Bias modulation method and system, and plasma processing equipment

A technology of bias voltage modulation and negative bias voltage, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problem of reducing the attractive force of positive ions, reducing the etching rate of the wafer surface, reducing the number and rate of positive ions reaching the wafer surface, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

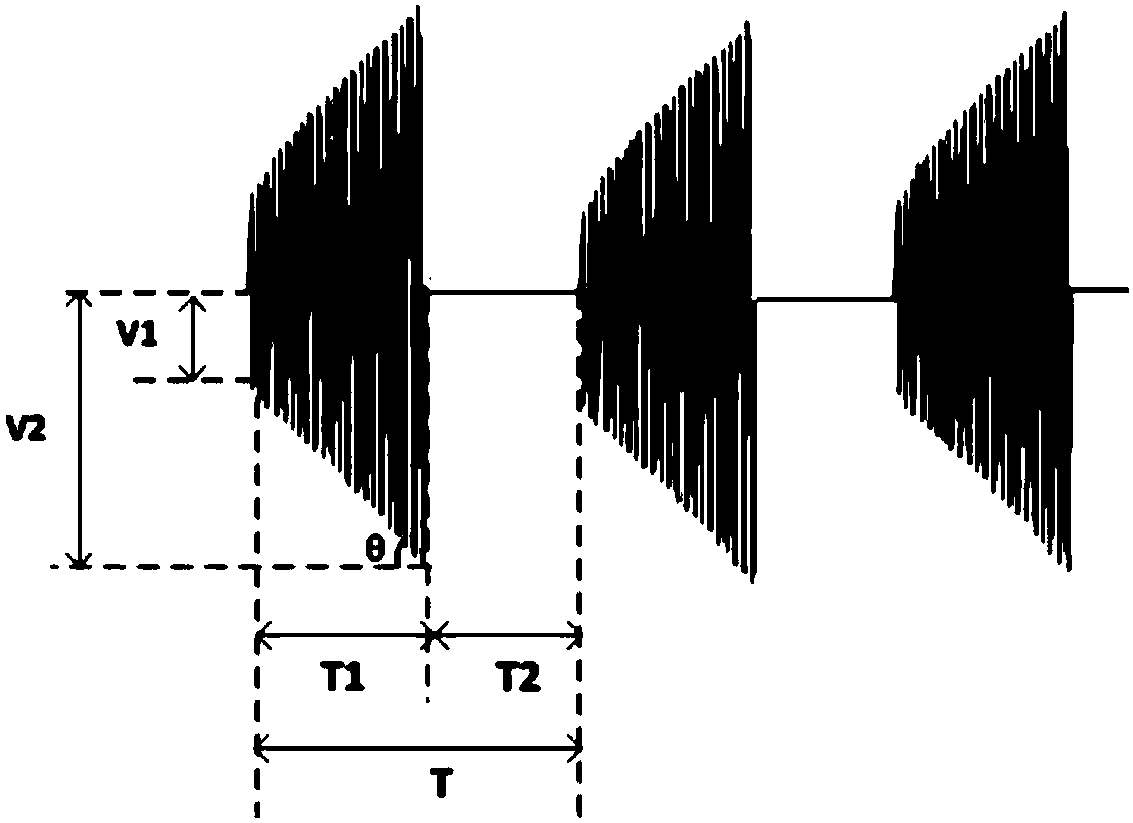

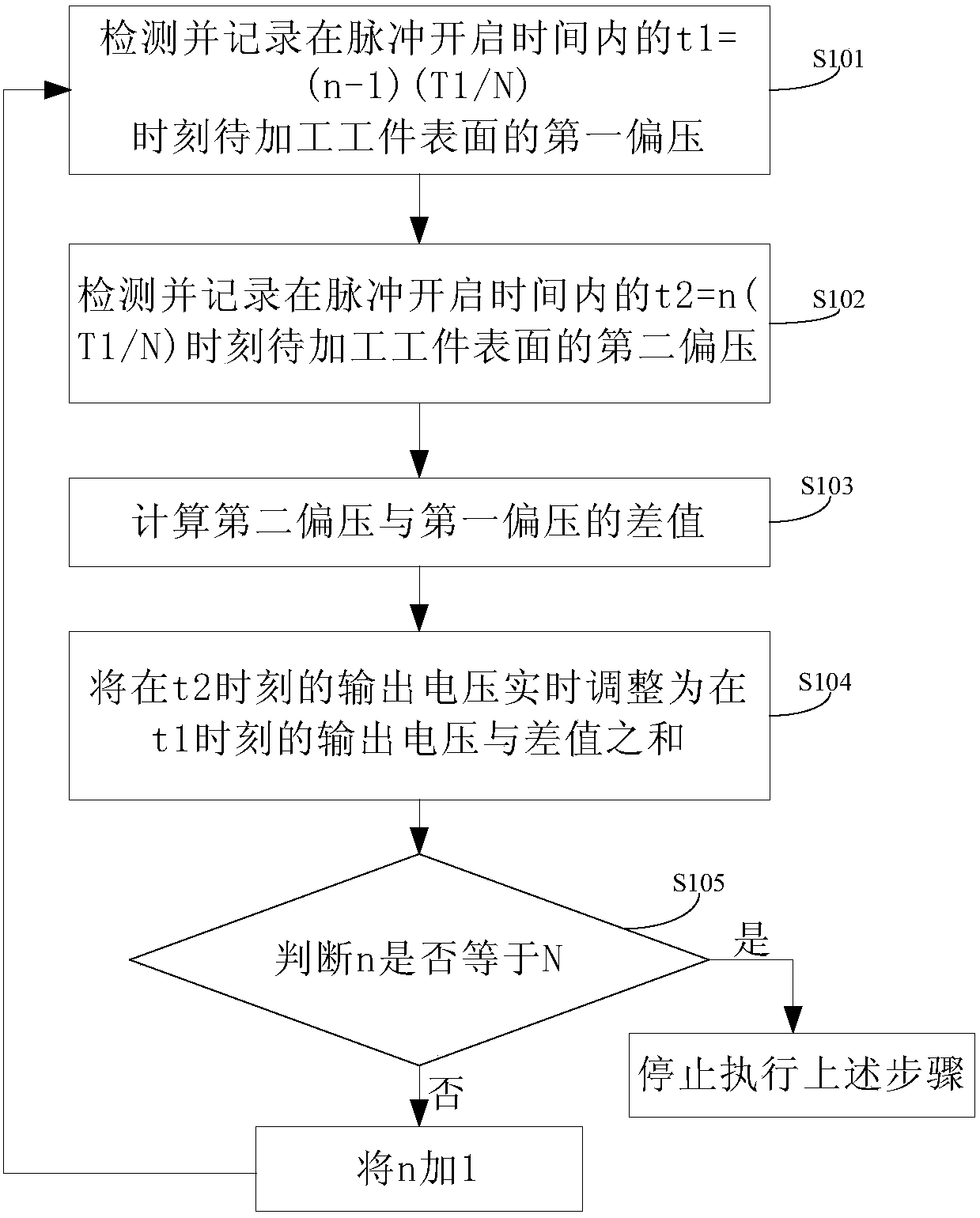

[0051] This embodiment provides a method for modulating the bias voltage on the surface of the workpiece to be processed. The bias power generated by the bias RF source is loaded on the base carrying the workpiece to be processed, so that the surface of the workpiece placed on the base to be processed Generate a negative bias voltage. During the bias power loading period, the voltage generated by the bias RF source increases from the initial voltage to the target voltage to compensate for the negative bias voltage lost on the surface of the workpiece to be processed, so that the negative bias voltage on the surface of the workpiece to be processed is The preset range is maintained during bias power loading.

[0052] Among them, the preset range refers to that after the bias power is loaded on the surface of the workpiece to be processed, it can ensure that the positive ions reaching the surface of the workpiece to be processed have a certain amount and rate, thereby ensuring th...

