Mounted assemblies for aircraft, wheels and tires

A technology for installing components and tires, applied to tire parts, tire rims, rims, etc., can solve problems such as length, and achieve the effect of reducing fuel consumption, simple and fast implementation of tools and skills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

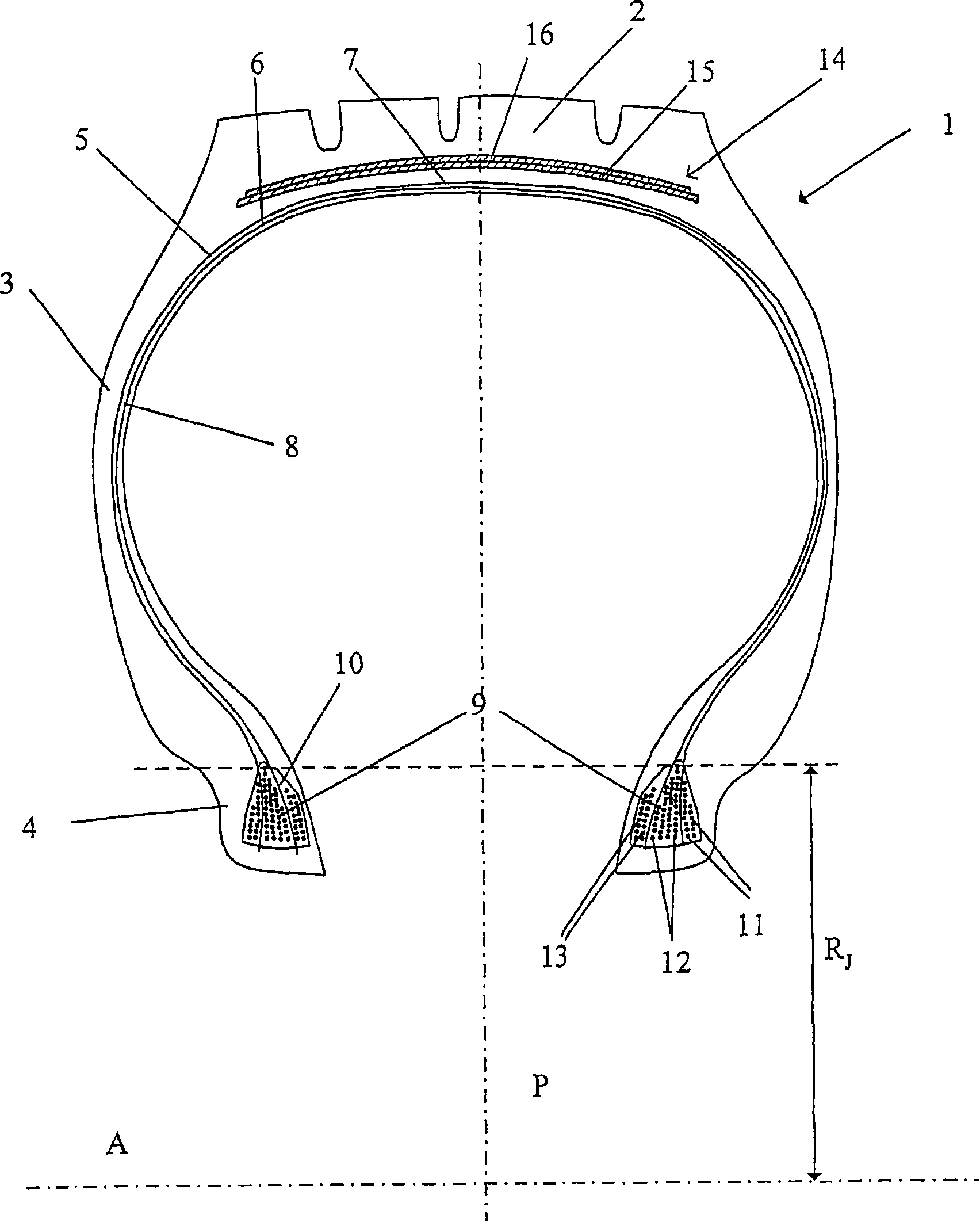

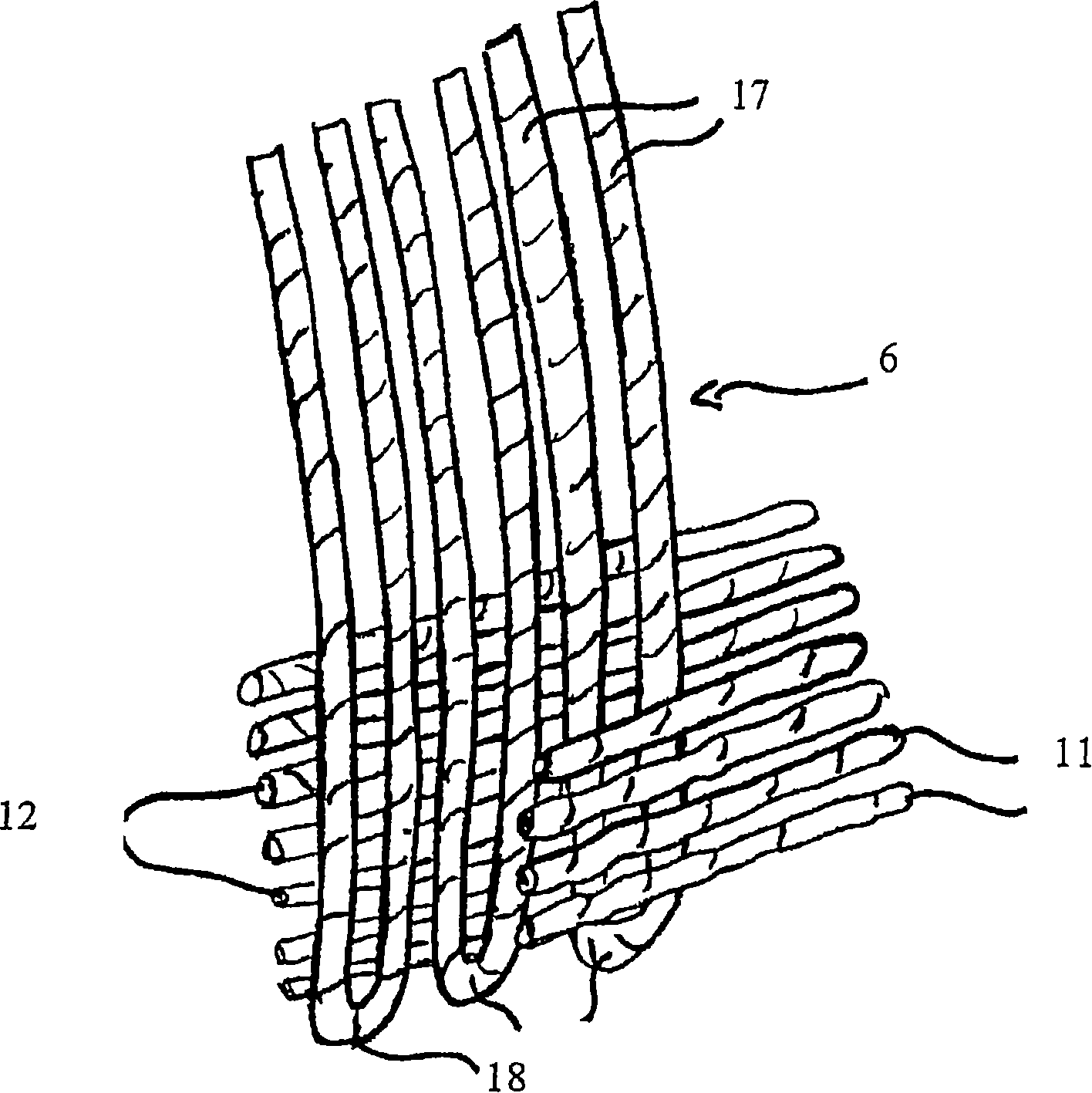

[0134] like figure 1 The aircraft tire 1 shown in the mid-axis half-section view includes a crown 2 , two sidewalls 3 , and two beads 4 . The carcass reinforcement 5 extends from one bead 4 to the other and consists of two circumferential arrangements 6 and 7 of reinforcing elements. The circumferential arrays 6 and 7 of reinforcing elements are positioned radially in the side wall 3 and consist of aramid or aramid reinforcing elements. The reinforcing elements are arranged parallel to each other and separated by a layer of compound 8 whose properties and modulus depend on its position in the tyre.

[0135] The fixation of the two circumferential arrays 6 and 7 in the bead 3 is effected by circumferentially arrayed reinforcement strands or “strands” 9 arranged axially on both sides of each circumferential array 6 and 7 . Each circumferentially arranged reinforcing strand or strands 9 can be obtained by helically winding one strand. The radial reinforcing elements and the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com