Washing method of tumbling washing machine

The technology of a drum washing machine and washing method is applied to the control device of washing machine, washing device, textile and paper making, etc., which can solve the problems of increased time consumption, power consumption, low concentration of washing liquid, etc., so as to reduce washing time and improve detergent. Active, good power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

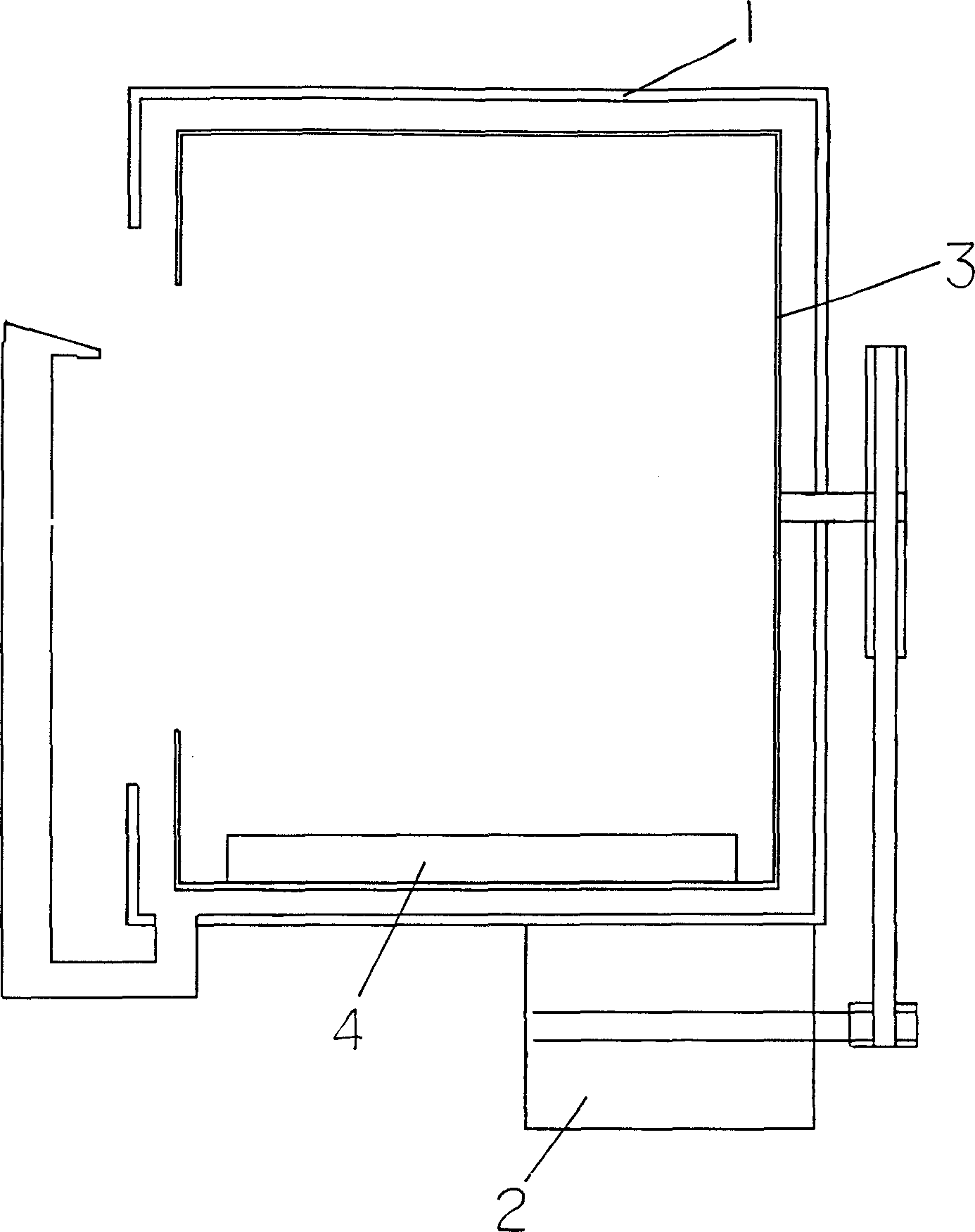

Image

Examples

Embodiment 1

[0016] After the laundry is put into the inner cylinder 3 of the washing tub, the three processes of washing, rinsing and dehydration are completed in sequence, wherein the rinsing and dehydration processes are set in a conventional manner in the prior art. In this embodiment, the different It is a washing process, and the specific process of this process is as follows:

[0017] 1. Put the laundry into the inner cylinder 3, add detergent, and then wash in stages;

[0018] 2. The first stage: Inject water not exceeding 90% of the total amount of washing water into the cylinder, and then wash with the rotation of the inner cylinder and circulating spray water. The washing time can be set to 6-80 minutes;

[0019] 3. The second stage: pour water into the cylinder until the amount of washing water is reached, and then wash with the rotation of the inner cylinder and circulating spray water. The washing time can be set to 3-20 minutes;

[0020] 4. Drainage and dehydration: take of...

Embodiment 2

[0023] The difference from the above-mentioned embodiment 1 is that in this embodiment, the staged washing in the washing process is divided into three stages, which are specifically set as:

[0024] The first stage: Inject water not exceeding 80% of the total amount of washing water into the cylinder, and then wash with the rotation of the inner cylinder 3 and the circulating spray water. The washing time can be set to 6-70 minutes; in this stage, the amount of washing liquid Less, high concentration, the laundry is wetted by the washing liquid, and the concentration of dirt in the laundry is also high at this time.

[0025] The second stage: inject water into the cylinder, control the amount of water in the inner cylinder to not exceed 90% of the total amount of washing water, and then wash with the rotation of the inner cylinder and circulating spray water. The washing time can be set to 3-40 minutes; this stage requires Let the washing liquid fully infiltrate the washing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com