Ring iron core reactor

A toroidal core and reactor technology, applied in inductors, fixed inductors, transformer/inductor magnetic cores, etc., can solve the problems of great environmental impact, cumbersome processing of iron cores, unstable quality, etc., to reduce pollution and save energy. The effect of occupying space and reducing infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

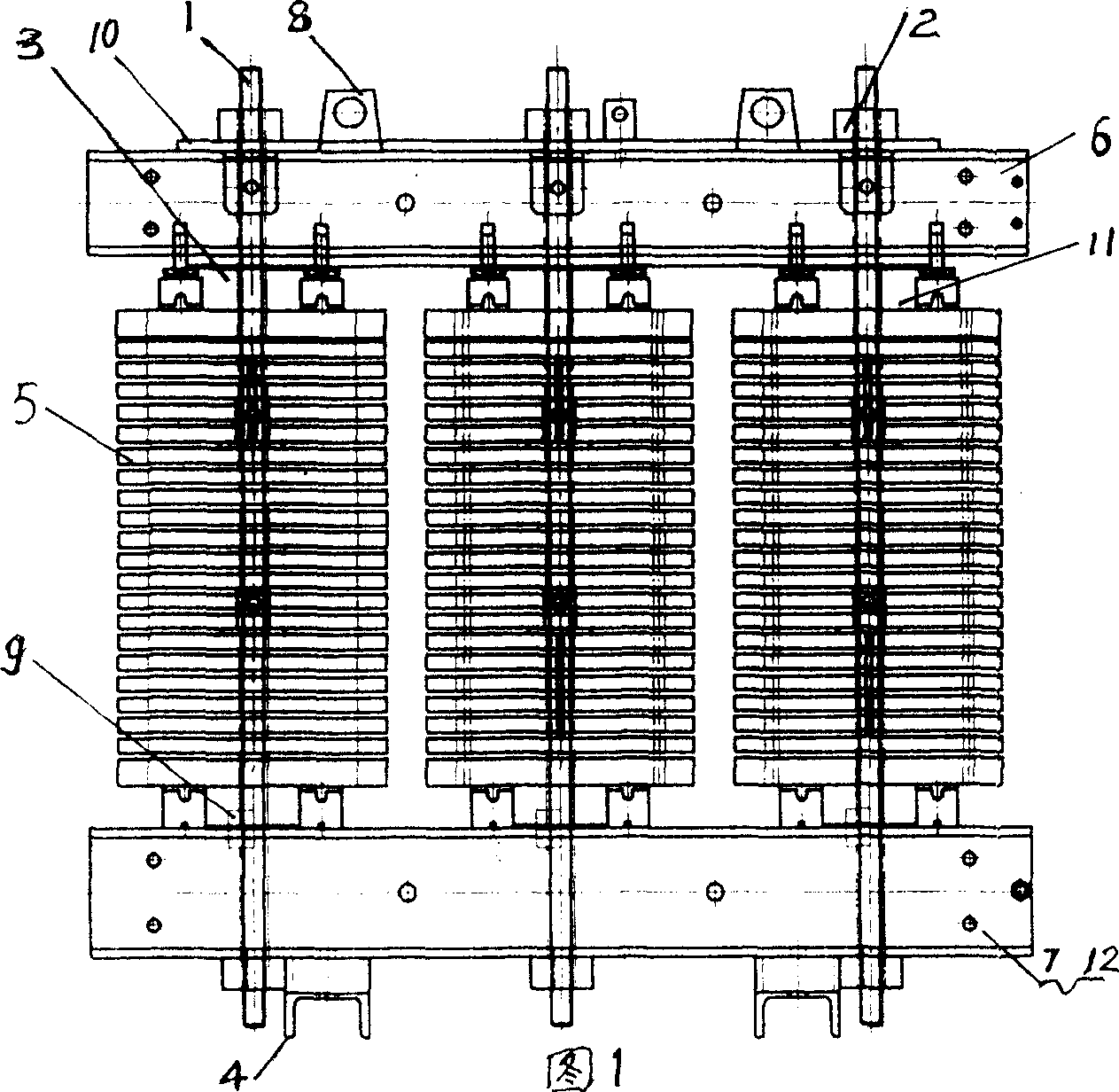

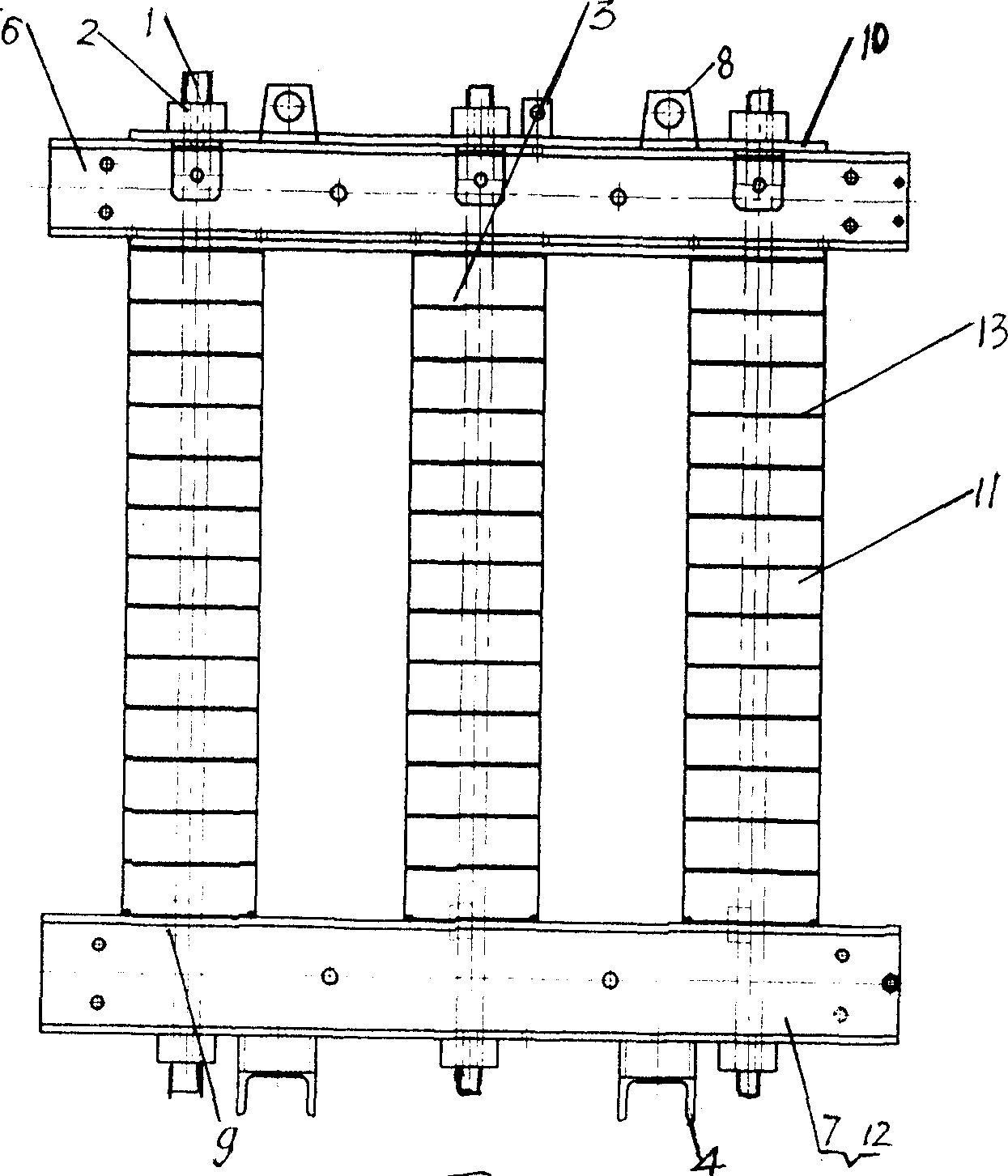

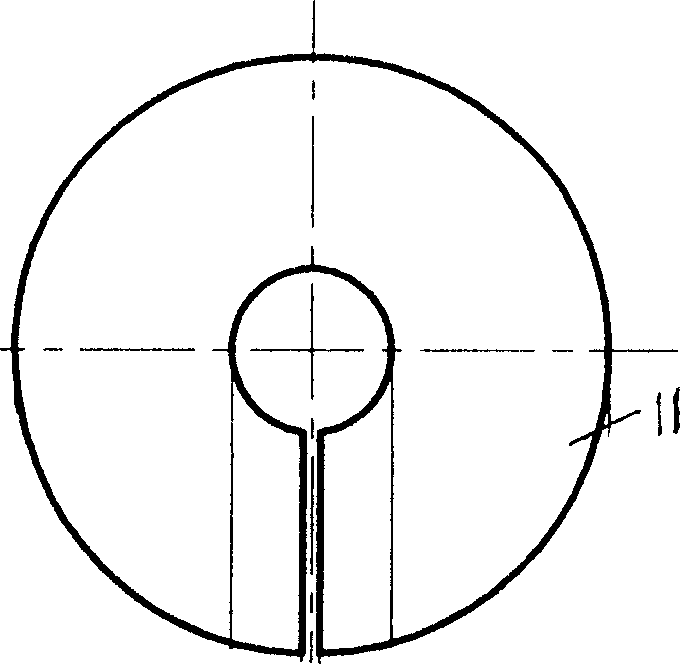

[0018] See Figure 1 and figure 2 , a ring-shaped core reactor, which includes an iron core 3 and a coil 5, an upper clamp 6, a lower clamp 7, a lifting ring 8, and a foot 4, and the iron core 3 is formed by winding a silicon steel sheet with high magnetic permeability with grain orientation It is formed by stacking discus 11 formed by high temperature annealing. Each discus 11 has a small air gap 13 separated by an insulating backing plate. Between each discus 11 and between the lower first discus 11 and the lower iron yoke 12. The ground piece 9 is connected, and the upper iron yoke 10 is placed on the first discus 11 of the upper part, and the upper iron yoke 10, the lower iron yoke 12 and the discus 11 are tightened with a stainless steel screw 1, and the upper iron yoke 10, the lower iron yoke 12 and the discus 11 It becomes a whole after dipping C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com