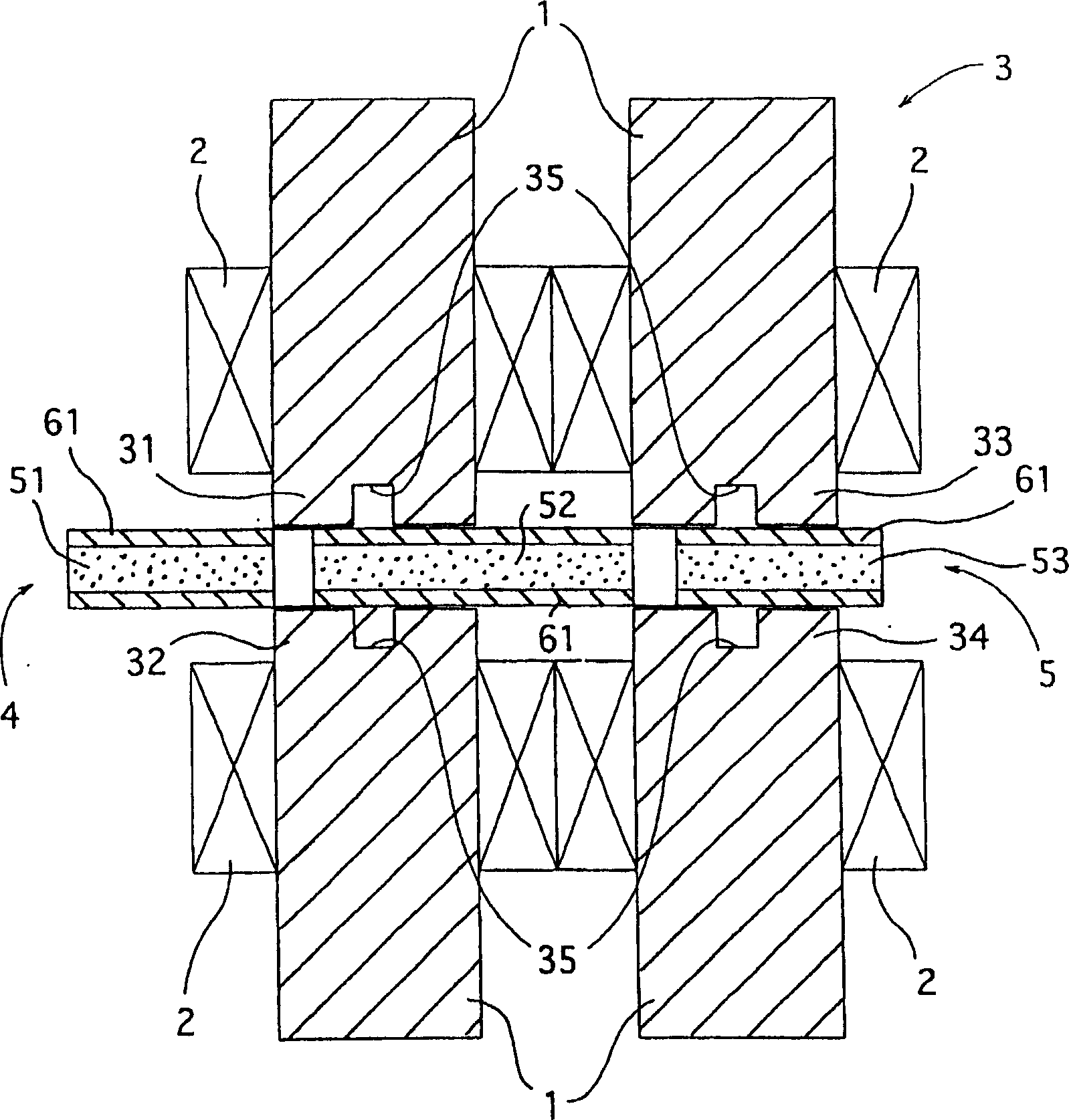

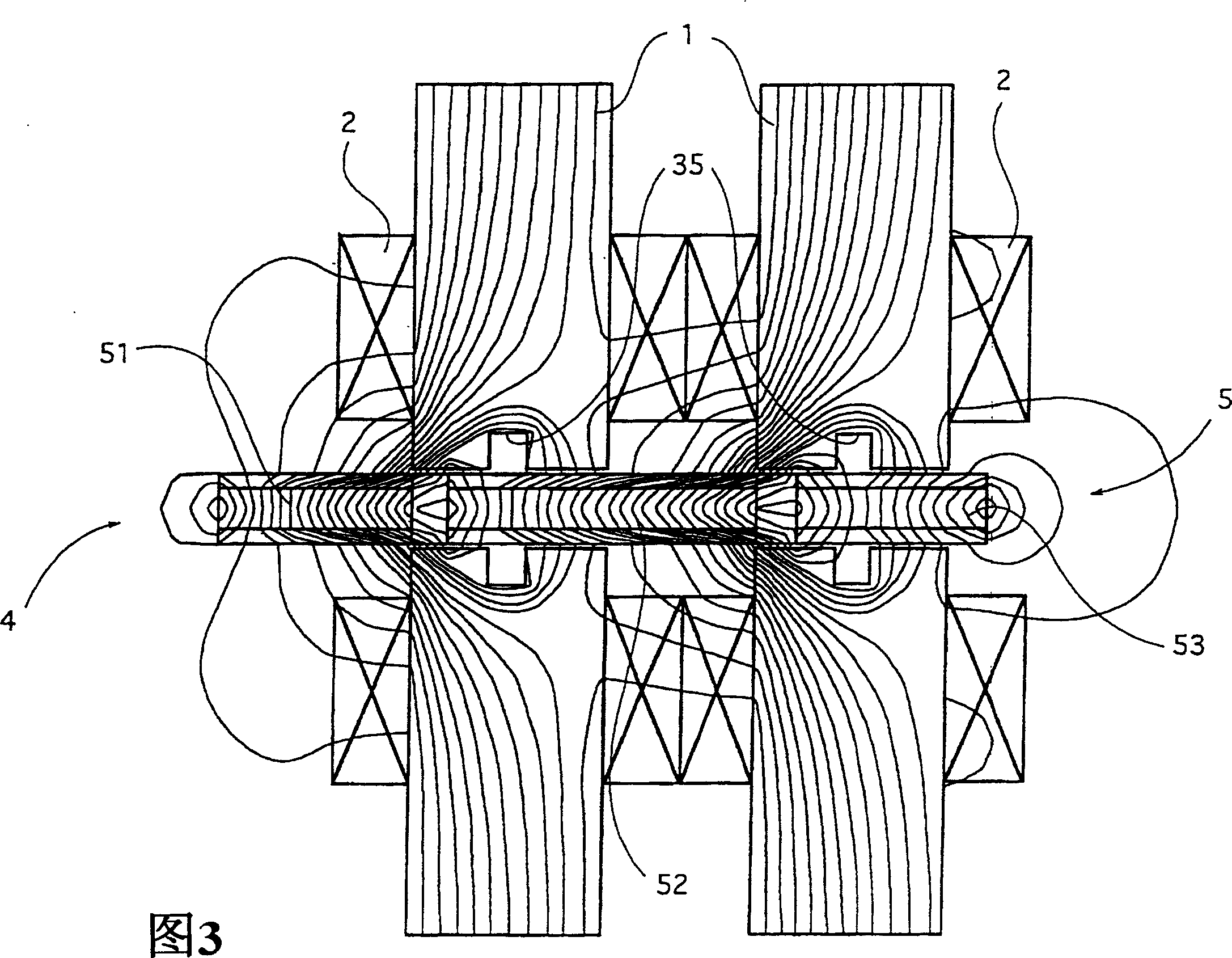

[0056] The linear actuator of the first embodiment such as figure 1 and figure 2 As shown, the magnetic poles 31, 32, 33, 34 of the electromagnet 3 wound with the coil 2 on the iron core 1 of the magnetic material are arranged opposite to each other at a plurality of intervals in accordance with the polarity N and S during the excitation. The magnetic poles of the plurality of permanent magnets 5 arranged in a row in the movable member 4 are arranged at positions facing the plurality of magnetic poles. In this linear actuator, the permanent magnets 5 also extend to the magnetic poles 31, 32 of the electromagnet 3. , 33, 34 other than the relative arrangement.

