Boiler

A boiler and fan technology, applied in the field of gas heating boilers, can solve the problems of complex and heavy heat exchangers, and achieve the effect of high overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

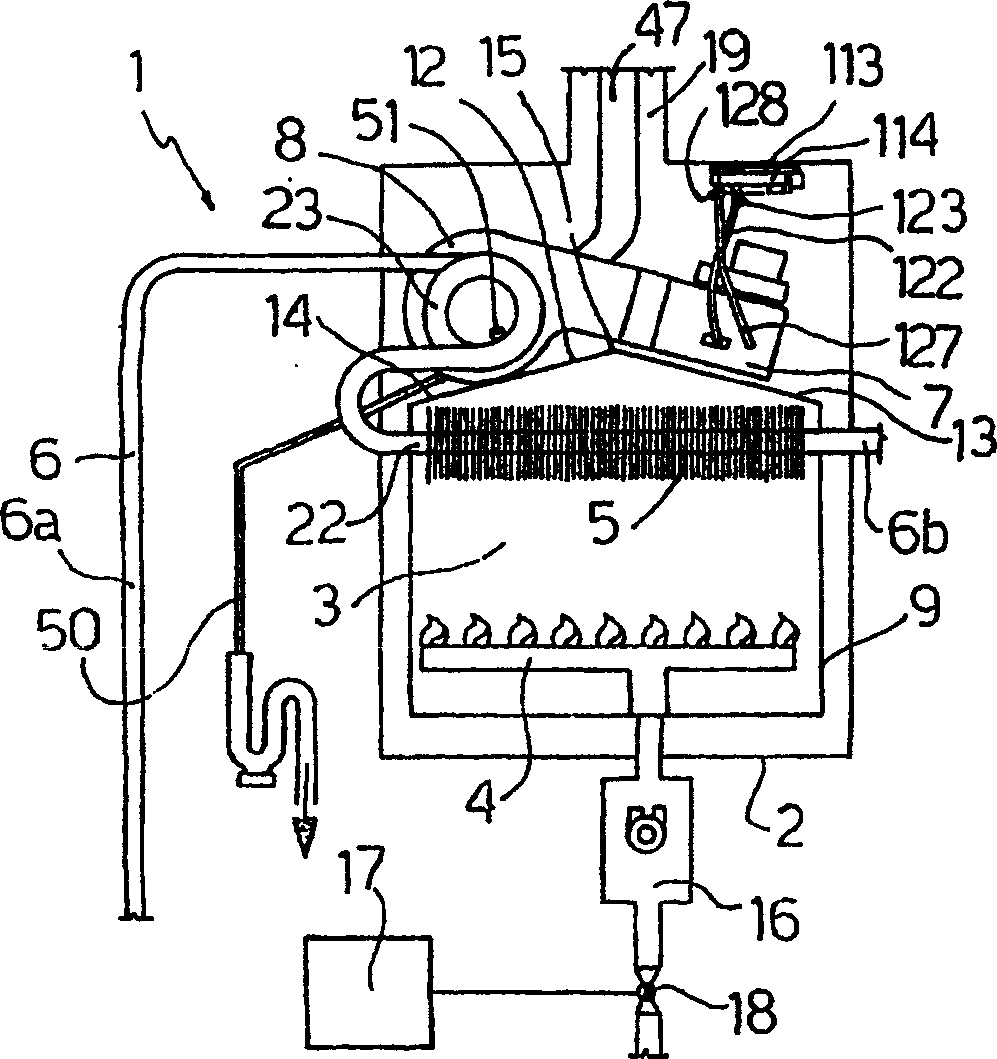

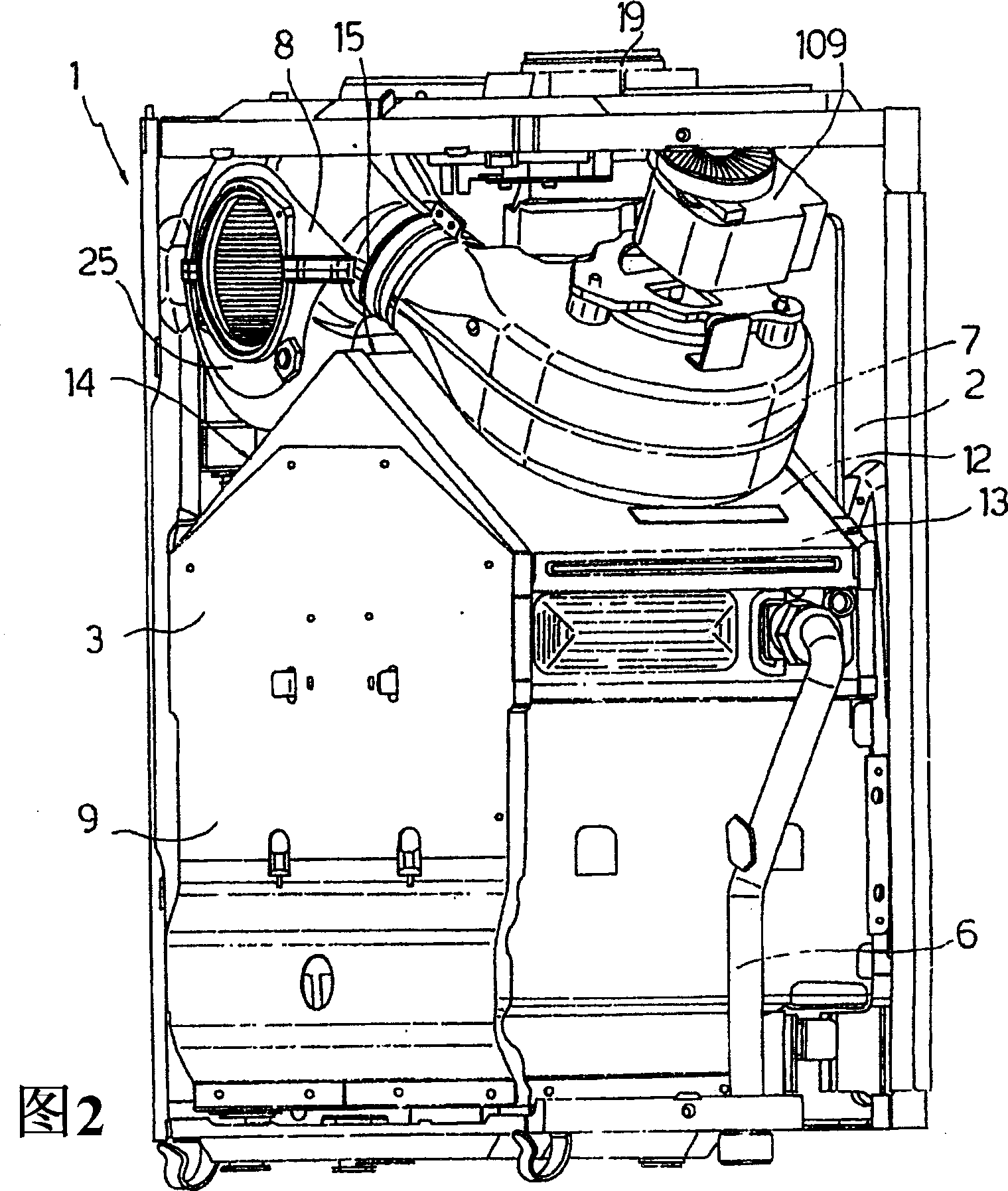

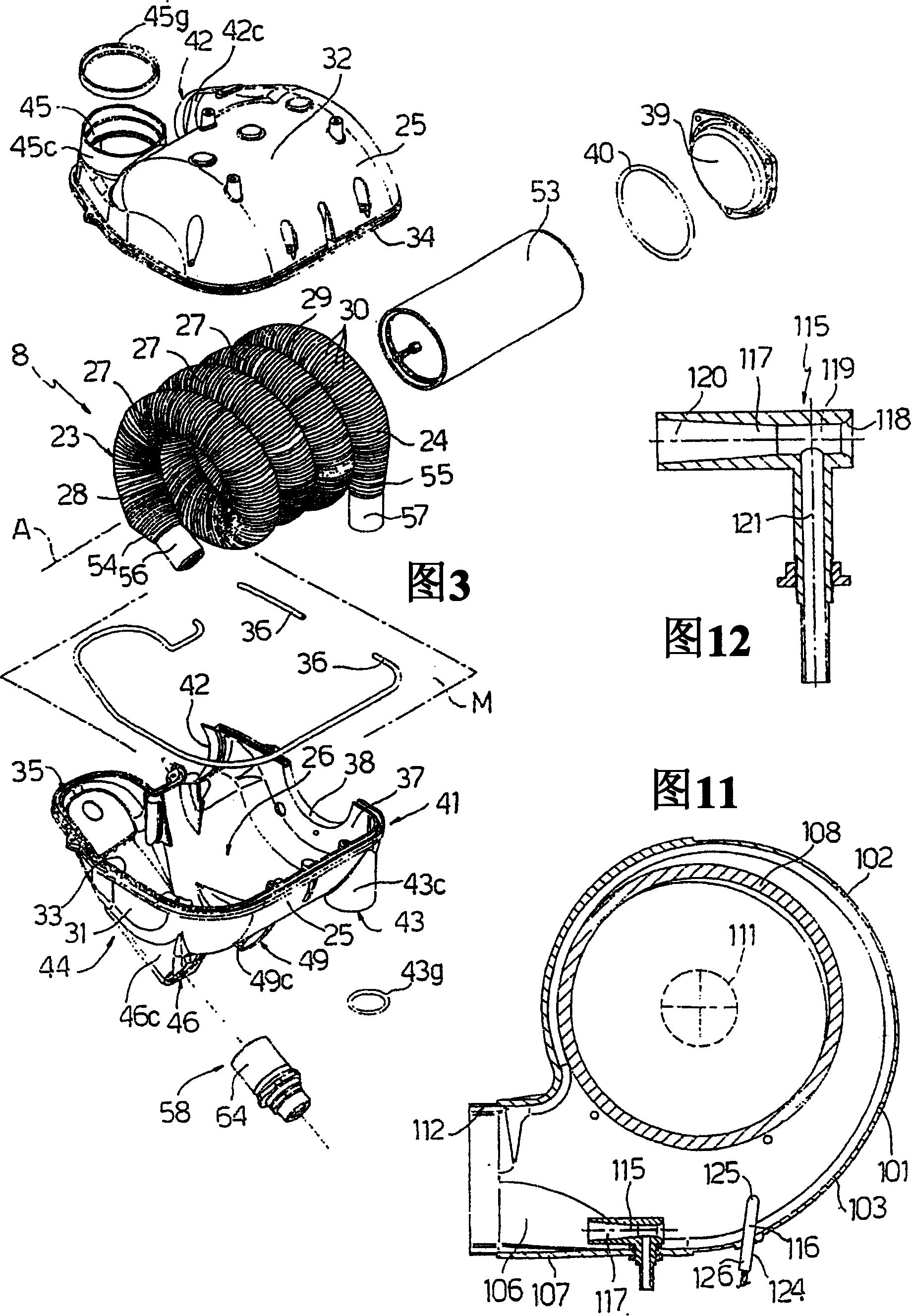

[0024] refer to figure 1 and 2, a boiler 1, especially a wall-mounted condensing heating boiler, comprising: an airtight enclosure 2 containing a combustion chamber 3 associated with a gas burner 4; for transferring the heat of the fumes in the combustion chamber 3 to In the known loop 6 (for simplicity only in figure 1 Shown in part) is a primary heat exchanger 5 for circulating heating fluid; a smoke circulation fan 7; and a secondary heat exchanger 8 for recovering potential condensation heat from the smoke. A primary heat exchanger 5, a fan 7, and a secondary heat exchanger 8 are arranged in series with the combustion chamber 3 along the smoke path.

[0025] The combustion chamber 3 is delimited by a furnace jacket 9 which is hermetically closed relative to the casing 2 and which houses the burner 4 and the primary heat exchanger 5 . The furnace jacket 9 comprises a substantially rectangularly supported prism having a triangular roof-shaped top wall 12 formed by two incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com