Embodiment 2

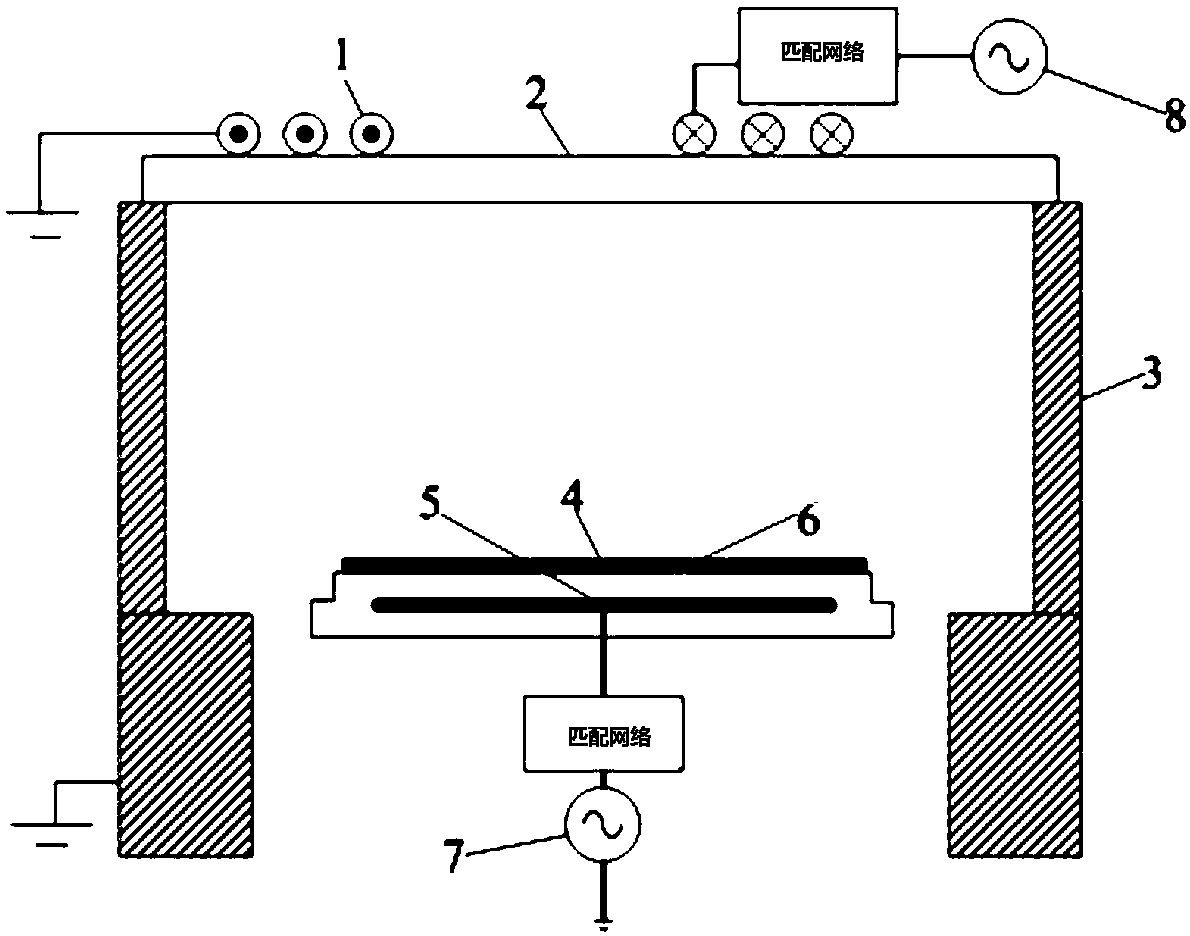

[0075] This embodiment provides a bias modulation system, such as Figure 5 As shown, it is used to modulate the negative bias voltage of the workpiece to be processed placed on the surface of the base 10, including: a bias RF source 7, the bias RF source 7 is electrically connected to the base 10 carrying the workpiece to be processed, for A bias power is applied to the base 10 to generate a negative bias on the surface of the workpiece to be processed. The voltage adjustment module 9, the voltage adjustment module 9 is electrically connected to the bias RF source 7, and is used to increase the voltage generated by the bias RF source 7 from the initial voltage to the target voltage during bias power loading, so as to compensate the surface of the workpiece to be processed Loss of negative bias voltage, so that the negative bias voltage of the surface of the workpiece to be processed is kept within the preset range.

[0076] The voltage adjustment module 9 can make the increa...

Embodiment 3

[0086] This embodiment provides a plasma processing device, including a base for carrying workpieces to be processed, a plasma generating device, and the bias modulation system in Embodiment 2, where the bias modulation system is electrically connected to the base.

[0087] Wherein, the plasma generating device includes a coil and an upper electrode radio frequency source connected thereto, and the upper electrode radio frequency source is a continuous wave radio frequency source or a pulse modulation radio frequency source.

[0088] By adopting the bias voltage modulation system in Embodiment 2, the plasma processing equipment can reduce or avoid the loss of negative bias voltage on the surface of the workpiece to be processed, thereby reducing or avoiding the loss of plasma energy bombarded to the surface of the workpiece to be processed , so that the processing rate of the processed workpiece is kept within the preset range, on the one hand, the productivity of the processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com