Sluice valve dual stem mechanism

A double-stem and gate valve technology, which is applied in the direction of sliding valves, valve devices, mechanical equipment, etc., can solve the problems of large space occupation, high space occupied by the valve stem lifting mechanism, and limited use, so as to achieve improved service life, stable operation, Avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

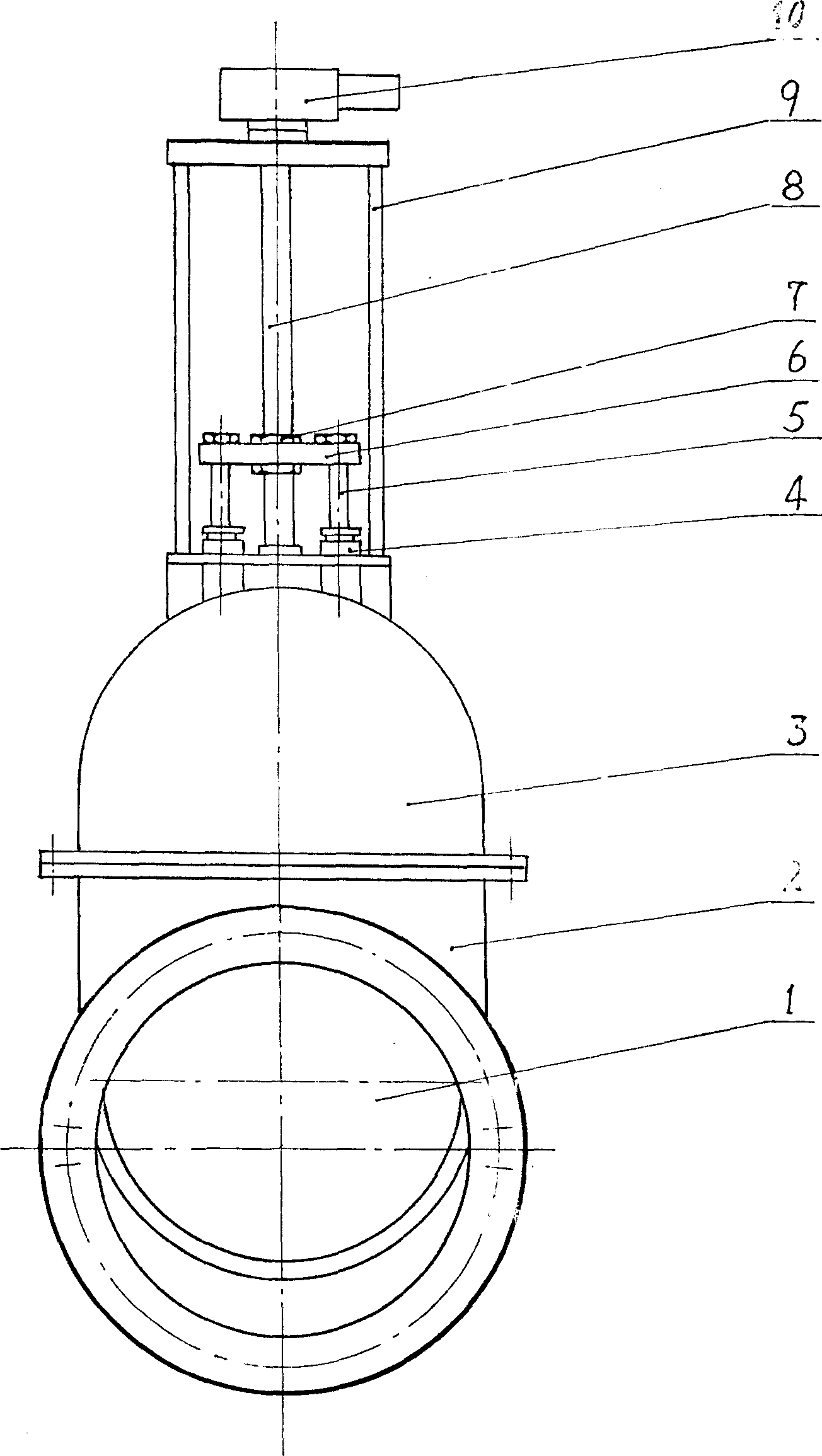

[0011] Such as figure 1 As shown, the valve cover 3 is connected to the upper part of the valve body 2, and the gate plate 1 is installed in the valve body 2. This double valve rod mechanism is that the top of valve cover 3 is connected with the support 9 of a frame structure, and screw rod 8 is equipped with in the support middle part, and the upper end of screw rod passes support 9, and is screwed in the driving device 10 that is fixed on the support top. The driving device 10 can be an electric driving device driven by a motor, or a manual driving device including a hand wheel. The connecting piece 6 is flat, and a nut 7 is connected to the central hole in the middle, and the nut 7 is screwed and matched with the screw rod 8 . Both sides of the connecting piece 6 are fixedly connected to the top of a valve stem 5 respectively, and the two valve stems 5 should be kept parallel so as to drive the gate to go up and down smoothly. The lower end of the valve stem is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com