[0057] In the axial part of the magnetic poles 31, 32, 33, 34 of the above-mentioned electromagnet 3 and the magnetic poles of the above-mentioned permanent magnet 5, a slot portion 35 is formed on the axial part, so that the magnetic poles 31, 32, 33 passing through the above-mentioned electromagnet 3 are formed. ,...

no. 2 Embodiment approach

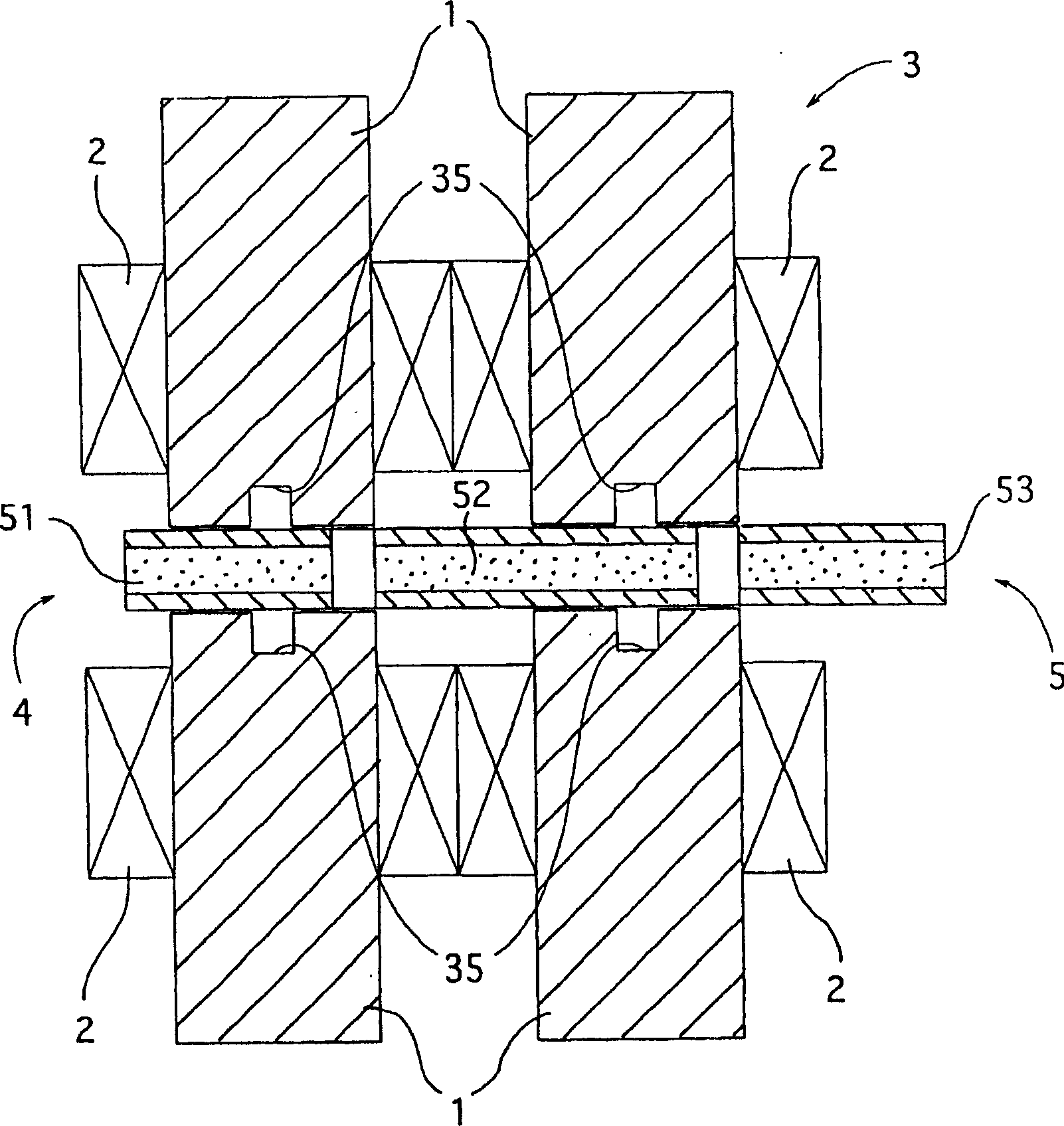

[0077] The linear actuator of the second embodiment such as Picture 1-1As shown in 7, a plurality of magnetic poles 31, 32, 33, 34 of the electromagnet 3 wound with coil 2 are arranged on the iron core 1 of magnetic material in an alternating manner according to the polarity N and S during excitation, and these magnetic poles are opposite to each other. The magnetic poles of the permanent magnet 5 that are only one less than the magnetic poles 31, 32, 33, 34 of the electromagnet 3 are arranged at the position of the electromagnet 3. For the magnetic poles 31, 32, 33, 34 of the above-mentioned electromagnet 3 on the side opposite to the permanent magnet 5 constituting the movable part 4, a magnetic gap at a certain distance is provided between each magnetic pole, and for the magnetic poles of the above-mentioned permanent magnet 5, The magnetic pole of a permanent magnet 52 is straddled between the magnetic poles 31, 32, 33, 34 of the above-mentioned electromagnet 3 during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com