Rapid gel breaker for treating xanthan gum system oil sludge emulsion as well as preparation method and application of rapid gel breaker

A gel breaker and sewage sludge technology, which is applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of no attention to dehydration rate, long stirring time for demulsification, and low oil recovery rate To achieve the effect of enhancing water solubility and adsorption capacity, enhancing demulsification and degreasing effect, and reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

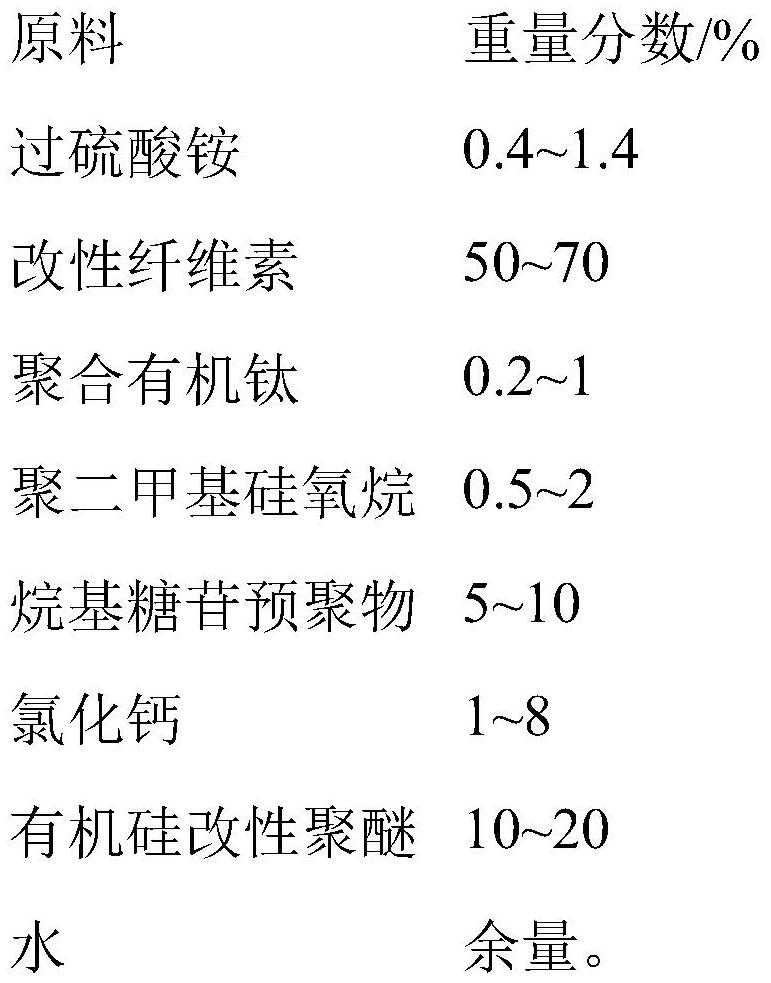

[0029] A kind of quick breaker that is used for xanthan gum system sewage sludge emulsion treatment, by weight percentage, is made of following components:

[0030]

[0031] The preparation method of described quick breaker is as follows:

[0032] (1) Preparation of mixture A: Weigh 6g of calcium chloride, 9g of alkyl glycoside prepolymer, and 18g of silicone-modified polyether, add them into deionized water, and stir at 50°C for 15min to obtain mixture A;

[0033] Among them, the preparation of silicone-modified polyether includes the following steps: Weigh 120g of allyl polyether and 40g of hydrogen-containing silicone oil, add 0.3g of chloroplatinic acid and react at 90°C for 2h, then add 14g of allylsulfonic acid Na, continue to react at 90°C for 50 minutes to obtain the silicone-modified polyether;

[0034] Wherein, the preparation of the alkyl glycoside prepolymer includes the following steps: mixing 9 g of alkyl glycoside with 9 g of water, then raising the temperat...

Embodiment 2

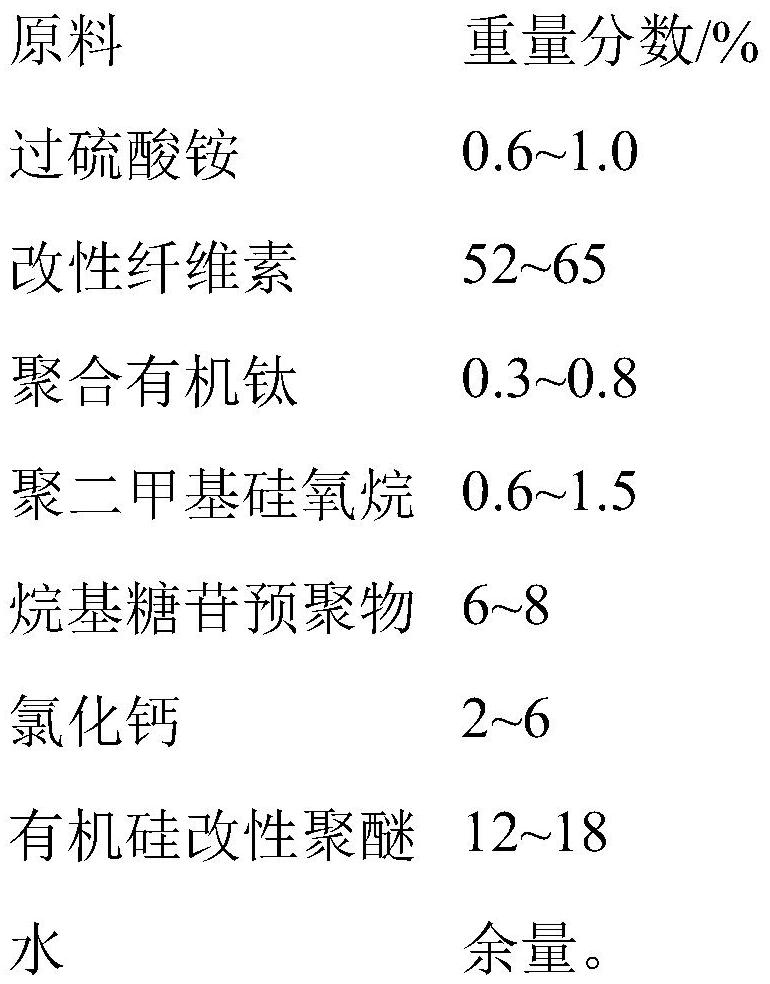

[0040] A kind of quick breaker that is used for xanthan gum system sewage sludge emulsion treatment, by weight percentage, is made of following components:

[0041]

[0042]

[0043] The preparation method of described quick breaker is as follows:

[0044] (1) Preparation of mixture A: Weigh 5g of calcium chloride, 10g of alkyl glycoside prepolymer, and 17g of silicone-modified polyether respectively, add them into deionized water, and stir at 50°C for 20min to obtain mixture A;

[0045] Wherein, the preparation of the alkyl glycoside prepolymer includes the following steps: mixing 9 g of alkyl glycoside with 9 g of water, then raising the temperature to 40° C. and keeping it warm for 45 minutes; then raising the temperature to 85° C. and keeping it warm for 70 minutes, and cooling to room temperature to obtain the product;

[0046] Among them, the preparation of silicone-modified polyether includes the following steps: Weigh 120g of allyl polyether and 40g of hydrogen-c...

Embodiment 3

[0052]A kind of quick breaker that is used for xanthan gum system sewage sludge emulsion treatment, by weight percentage, is made of following components:

[0053]

[0054]

[0055] The preparation method of described quick breaker is as follows:

[0056] (1) Preparation of mixture A: Weigh 7g of calcium chloride, 5g of alkyl glycoside prepolymer, and 15g of silicone-modified polyether, add them into deionized water, and stir at 50°C for 25min to obtain mixture A;

[0057] Wherein, the preparation of the alkyl glycoside prepolymer includes the following steps: mixing 9 g of alkyl glycoside with 9 g of water, then raising the temperature to 40° C. and keeping it warm for 45 minutes; then raising the temperature to 85° C. and keeping it warm for 70 minutes, and cooling to room temperature to obtain the product;

[0058] Among them, the preparation of silicone-modified polyether includes the following steps: Weigh 120g of allyl polyether and 40g of hydrogen-containing silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com